What is the material of the main parts of the butterfly valve?-(1)

Selection of butterfly valve parts materials:

There are many materials for manufacturing butterfly valves, including ferrous and non-ferrous metals and their

16 U-type-flange-butterfly-vlave-body

alloys of different brands, and various non-metallic materials. The materials for manufacturing valve parts should be selected based on the following factors:

1. Pressure, temperature and characteristics of working medium.

2. The force of the part and its function in the valve structure.

3. It has better manufacturability.

4. If the above conditions are met, there must be a lower cost.

The material of the valve body, bonnet and disc (disc) The body, bonnet and gate (disc) are one of the main parts of the valve, which directly bear the pressure of the medium, and the material used must meet the “pressure and temperature rating of the valve” Provisions.

Commonly used material types for butterfly valves:

1. Gray cast iron: Gray cast iron is suitable for water, steam, air, gas, oil and other media with a nominal pressure of PN≤1.0MPa and a temperature of -10℃~200℃. The commonly used grades of gray cast iron are: HT200, HT250, HT300, HT350.

2. Malleable cast iron: Suitable for water, steam, air and oil media with a nominal pressure

17 center-line-butterfly-valve-plate-disc-parts-4

of PN≤2.5MPa and a temperature of -30~300℃. Commonly used grades are: KTH300-06, KTH330-08, KTH350-10.

3. Ductile iron: suitable for water, steam, air and oil with PN≤4.0MPa and temperature of -30~350℃. Commonly used grades are: QT400-15, QT450-10, QT500-7. In view of the current level of domestic technology, the plants are uneven, and users are often not easy to inspect. According to experience, it is recommended that PN≤2.5MPa, and the valve should be made of steel for safety.

4. Acid-resistant high-silicon ductile iron: suitable for corrosive media with nominal pressure PN≤0.25MPa and temperature below 120℃.

5. Carbon steel: suitable for water, steam, air, hydrogen, ammonia, nitrogen and petroleum products with a nominal pressure of PN≤32.0MPa and a temperature of -30~425℃. Commonly used grades are WC1, WCB, ZG25 and high-quality steel 20, 25, 30 and low-alloy structural steel 16Mn. Six, copper alloy: suitable for water, sea water, oxygen, air, oil and other media with PN ≤ 2.5MPa, and steam media with a temperature of -40 to 250 ℃, commonly used brands are ZGnSn10Zn2 (tin bronze), H62, Hpb59-1 (Brass), QAZ19-2, QA19-4 (aluminum bronze).

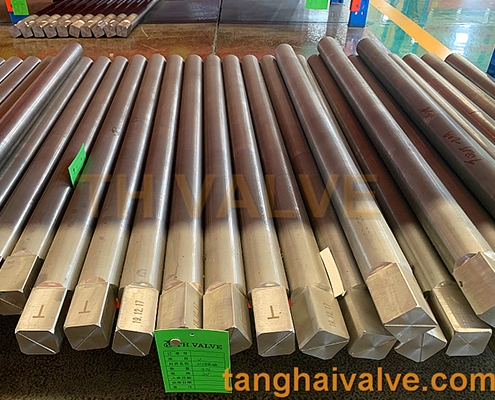

18 buttefly-valve-stem-shaft-parts-1

7. High temperature steel: suitable for steam and petroleum products with nominal pressure PN≤17.0MPA and temperature≤570℃. Commonly used grades are ZGCr5Mo, 1Cr5M0. ZG20CrMoV, ZG15Gr1Mo1V, 12CrMoV, WC6, WC9, etc. The specific selection must be in accordance with the valve pressure and temperature specifications. 8. Low temperature steel, suitable for nominal pressure PN≤6.4Mpa, temperature≥—196℃ ethylene, propylene, liquid natural gas, liquid nitrogen and other media, commonly used grades) ZG1Cr18Ni9, 0Cr18Ni9, 1Cr18Ni9Ti, ZG0Cr18Ni9.

9. Stainless acid-resistant steel, suitable for nitric acid, acetic acid and other media with nominal pressure PN≤6.4Mpa and temperature≤200℃. Commonly used grades are ZG0Cr18Ni9Ti, ZG0Cr18Ni10<nitric acid>, ZG0Cr18Ni12Mo2Ti, ZG1Cr18Ni12Mo2Ti<acid and urea>.

tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.