Reasons and fixing for Leakage of the seat of the metal seated Gate Valve

The metal seated gate valve is well used in high temperature and high pressure media, but it also requires high quality due to the particularity of the working conditions, and the sealing problem that makes users most concerned about. What are the main reasons for leakage on the sealing surface? What measures can we take? The sealing

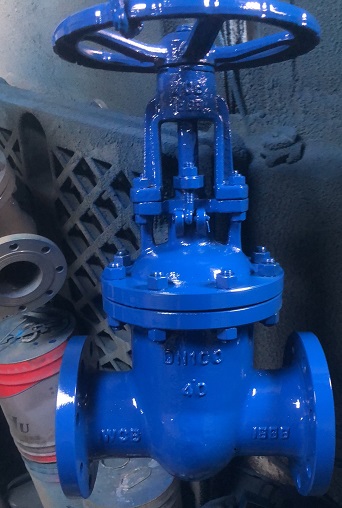

PN40-DN100 cast steel WCB gate valve photo

surface of the gate valve is the core part of the valve. There are four ways of leaking, namely, leakage of the sealing surface, leakage of the joint of the sealing ring, leakage caused by the falling of the closure and leakage of foreign objects embedded between the sealing surfaces. Today we mainly take a look at the leakage causes and solutions of the sealing surface.

1. The sealing surface of the metal sealing gate valve is unevenly ground and cannot form a tight line. Therefore, when the manufacturer grinds the sealing surface, grinding tools, abrasives, emery cloth, sandpaper and other objects should use reasonable grinding methods to be accurate. After grinding, they should be colored and checked. The sealing surface should be free of defects such as indentation, cracks, and scratches.

2. The top center of the connection between the valve stem and the closing part is suspended, incorrect or worn. In production, it is necessary to pay attention to the connection between the valve stem and the closure piece to meet the requirements. The top center should have a certain movable clearance, especially the axial clearance between the valve stem table and the closing part is not less than 2mm.

3. The valve stem is tortuous or the equipment is not right, which makes the closing part tilted or misaligned. If it is because of this situation, it is necessary to straighten and adjust in time to ensure that the valve stem, valve stem nut, closing parts, and valve seat are on a common axis after adjustment.

4. Unscientific selection of raw materials for the sealing surface or unsuitable working conditions of valve selection, resulting in corrosion, erosion and abrasion of the sealing surface. When selecting a valve or replacing the sealing surface, it should meet the working conditions.

5. Surfacing and heat treatment are not operated in accordance with the regulations. The defects such as wear due to low hardness, corrosion due to burning of alloy elements, and cracks due to excessive internal stress will also cause leakage of the sealing surface of the metal sealing gate valve. During the production process of the manufacturer, pay attention to the surfacing welding and heat treatment skills to meet the technical requirements of the compliance procedures and standards. After the sealing surface is processed, the inspection should be carried out to eliminate any shortcomings that affect the use.

6. The sealing surface is not tightly closed or the crevices appearing due to cold shrinkage after sealing, causing a phenomenon of eclipse. For high-temperature valves, some of the slits that show cold shrinkage after being closed should be closed again at a certain time after being closed to be used as a shut-off valve.

7. The metal sealing gate valve has reached the fully enclosed position and continues to exert excessive sealing force, including inaccurate use of long lever operation, and the sealing surface is crushed and squeezed. Therefore, whether it is a metal-sealed gate valve or not, all valves must be opened and closed in accordance with the operating specifications and signs given by the manufacturer. Strictly implement one-person operation or two-person operation according to the size of the valve handwheel, and whether levers within 500mm are allowed.

8. Excessive wear of the sealing surface causes the sealing pair to fail to fit perfectly. To prevent this situation, it should be adjusted in time, and the sealing surface that cannot be adjusted should be replaced.

The quality assurance of the metal seated gate valve is deeply related to the unevenness of the valve manufacturing quality, the quality of the working conditions, the quality of the operation, and the quality of maintenance. Only strict design and production of each link can ensure the safe operation of the valve without problems.

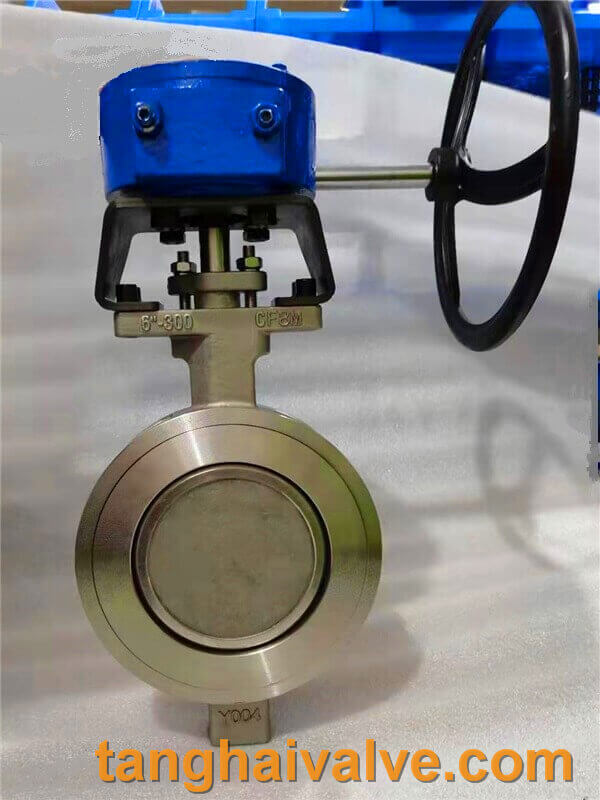

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Reasons and solutions for leakage of valve sealing surface

Properties of Fixed ball valve

Application of low temperature butterfly valve

The correct operation method of manual valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.