Classification and introduction of pipe thread-(3)

Sealing pipe thread (R)

The basic dimensions and tolerances of inch sealing pipe threads

Cooperate way

There are two matching methods for inch seal pipe threads: cylindrical internal thread and conical external thread form a “column/cone” fit; conical internal thread and conical external threa

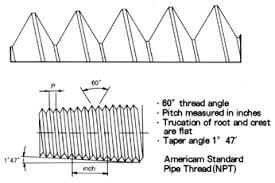

NPT thread picture

d form a “cone/cone” fit.

European countries mainly use “column/cone” matching threads; countries outside Europe mainly use “cone/cone” matching threads. The inspection gauges for the two types of threads are somewhat different; the current ISO inch seal pipe thread gauge standard (ISO 7- 2:2000) is designed according to the “column/cone” coordination system.

mark

The complete mark of inch seal pipe thread is composed of thread feature code, thread size code and rotation direction code.

The characteristic code of inch sealed cylindrical internal thread is: RP;

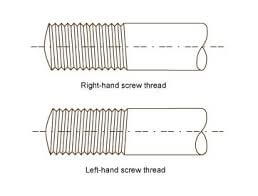

left &right hand thread

The characteristic code of the inch sealing cone internal thread is: RC;

The characteristic code of the inch sealing cone external thread is: R1 (used with the inch sealing cylindrical internal thread);

R2 (used in conjunction with inch sealing cone internal thread);

The rotation code of the left-hand thread is LH; the rotation code of the right-hand thread is omitted and not marked.

For sealing pipe threads, use RP/R1 and RC/R2 to indicate “column/cone” and “cone/cone” thread pairs respectively.

Unsealed pipe thread

The basic size and limit deviation of the imperial unsealed pipe

mark:

The complete mark of inch unsealed pipe thread is composed of thread feature code, thread size code, pitch diameter tolerance grade code and rotation direction code.

The characteristic code of inch unsealed cylindrical thread is: G

For inch non-sealed cylindrical internal threads, the codes for the tolerance grades of the median diameter are omitted and not marked; while the codes for the pitch diameter and metric grades of the inch non-sealed cylindrical external threads are A and B respectively.

When indicating the thread pair of the inch unsealed pipe thread, only the marking code of the external thread is marked.

Example:

Right-handed, non-sealed cylindrical female thread with size code 2: G2

Class A with size code 3, right-handed, unsealed cylindrical external thread: G3A

Grade B with size code 4, left-handed, unsealed cylindrical external thread: G4 B-LH

Thread pair consisting of a right-handed, non-sealed cylindrical internal thread and a grade A cylindrical external thread with a dimension code of 2: G2A

The inner thread is processed by pipe thread taps, and the outer thread has die.

Note: 2, 3, 4 above are code names, not inch sizes, don’t confuse

other

Conversion of 55° tapered pipe thread

55° tapered pipe thread means that the thread angle is 55° and the thread has a taper of 1:16. This series of thread is widely used in the world, and its code is different from country to country.

China UK France Japan iso

Code ZG R (outside) G PT R

R (external thread) Rc (internal) R R Rc

Conversion of 60° Conical Pipe Thread

The 60° tapered pipe thread refers to a pipe thread with a tooth profile angle of 60° and a thread taper of 1:16. This series of threads is used in the machine tool industry in my country, the United States and the former Soviet Union. Its code name was previously designated as K in our country, and later designated as Z, now it is changed to NPT.

tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.