What is a fluorine-lined valve? How to extend the service life of it?

Fluorine-lined valves are made by using PTFE resin (or profile processed) to be molded (or inlaid) on the inner wall of the steel or iron valve pressure part or the outer surface of the valve inner part, and use its The unique performance of the anti-corrosive medium valve is made into various types of valves and pressure vessels.

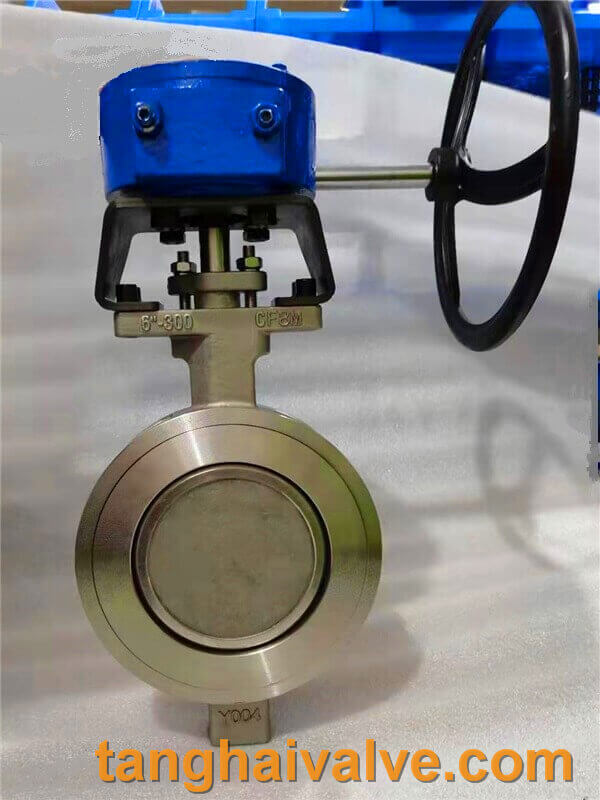

Fluorine lined butterfly valve-PTFE-WAFER (10)

Among anti-corrosion materials, polytetrafluoroethylene has incomparable excellent performance. In addition to molten metal, elemental fluorine and aromatic hydrocarbons, it is used in various concentrations of hydrochloric acid, sulfuric acid, nitric acid, aqua regia, organic acids, strong oxidants, and concentrated , Alternate dilute acid, alternate alkali, and various organic agents are all reacting spontaneously. The inner wall of the valve is lined with polytetrafluoroethylene, which not only overcomes the shortcomings of low strength of polytetrafluoroethylene material, but also solves the corrosion resistance of the valve theme material. Poor performance and high cost. In addition to its excellent chemical stability, PTFE has good antifouling, anti-sticking properties, extremely low dynamic and static friction coefficients, and good anti-friction and wet performance. Use it as a valve opening and closing sealing pair, and it is necessary to reduce the sealing surface The friction force between the valve and the operating torque of the valve is reduced, and the service life of the product is increased. The scope of its application can also be extended to the food and pharmaceutical industries.

Fluorine-lined valves are also known as anti-corrosion valves. They are often exposed to harsh working conditions. They are not toxic and harmful chemicals, or are very corrosive. Various acids and alkalis or organic solvents. Improper use will cause major economic losses and serious problems. as a result of. Correct use and maintenance of the valve can prolong the service life of the fluorine-lined valve. What details can be done to effectively protect it?

1. Before use, carefully read the fluorine-lined valve instruction manual.

2. Use according to the pressure, temperature, and use medium specified on the nameplate or in the manual.

3. When using, prevent the fluorine-lined valve from generating excessive pipeline stress due to temperature changes, minimize temperature changes, and add U-shaped expansion joints before and after the valve.

4. It is forbidden to use levers to open and close the fluorine-lined valve. Pay attention to the opening and closing indication position and limit device of the fluorine-lined valve. After opening and closing are in place, do not forcefully close it to avoid premature damage to the fluorine plastic sealing surface.

5. For some media that are unstable and easy to decompose (such as the decomposition of some media will cause volume expansion and abnormal pressure increase in working conditions), which will cause valve damage or leakage, measures should be taken to eliminate or limit the factors that cause unstable media to decompose . When selecting the valve type, the fluorine-lined valve with automatic pressure relief device should be selected in consideration of the changes in working conditions that may be caused by the unstable and easy decomposition of the medium.

6. For fluorine-lined valves on pipelines with toxic, flammable, explosive, and highly corrosive media, it is strictly forbidden to replace the packing under pressure. Although the fluorine-lined valve is designed to have an upper sealing function, it is not recommended to replace the packing under pressure.

7. For pipelines with spontaneous flammable media, measures must be taken to ensure that the ambient temperature and working condition temperature do not exceed the spontaneous ignition point of the media to prevent the danger caused by sunlight or external fire.

Applicable medium: various concentrations of acid-base salts and certain organic solvents.

Features: It is the most ideal anti-corrosion material in the world at present, and it has been widely used in the lining of large-scale rotary forming equipment and pipe fittings.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of PTFE butterfly valve:

Related news/knowledge:

Ways to Extend the Service Life of Valves

The difference between fluorine-lined butterfly valve and metal butterfly valve

Classification and selection of fluorine-lined valves

electric fluorine-lined butterfly valve vs electric metal seated butterfly valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.