Factors Affecting the Operation and Use of resilient seated Butterfly Valves

Butterfly valves are classified according to the sealing material, which can be divided into resilient seated butterfly valves and hard-sealed butterfly valves. There is a big difference in the scope of use between the two. The sealing pair of the resilient seated butterfly valve is composed of two parts. One side of the sealing pair is made of metal hard

U-type-flange-butterfly-valve-2

material and the other side is non-metal soft material. This combination makes the resilient seated butterfly valve have good sealing performance and can achieve zero leakage. However, compared with hard-sealed butterfly valves, resilient seated butterfly valves are not suitable for high temperature environments.

The resilient seated butterfly valve is small in size, light in weight, and has good sealing performance. It is responsible for switching on and off and controlling fluid flow in the pipeline system. It has a very wide range of applications in petroleum, chemical, metallurgical, and municipal construction industries.

The connection method of resilient seated butterfly valve is flange type and wafer type. In the process of operating and using resilient seated butterfly valve, some situations are often encountered. Let’s take a look at the factors that affect the operation and use of resilient seated butterfly valve.

- In the valve market, rubber and PTFE are the most commonly used sealing materials for resilient seated butterfly valves. These sealing materials can maximize the sealing performance of resilient seatedbutterfly valves, regardless of whether it is a liquid or a gas medium. Zero leakage. However, because of the limitations of the structural characteristics of these sealing materials, the resilient seated butterfly valve cannot be used in high temperature, high pressure and high-wear circulation pipelines. If any of the above conditions appears in the pipeline, the resilient seated butterfly valve will malfunction and damage.

Fluorine lined butterfly valve-PTFE-WAFER (10)

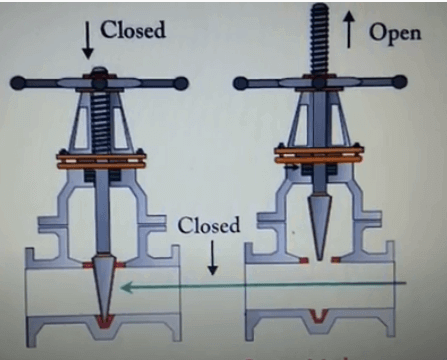

- The sealing ring of the resilient seated butterfly valve is fixed on the valve plate. When the butterfly plate of the butterfly valve is in the open position, the fluid medium in the pipeline will flush the sealing surface of the butterfly valve positively. Under the long-term erosion and corrosion of the fluid medium, the resilient seated material will wear out over time, which will affect the sealing performance of the resilient seated butterfly valve and cause leakage.

The factors that affect the operation of the resilient seated butterfly valve are the above two points. After the operator understands this information, he must pay attention to the use of the resilient seated butterfly valve, master the correct operation method of the resilient seated butterfly valve, and regularly perform maintenance and repairs to maximize the resilient seated butterfly valve Play a role and serve our industrial production.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

resilient seated butterfly valve vs metal seated butterfly valve;

Resilient seated socket end gate valve;

What are the main factors affecting valve sealing?

Installation requirements for manual butterfly valves

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.