Classification of the globe valves-(2)

According to the classification of purposes, the globe valve can be divided into the following types:

12 Globe-valve-4

The fluorine-lined stop valve: it is suitable for various concentrations of aqua regia, sulfuric acid, hydrochloric acid, hydrofluoric acid and various organic acids, strong acids, strong oxidants, and various concentrations of strong alkali organic solvents and other Use on corrosive gas and liquid medium pipelines.

The national standard globe valve: it is the most commonly used product in the globe valve series. The API American standard globe valve and the American standard globe valve implement ANSI and API standards. The sealing surfaces of the disc and seat are made of Stellite cobalt-based hard with different hardness. It is made of alloy surfacing, with reliable sealing, high hardness, wear resistance, high temperature resistance, corrosion resistance, good scratch resistance and long life.

Needle valve: it is a small-caliber instrument valve, which plays a role of opening and closing and precise flow control in the instrument measurement pipeline system. It mainly includes power station instrument series, oil field special series, American standard series, etc.

Cryogenic globe valve: it usually refers to the valve whose working temperature is lower than -110℃, which is widely used in LNG, LPG and other low temperature industries. Since 2008, the globe valve with a suitable temperature of -196℃ can be manufactured, and all parts are pretreated with liquid nitrogen at low temperature to completely avoid seal deformation and leakage during use.

The plunger valve: it is also known as the plunger stop valve. Its sealing surface adopts a radial sealing structure. The load exerted on the valve cover by two elastic sealing rings sleeved on the polished plunger through the connecting bolts of the valve body and the valve cover The elastic sealing ring around the plug compresses the shut-off valve for sealing.

The insulation jacket cut-off valve: it adopts the insulation jacket design, using external heat source to circulate heating outside the valve, which can effectively prevent temperature loss when the medium passes through the valve and ensure the temperature of the medium.

The forged steel globe valve: it is designed and manufactured in accordance with API 602 standards, and provides three bonnet design forms: bolted bonnet, welded bonnet, pressure self-tightening bonnet, users can choose different forms according to their needs, providing RF flanges, NPT thread, SW welding type three connection methods.

The special oxygen stop valve: it is made of silicon brass or stainless steel with excellent material, which has the advantages of high mechanical strength, wear resistance, and good safety. Used in oxygen pipelines, it has the best explosion-proof and flame-retardant performance, eliminates the unsafe factors on the oxygen pipelines, and is widely used in the pipeline network of oxygen-using projects such as steel, metallurgy, petrochemical, and chemical industries. In addition to the functions of ordinary valves, it also has its own characteristics. Strict oil prohibition measures are adopted during manufacturing, and all parts are subjected to strict degreasing treatment before installation.

The bellows stop valve: it adopts a shaped stainless steel bellows design. The bellows reciprocating test is 10,000 times without failure, and the sealing performance is reliable. It is suitable for industrial and mining with inflammable, explosive, toxic and harmful media, and can effectively prevent valve leakage.

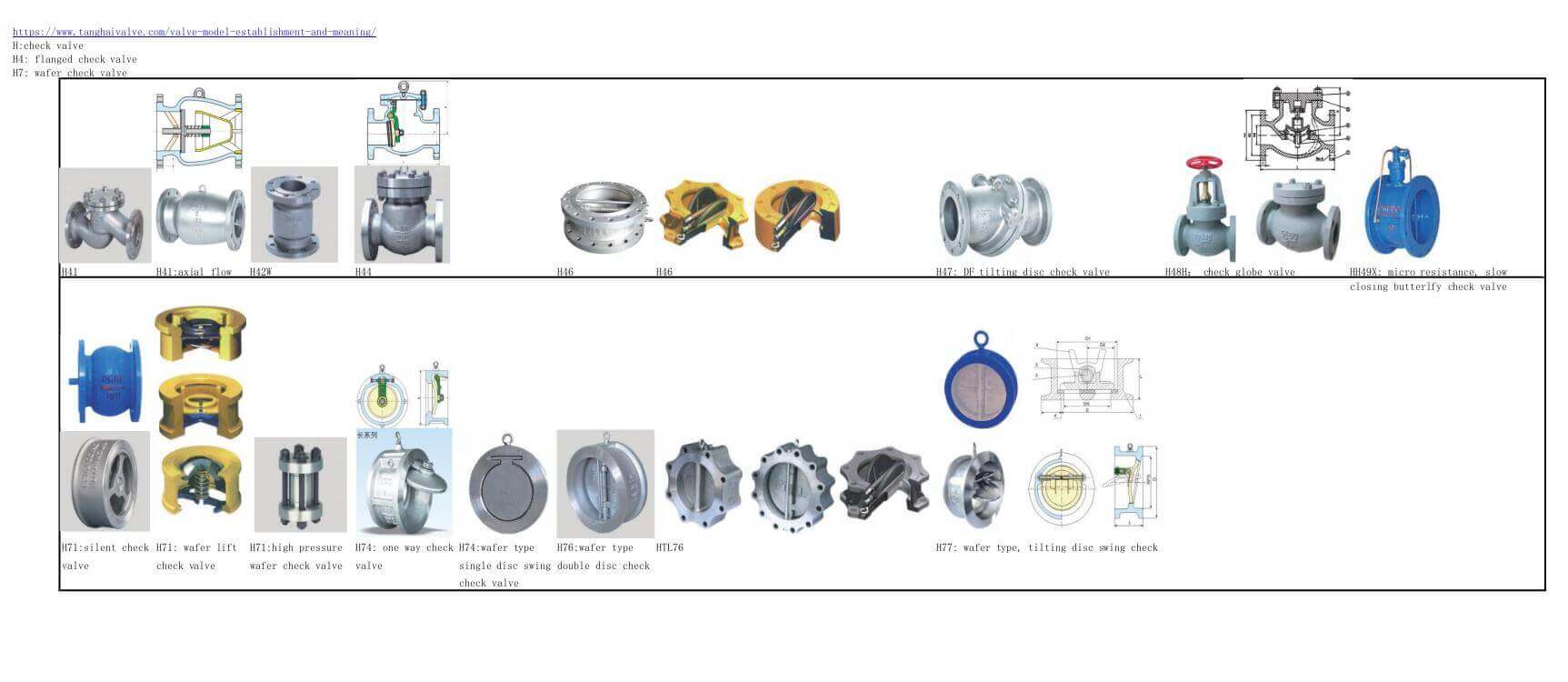

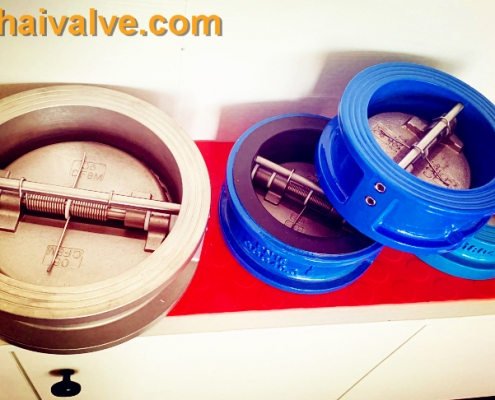

Tianjin Tanghai Valve Manufacturing Co., Ltd. is one of the largest valve manufacturers in China, main products are butterfly valves, check valves, gate valve and globe valves. Details: butterfly valve, lug type butterfly valve, wafer type butterfly valve, U-type butterfly valve, double flange butterfly valve, gate valves, check valves, globe valves, valve parts (Valve body, Valve disc, Valve shaft, Valve seat…)

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.