With the progress and continuous reform of the times, my country’s valve products have also been innovated with the change of the times. At present, in the valve market where environmental protection and safety are increasingly

ductile iron, DI, butterfly valve, manufacturer, center line, TH valve

demanded, the use of automatic control devices such as electric valves and pneumatic valves is gradually becoming impossible Optional. The use of self-control valves is more energy-saving, safer and more reliable. Compared with the traditional manual valve, the movement speed is faster than the ordinary valve, which not only reduces the manpower, but also greatly improves the work efficiency.

Compared with the pneumatic valve, the electric valve has a simple structure and reliable operation, and its power source (power source or air source) is easy to solve for the remote operation point. The disadvantage is that the price is higher and the explosion-proof requirements are also higher. When selecting, comprehensive consideration should be given to factors such as the

electric ball valve

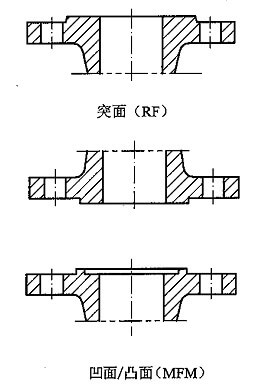

availability, price and control requirements of the power source. The selection of the valve generally first confirm the valve material, valve diameter, medium type, pipeline pressure, connection mode, control mode, medium temperature etc.

Electric valve selection: When electric valve is selected (the control mode of electric actuator is generally divided into on-off type and regulating type), in addition to the basic valve body diameter, pressure, material and other requirements, the following parameters should be provided:

1. Power supply parameters (including voltage, number of phases and frequency);

pneumatic ball valve

2. Running time and form of electric actuator;

3. Whether explosion-proof and explosion-proof grade are required;

4. Atmospheric protection level;

5. Overload protection requirements, such as over travel protection, over torque protection, etc.;

6. Local operation requirements, such as whether to bring a local operation handwheel;

7. Operation instruction requirements.

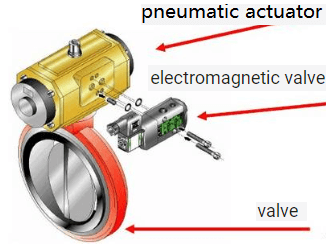

Pneumatic valve selection: When selecting pneumatic valves (the operating principle of pneumatic actuators can be divided into single-acting and double-acting), in addition to determining specific parameters such as valve body diameter, pressure, and material, the following parameters should also be provided:

1. Air source parameters (including air source pressure range, whether to bring your own gas storage tank, etc.)

2. Running time and form of pneumatic actuator

3. Whether explosion-proof and explosion-proof grade are required;

4. Atmospheric protection level;

5. Overload protection requirements, such as over travel protection, over torque protection, etc.;

6. Local operation requirements, such as whether to bring a local operation handwheel;

7. Operation instruction requirements.

As the level of industrial automation requirements has increased significantly, the demand for electric (pneumatic) valves is also increasing, and the control requirements for electric (pneumatic) valves have become more and more detailed and complex. For the correct selection of electric (pneumatic) valves, it not only involves the correct use of the product, but also may affect the safety of the entire pipeline system. Users should understand and understand the relevant selection knowledge.

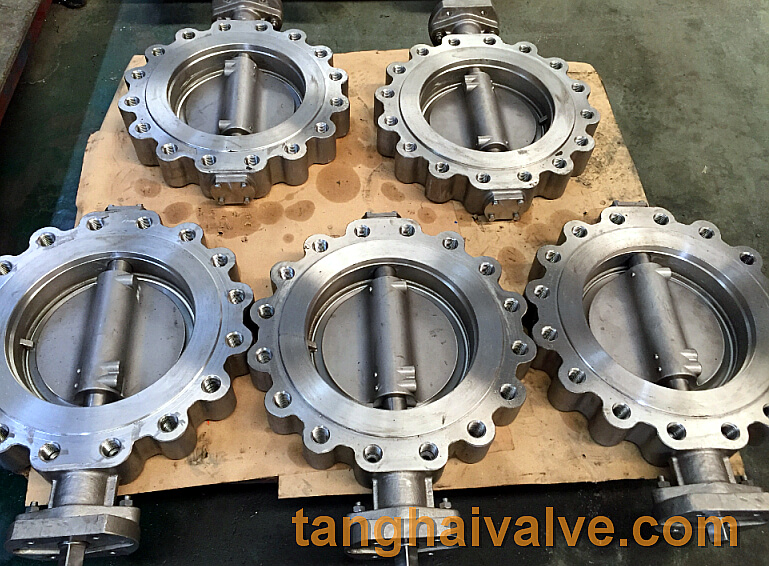

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Applicable occasions and operation method of ball valve;

working principle of electric globe valve;

Notes on selection and installation of butterfly valve;

Description of electric valve connection

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.