Pneumatic ball valve model preparation method

Pneumatic ball valve model preparation method/code name establishment in China.

With the rapid development of my country’s industrial modernization, the use of valves is also increasing. Pneumatic ball valves have the advantages of fast opening and closing speed, and not only can switch and cut off, but also control flow, etc., and become the most widely used valve type. one! However, due to the wide variety of pneumatic ball valves, including the use of pressure, temperature and control methods, the corresponding ball valve models are also different. In order to avoid errors in the selection of the user, and to ensure that the pneumatic ball valve can be used normally, more instruments Self-Control Valve Company hereby provides instructions for the preparation of pneumatic ball valve models for everyone to understand and recognize!

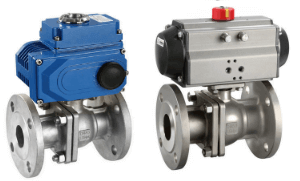

Pneumatic electric high platform ball valve

Pneumatic ball valve model editing instructions are mainly from the increase of additional conditions of the pneumatic ball valve, the selection of the drive mode, the difference of the connection form, the change of the structure form, the type of sealing material, the level of valve pressure and the material of the valve body, etc. to facilitate the explanation, hope It is helpful to the majority of users.

Pneumatic ball valve model representation method:

Ball valve additional code: V means the valve core has a V-shaped structure, D means low temperature, B means heat preservation, P means eccentric structure, U, S and DY mostly mean top-mounted type;

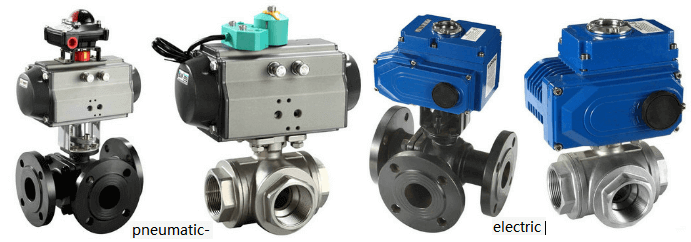

Ball valve name code: Q means ball valve; Ball valve drive code: 2 means electro-hydraulic, 3 means turbine, 6 means pneumatic, 7 means hydraulic, 9 means electric, manual without code;

Code of connection method: 1 means internal thread, 4 means flange type, 6 means welding, 7 means wafer type;

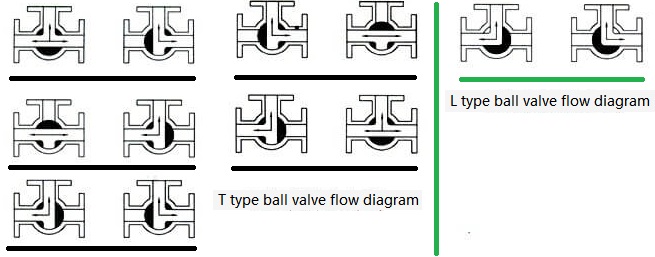

Structural type code: Floating type: 1 means straight-through runner, 2 means Y-type tee, 4 means L-type tee, 5 means T-type tee; Fixed type: 0 means hemispherical through, 6 means four-way runner, 7 Means straight-through flow to, 8 means L-type tee, 9 means Y-type tee;

Sealing material code: B babbitt alloy, F fluorine rubber, F46 lining fluorine, H stainless steel, J rubber lining, M Monel alloy, N nylon plastic, Monel P, Y cemented carbide, W valve body directly processed;

Pressure rating code: 16 means the pressure is 16 kg (1.6Mpa) and the maximum can reach 64Mpa; 150LB means the American standard pound pressure, and the maximum pressure rating can reach 2500LB (150LB=1.6MPA/300LB=2.5-4.0mpa/400LB=6.4 mpa/600LB=10mpa); 5K means Japanese pressure, maximum pressure is 63K; Valve body material code: A titanium and titanium alloy, C carbon steel, I chromium molybdenum steel, P18-8 series stainless steel, RMo2Ti series stainless steel, S plastic.

Pneumatic ball valve model editing instructions:

Q645F-16P Stainless steel pneumatic flange three-way ball valve

1. Q: represents the ball valve;

2. 6: It means that the transmission mode is pneumatic;

3. 4: The connection method is flange connection;

4. 5: The structure is a floating T-type tee;

5. F: The sealing material is fluorine rubber;

6. 16: Indicates that the nominal pressure is 1.6MPa;

7. P: indicates that the valve body is made of stainless steel.

More details for valve model establishment, you can visit another article: https://www.tanghaivalve.com/valve-model-establishment-and-meaning/

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.