Stainless steel valve material parameters and specific applications

The following are several stainless steel valve material parameters and specific applications:

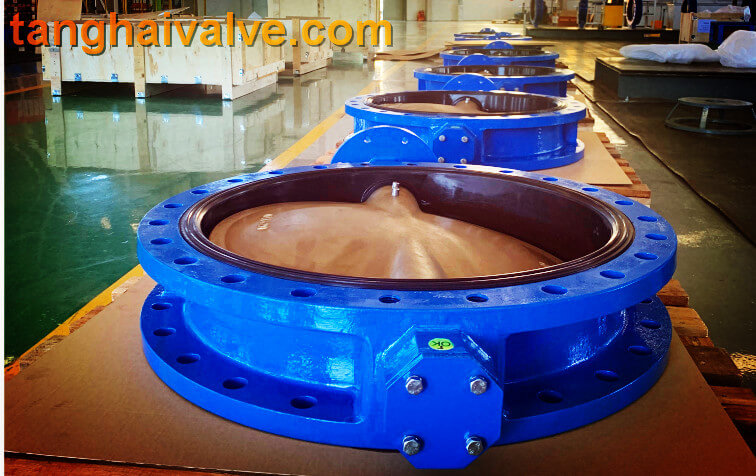

ductile iron, DI, butterfly valve, manufacturer, center line, TH valve

(1) Angle stroke includes ball valve, butterfly valve, plug valve, etc.

(2) Straight stroke includes gate valve, globe valve, angle seat valve, etc.

This classification method is divided according to the principle, function and structure. It is the most commonly used international and domestic classification method. General gate valve, cut-off

Valves, throttle valves, instrument valves, plunger valves, diaphragm valves, plug valves, ball valves, butterfly valves, check valves, pressure relief valves, safety valves, traps, regulators Valves, bottom valves, filters, drain valves, etc.

Because the valve has a wide range of uses, it also plays a great role. For example, in power plants, valves can control the operation of boilers and steam turbines; in petroleum and chemical production, valves also control the normal operation of all production equipment and technological processes. The same is true in other departments. Nevertheless, the comparison of valves with other products is often overlooked. For example: When installing machinery and equipment, people tend to focus on the main machinery and equipment, but ignore the valve. This will reduce the overall production efficiency or stop production, or cause various other accidents. Therefore, serious and responsible work must be carried out on the selection, installation and use of valves.

double-wing-check-valve-3

Electric drive valve is a commonly used drive valve. The drive device of this drive device form is usually called the valve electric device. The characteristics of the valve electric device are as follows: 1) Rapid opening and closing can greatly shorten the time required to open and close the valve; 2) It can greatly reduce the labor intensity of the operator, especially suitable for high-pressure, large-diameter valves; 3) Suitable for installation in locations that cannot be manually operated or difficult to access, easy to achieve remote control, and the installation height is not limited; 4 ) Conducive to the automation of the entire system; 5) Power is easier to obtain than air and liquid sources, and the laying and maintenance of its wires are much simpler than compressed air and hydraulic pipelines.

The disadvantage of the valve electric device is its complex structure, and it is more difficult to use it in wet places. When used in explosive media, explosion-proof measures are required. Valve electric devices can be divided into two categories: Z-type and Q-type according to the type of valve they drive. The output shaft of the Z-type valve electric

stainless steel ball valve (8)

device can rotate many times, which is suitable for driving gate valves, stop valves, diaphragm valves, etc.; the output shaft of the Q-type valve electric device can only rotate 90. , Suitable for driving plug valves, ball valves and butterfly valves. According to its protection type, there are ordinary type, explosion-proof type (represented by B), heat-resistant type (represented by R) and three-in-one type (ie outdoor, anti-corrosion, explosion-proof, represented by S).

The valve electric device is generally composed of a transmission mechanism (reducer), a motor, a stroke control mechanism, a torque limit mechanism, a manual-electric switching mechanism, and an opening indicator.

Pneumatic and hydraulic valves:

Pneumatic valves and hydraulics use a certain pressure of air, water or oil as the power source, and use the movement of cylinders (or hydraulic cylinders) and pistons to drive the valves. Generally, the pneumatic air pressure is less than 0.8MPa, and the hydraulic water pressure or The oil pressure is 2.5MPa~25MPa. For example, it is used to drive a diaphragm valve; the rotary gas and liquid drive device is used to drive a ball valve, a butterfly valve or a plug valve. The hydraulic device has a large driving force and is suitable for driving large-diameter valves. If it is used to drive plug valves, ball valves and butterfly valves, the reciprocating motion of the piston must be converted into a rotary motion. In addition to using the piston of a cylinder or a hydraulic cylinder to drive, there is also a pneumatic film drive. Because of its small stroke and driving force, it is mainly used for regulating valves.

Manual valve:

Manual valve is the most basic drive valve. It includes direct drive by handwheel, handle or wrench and drive by transmission mechanism. When the opening torque of the valve is large, it can be driven by gear or worm gear to save effort. Gear transmission is divided into spur gear transmission and bevel gear transmission. Gear transmission reduction ratio is small, suitable for gate valves and globe valves, worm gear transmission reduction ratio is relatively large, suitable for plug valves, ball valves and butterfly valves.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Installation instructions for ball valves

Comparison of pneumatic actuator, electric actuator and hydraulic actuator

Gate valve characteristics and installation notes

What is the positive transmission of gears

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.