Design standards and materials for single door check valves

Design Standards for Single Door Check Valves

Single door check valves are designed and manufactured according to various international standards to ensure quality, reliability, and compatibility. Some of the common standards include:

API 594: Covers the requirements for check valves, including design, manufacturing, testing, and inspection.

ASME B16.34: Provides standards for pressure-temperature ratings, dimensions, and materials for valves.

ISO 5752: Standardizes face-to-face and end-to-end dimensions of valves.

BS 1868: Specifies requirements for check valves for petroleum, petrochemical, and allied industries.

DIN 3202: Specifies face-to-face dimensions for valves used in piping systems.

Common Materials Used in Single Door Check Valves

The selection of materials for single door check valves depends on the application, including the type of fluid, operating temperature, and pressure. Common materials include:

Body Materials:

Stainless Steel (e.g., 304, 316): Offers excellent corrosion resistance and strength, suitable for a wide range of applications, including aggressive fluids.

Carbon Steel: Provides good strength and durability, commonly used in water, oil, and gas

applications.

Ductile Iron: Combines good strength and impact resistance, often used in water and wastewater applications.

Bronze: Good corrosion resistance, commonly used in marine and potable water applications.

Stainless Steel: For applications requiring high corrosion resistance.

Carbon Steel: Used for general-purpose applications.

Bronze: Commonly used in applications involving seawater or drinking water.

Composite Materials: Such as reinforced plastics for lightweight and corrosion-resistant applications.

Seat Materials:

Metal Seats (e.g., stainless steel, bronze): Durable and can withstand high temperatures and pressures.

Soft Seats (e.g., EPDM, NBR): Provide better sealing and are used in applications where tight shutoff is required, typically at lower temperatures and pressures.

Spring Materials (if applicable):

Stainless Steel: Commonly used for springs due to its good corrosion resistance and mechanical properties.

Inconel: For high-temperature applications requiring superior strength and corrosion resistance.

Considerations for Material Selection

Corrosion Resistance: Ensure the material can withstand the fluid’s chemical properties.

Temperature and Pressure: The material must be able to handle the operating conditions without degrading.

Mechanical Properties: The material should have the necessary strength and durability for the application.

Regulatory Compliance: Ensure materials meet any regulatory or industry standards required for the application.

By selecting appropriate materials and adhering to design standards, single door check valves can provide reliable and long-lasting performance in a variety of industrial applications.

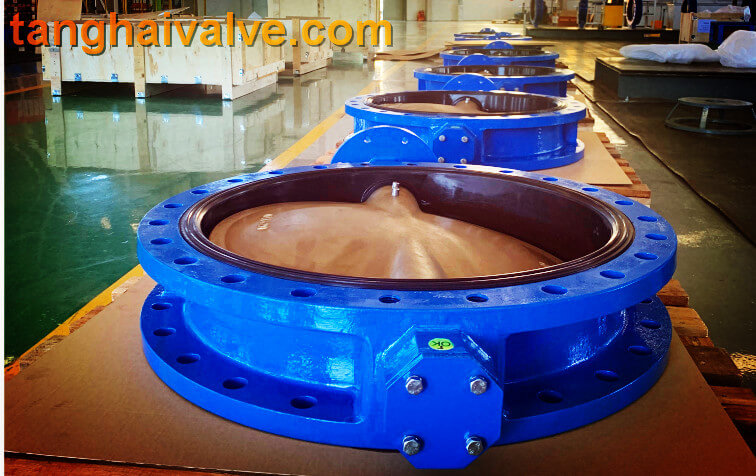

Tianjin Tanghai Valve Co., Ltd. is a professional marine valve manufacturer, including butterfly valve, check valve, gate /Knife gate valve. We have certificates: CE, ISO, BV, DNV foundry and products approval. Now we have our own independent R & D, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services. Below is our wafer butterfly valve of marine valves,if you need to check more information, please click here: https://www.tanghaivalve.com/wafer-type-butterfly-valve-th-btv-aw/

Please contact us if you need more support, please contact us freely: info@tanghaivalve.com.We are committed to “Build a top valve enterprise; Be a reliable partner!”Friends from all over the world are welcome to visit us for evaluation, guidance, and orders!

Selection Considerations:

Selection Considerations: Usage:

Usage:

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.