Knife gate valve is suitable for viscous particles, often used in beverage, paper-making, pulp industry, industrial sewage, urban sewage treatment, chemical plants, bulk material transportation, fly ash treatment industries; DN50 to D1800, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, ABS, BV, Standards: EN 593, MSS SP-81

FEEDBACK

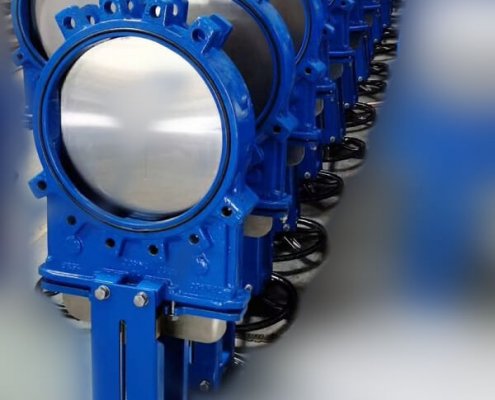

Knife Gate valve (TH-PZV)

The opening and closing part of the knife gate valve is the knife /gate, and the movement direction of the gate is perpendicular to the direction of the fluid. The manual knife gate valve can only be fully opened and fully closed, and cannot be adjusted or throttled. The gate has two sealing surfaces, The two sealing surfaces of the most commonly used mode gate valve form a wedge, and the wedge angle varies with valve parameters, usually 50. The gate of the wedge knife gate valve can be made into a whole, called a rigid gate; it can also be made A gate that can produce a small amount of deformation to improve its process characteristics and make up for the deviation of the angle of the sealing surface during the processing.This kind of gate is called an elastic gate.

When the knife gate valve is closed, the sealing surface can only rely on the medium pressure to seal, that is, rely on the medium pressure to press the sealing surface of the gate to the valve seat on the other side to ensure the sealing of the sealing surface, which is self-sealing. The gate valve adopts forced sealing, that is, when the valve is closed, the gate must be forced to press against the valve seat by external force to ensure the sealing performance of the sealing surface

Area of application

Knife gate valve is suitable for viscous particles, often used in beverage, paper-making, pulp industry, industrial sewage, urban sewage treatment, chemical plants, bulk material transportation, fly ash treatment industries;

Technical Parameters /Properties of Knife Gate Valve:

| Type: | Wafer, lug, double flanged |

|---|---|

| Size & Connections: | DN50 to D1800 |

| Medium: | Oil, Mud, material, viscous, granular fluid |

| Materials: | Cast Iron / Ductile Iron/ Carbon Steel / Stainless steel / Alu Bronze |

| Pressure Rating: | PN10, PN16, 150LB, |

| Temperature: | -30°C to 200°C |

| Seat/Lining: | Resilient seated NBR/EPDM/VITON, metal seated. |

| Certificates & Approvals: | DNV-GL, Lloyds, DNV, ABS, BV Type Approval 3.1 & 3.2 Cert (on request) |

Standards

- Design and Manufacture Conform to EN 593、MSS SP-81

- Flange dimensions Conform to EN 1092-2, ANSI B16.5

- Face to Face dimensions Conform to TAPPI TIS405.8

- Topwork’s dimensions Conform to ISO5211

- Testing Conform to API598、MSS SP-81

Material of Parts

| Part name | Material |

|---|---|

| Body | GG25/GGG40, WCB, CF3,CFCM,CF8,CF8M, |

| Seat | NBR/EPDM/VITON |

| Disc | SS201/304/316, 2Cr13 |

| Packing | PTFE /Kelvar |

| Gland | GG25/GGG40,WCB, SS |

| Stem Nut | QAL9-4 |

| Stem | 2Cr13 |

| Yoke | Q235A |

| Support | Carbon Steel |

| Hand wheel | HT250 |

| Bolts/Nuts | A193 B7 /A194 2H |

| Bearing | Bearing Steel |

| Cap | Steel |

Actuation

- Hand lever

- Worm-gear/hand-wheel

- Electric-actuator

- Pneumatic-actuator

- Hydraulic-actuator

Types of knife gate valves:

- Knife gate valve driving mode: manual, electric, pneumatic, hydraulic, bevel gear, electro-hydraulic and pneumatic-hydraulic driving modes.

- Knife gate valve shape: two kinds of rising stemand non-rising stem.

- Knife gate valve material: cast iron, cast steel, carbon steel, stainless steel, fluorine lining, etc.

- Knife gate valve seal: hard seal, soft seal, single-sided seal, double-sided seal and other materials.

The development of knife gate valves in China has gone through a short period of 20 years, and its use has expanded from ordinary fields to a wider range of industries. Coal preparation, gangue discharge and slag discharge from mines and power plants. It has developed into urban sewage treatment, and has developed from general industrial pipelines to professional pipeline systems such as food, sanitation, and medicine. The ultra-thin knife gate valve completely solves the large flow resistance of ordinary gate valves, flat gate valves, ball valves, globe valves, regulating valves, butterfly valves and other valves with its advantages of small size, small flow resistance, light weight, easy installation, and easy disassembly. , Heavy weight, difficult installation, large area and other difficult problems. After the emergence of knife gate valves, a large number of general shut-off valves and regulating valves have been replaced.

Work performance and installation of knife gate valve

Knife gate valve has the advantages of simple and compact structure, reasonable design, light material saving, reliable sealing, light and flexible operation, small size, smooth passage, small flow resistance, light weight, easy installation, easy disassembly, etc. It can work at a working pressure of 1.0MPa- 2.5MPa, normal work under the operating temperature of -29-650℃. The gate of the knife gate valve has a shearing function, which can scrape off the adhesion on the sealing surface and automatically remove the debris. The stainless steel gate can prevent the seal leakage caused by corrosion.

Installation and use of knife gate valve

- Before installation, check the valve cavity and sealing surface and other parts, and no dirt or sand particles are allowed to adhere;

- The bolts of each connection part shall be evenly tightened;

- Check that the packing parts are required to be pressed tightly, not only to ensure the tightness of the packing, but also to ensure the flexible opening of the gate;

- Before installing the valve, the user must check the valve model, connection size and pay attention to the flow direction of the medium to ensure consistency with the valve requirements;

- When installing the valve, the user must reserve the necessary space for the valve drive;

- The wiring of the drive device must be carried out according to the wiring diagram;

- Knife gate valves must be maintained regularly, and no collision or squeezing is allowed to avoid affecting the seal.

Knife gate valve types: single clamp type knife gate valve, single clamp type slurry gate valve, single clamp type knife gate valve, Knife type mud gate valve, knife type slag discharge gate valve, single clamp type slurry gate valve.

Knife Gate valve features

Structural characteristics of knife gate valve

- The lift-ablegate sealing surface can scrape off the adhesive on the gate and automatically remove debris.

- Stainless steel gate can prevent seal leakage caused by corrosion.

- The overall stainless steel material can prevent corrosion damage.

- The short structure length can save raw materials and installation space, and also effectively support the strength of the pipeline.

- TheScientific upper seal stuffing box design makes the upper seal safe, effective and durable.

- The Triangular bracket saves raw materials and ensures the required mechanical properties.

- The guide block on the valve body makes the gate move correctly. The squeeze block ensures effective sealing of the gate.

- The design of the body stiffener improves the strength of the valve body.

- Stainless steel valve stem is durable, and the double-headed screw can be opened and closed more quickly.

- The driving methodcan be selected arbitrarily.

- The V-type gate can be used as a regulating valve.

Related types of valves:

We can also produce gate valve, check valve, globe valve, and ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D,

tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved. tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com