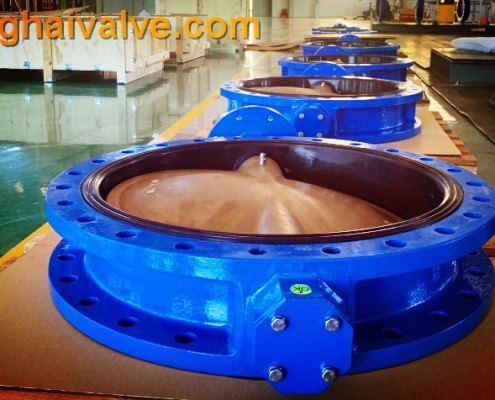

Structure of Triple Eccentric Metal seated Butterfly Valve (Picture)

Butterfly valves can be divided into soft-sealed butterfly valves and metal seated butterfly valves according to the sealing form. This article mainly analyzes the structure of the triple eccentric metal seated butterfly valve. Metal hard seal butterfly valves are usually used in some high temperature and high pressure environments. They are mainly composed of valve body, butterfly plate, valve shaft, valve seat, butterfly plate sealing ring, shaft sleeve, self-lubricating bearing, driving device and so on.

D943H-16C-metal seated stainless steel electric triple offset butterfly valve

The triple eccentric metal hard seal butterfly valve is a high-performance butterfly valve. It drives the rotation of the valve shaft through various driving devices, and the valve shaft drives the butterfly plate to rotate within the range of 0-90° in the valve body passage to achieve the valve opening and closing. The purpose is to realize the control of the medium flowing in the pipeline. Because of its super high performance, the triple eccentric metal hard seal butterfly valve can be widely used in the pipelines of generators, steam, hot and cold air, chemical smelting engineering, power generation, environmental protection, etc. The applicable media include various corrosive and non-corrosive fluid media. .

Structure diagram of triple eccentric metal seated butterfly valve

Insert “154-1 Picture”

Structural features of triple eccentric metal seated butterfly valve

①Unique and novel three-way eccentric design, frictionless transmission between sealing surfaces, greatly prolonged valve life.

②The elastic seal is produced by the torque, which improves the sealing performance of the valve.

③The wedge-shaped design allows the valve to be closed tighter and tighter, realizing automatic sealing, and the sealing surfaces directly compensate each other to achieve zero leakage.

④The drive mode of the valve can be selected according to the needs of customers, such as equipped with pneumatic and electric devices.

⑤ Only need to change the material of the parts, the valve can be applied to different media, and it can also be lining anti-corrosion (lining F46, GXPP, PO, etc.).

⑥The sealing ring is made of stainless steel, and it has the advantages of metal hard seal and elastic seal. It can achieve good sealing performance regardless of low temperature environment or high temperature working conditions.

If you want to know more about the triple eccentric metal seated butterfly valve, please pay more attention to the official website of “Tanghai Valve”. If you have any valve requirements in this area, you are also welcome to inquire.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of triple eccentric butterfly valve:

Related news/knowledge:

What is a triple eccentric metal seated butterfly valve

Application of double eccentric butterfly valve and triple eccentric butterfly valve

Precautions for the use of triple eccentric metal seated butterfly valve

What are the characteristics of the hard seal butterfly valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.