7 types of flange sealing surface: FF, RF, M, FM, T, G, RTJ

Flanged butterfly valve has a flange on the valve, and bolts are used to connect the flanges at both ends of the valve to the pipe flange. Do you know all the 7 types of flange sealing surfaces? FF, RF, MF, M, T, G, RTJ

The flange sealing surface basically has:

Full plane: FF

Raised face: RF

Concave/female: FM

Convex/Male: M

Tenon: T

Groove surface: G

Ring connection surface RTJ (RJ) types, according to the different working conditions, medium, pressure, specifications, temperature, etc., so the selected types are not the same. Let’s get to know the types of these flange sealing surfaces together!

FF-full plane:

Flat Face Full Face type sealing surface is completely flat, suitable for occasions where the pressure is not high and the medium is non-toxic.

flange FF

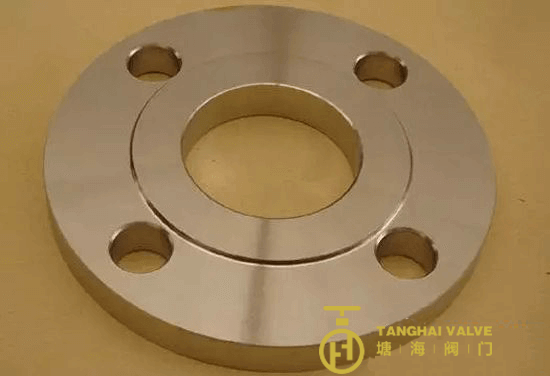

RF-raised face:

The Raised Face type of sealing surface is the most widely used among several types, and the most commonly used one. The international standards, European system and domestic standards are all fixed heights, but in the American standard flange, it should be noted that the height of high pressure will increase the sealing surface. There are also many types of gaskets used. Gaskets suitable for raised face sealing surface flanges include various non-metallic flat gaskets, coated gaskets; metal-wrapped gaskets; spiral wound gaskets (including outer ring or inner and outer ring).

flange RF

Convex/Male: M

Concave /female: FM

The two types of sealing surfaces, Male Face and Female Face, are a pair, one female and one male. They must be used together. They are easy to align and prevent the gasket from being extruded. Suitable for occasions with higher pressure.

The suitable sealing gaskets for the concave-convex sealing surface include: various non-metallic flat gaskets and coated gaskets; metal-clad gaskets; basic type or winding stopper with inner ring, etc.

T-tenon

G-groove surface

Tongue Face and Groove Face are similar to the concave-convex surface. They are also a male and female matched sealing surface type, and they are also used in pairs. The gasket is located in the annular groove and is restricted by the metal walls on both sides. It can prevent the gasket from being compressed and deformed and squeezed into the pipeline. Since the gasket is not in direct contact with the fluid medium in the pipe, it is less eroded or corroded by the fluid medium, so it can be used for high pressure, flammable, explosive, and toxic mediums that require strict sealing. This kind of sealing surface gasket has good installation and neutrality, but it is difficult to process the sealing surface. It is easy to damage the sealing surface when replacing the gasket, and the flange must be separated in the axial direction during installation and disassembly. Therefore, consideration should be given to the pipeline design. It is possible to separate the flange in the axial direction.

Suitable gaskets for the sealing surface of the tongue and groove surface include: various metal and non-metal flat gaskets, metal-clad gaskets and basic spiral wound gaskets.

flange TG-

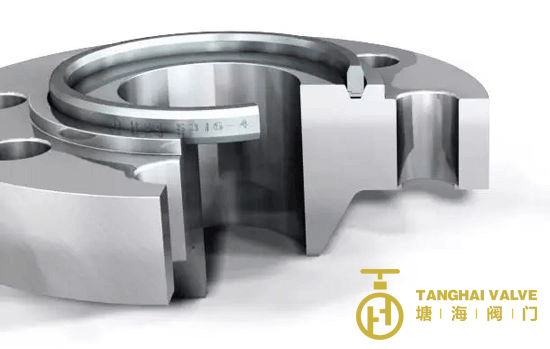

RTJ(RJ)-Ring connection surface

The flange of the Ring Joint Face seal is also a narrow-face flange, and an annular trapezoidal groove is opened on the flange surface as the flange sealing surface, which is the same as the tongue-and-groove flange. The flange must be separated in the axial direction during installation and disassembly. Therefore, the possibility of separating the flange in the axial direction should be considered in the pipeline design.

The sealing surface is specially designed to cooperate with solid metal gaskets processed into octagonal or elliptical shapes from metal materials to achieve a sealed connection. Since the metal ring gasket can be based on the inherent characteristics of various metals, the sealing performance of this sealing surface is good, and the installation requirements are not too strict. It is suitable for high temperature and high pressure working conditions, but the processing accuracy of the sealing surface is relatively high. (According to the Pipe Fittings, Pumps and Valves Alliance)

flange-RTJ-RJ-

flange-RTJ-RJ-02

tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.