Ventilation butterfly valve installation instructions

Ventilation butterfly valve installation | instructions for use

Instructions for use of the ventilation butterfly valve:

The structural design of the ventilation butterfly valve should be combined with the operating conditions of the valve.

ventilation butterfly valve (2)

1. Under the smelting conditions with high temperature and high dust content, the design of the ventilation butterfly valve can adopt a flat inclined plate structure. There is a gap between the butterfly plate and the valve body of this structure. The gap value is based on the valve diameter and workmanship. The operating conditions are determined, and generally controlled within 0.5% of the channel area, which can meet the requirements of the ventilation butterfly valve installation, temperature changes in working conditions, and melting process requirements. To

2. Under the condition of high temperature and low dust content, the design of the ventilation butterfly valve can adopt the vertical plate structure. The sealing surface of the structure is easy to process, and the gap value of the sealing surface is controlled within 0.2% of the channel area. The dimensional accuracy of the valve body and butterfly plate sealing pair can meet the design requirements through mechanical processing.

3. For working conditions with high temperature, low pressure and strict sealing requirements, the design of the ventilation butterfly valve adopts a lever-type plane structure. The sealing pair preparation and butterfly plate running track can meet the technological requirements of high sealing performance pipe network equipment.

The main body seal of the ventilation butterfly valve selects different structures according to different working conditions, which is conducive to the production and use of the valve. The shaft end structure design of the ventilating butterfly valve adopts an external support structure with excellent heat insulation and sealing effects, which can realize the function of sealing the second shaft end of the valve and then supporting it, which is convenient for adjustment, and will not cause shaft end jam. When the direct connection or the crank connecting rod mechanism is connected with the transmission mechanism, the installation of the heat insulation sleeve can effectively keep away the influence of the high temperature environment on the transmission device and ensure the normal operation of the valve. The valve body and butterfly plate of the large-diameter ventilating butterfly valve should be cast or welded according to the requirements of the working conditions, and ribs should be configured, and reasonable process plans and materials should be selected to improve the rigidity of the product and prevent product deformation.

Precautions for installation of ventilation butterfly valve:

The installation position of the ventilation butterfly valve in the pipe network and the pipe network layout also affect the use of the valve. The closed funnel is designed at the opening end of the valve or the corner of the valve connection for the pipe with large smoke and dust. Regular dust removal can prevent excessive dust accumulation, which is beneficial The rotation of the butterfly board. There are several issues that should be paid attention to when installing the ventilation butterfly valve.

1. The use of metal gaskets must ensure that the load is uniform, and avoid the additional pressure of the valve due to the influence of temperature and self-weight or the stress caused by welding, and the deformation of the valve flange and pipeline.

2. When the valve is installed in a place with a long pipeline, a support frame should be installed.

3. The valve installation should pay attention to the medium flow direction, so that the opening direction of the butterfly plate is consistent with the pipeline medium flow direction, which is beneficial to the self-cleaning effect of the medium flow rate.

4. Strengthen the protection of the overall insulation layer of the pipe network so that the pipe wall temperature is above the dew point, which can reduce the low-temperature cohesive dust accumulation. If the pipe wall temperature is higher than the acid dew point of the flue gas, the condensation of acid vapor on the heated pipe wall can be avoided, and the generation rate of sulfur trioxide can be controlled, and the valve will be more effective. To

The installation position of the ventilation butterfly valve varies according to the design of the pipeline, such as horizontal, vertical and angled. Generally, vertical pipe installation of the ventilation butterfly valve has a better effect and is not easy to accumulate dust, followed by horizontal pipes, and has the worst effect at angles. The turning points on both sides of the valve inlet and outlet are most likely to form drift and ash blockage, and the valve operating torque will increase.

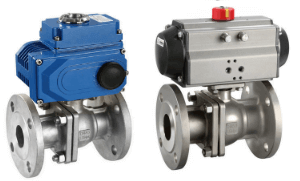

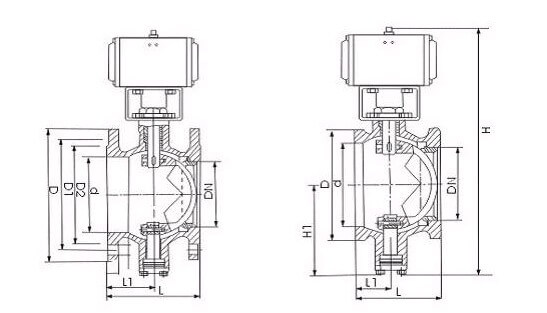

Related Products: Electric Ventilation Butterfly Valve Pneumatic Ventilation Butterfly Valve

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Features and structure drawings of flange butterfly valve;

electric hard seal butterfly valve vs electric soft seal butterfly valve;

Vulcanized vs soft seated/back-up butterfly valve;

Process design of check valve(

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.