Excellent environmental protection characteristics of soft sealing gate valve

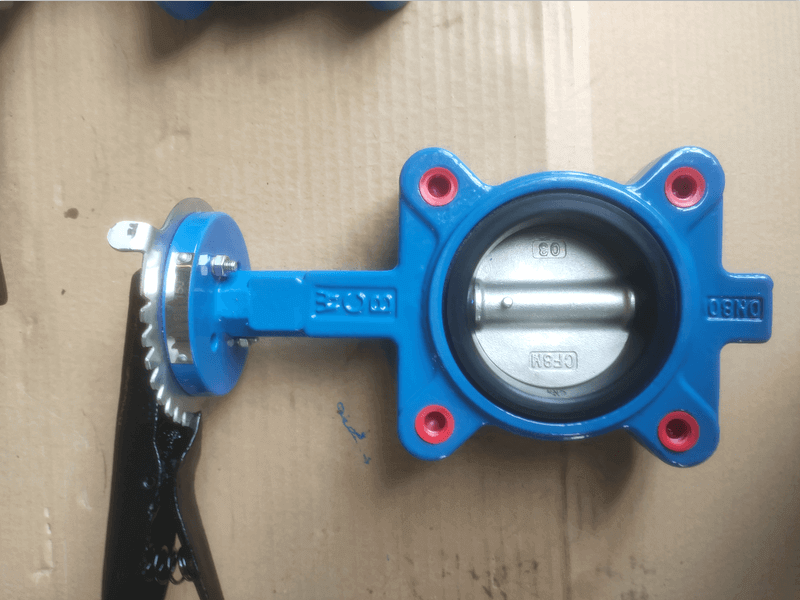

In many working conditions, gate valves are more used to cut off water bodies such as pure water and tap water. Among them, the soft seal gate valve is an updated product of the ordinary gate valve. Generally speaking, as long as one side between the gate and the valve seat is made of soft material instead of metal, it can be called a soft seal. The

AWWA C509-C515-resilient seated wedge gate valve-DN80-150lb (4)

more common one is fluorine or rubber lining. The rubber-lined soft-seal gate valve we mentioned today mainly uses the overall nitrile rubber encapsulation outside the gate, and uses the softness of the rubber to seal the valve to achieve zero leakage in the valve. In addition to the advantages of sealing, the environmental protection characteristics of soft-seal gate valves are also excellent.

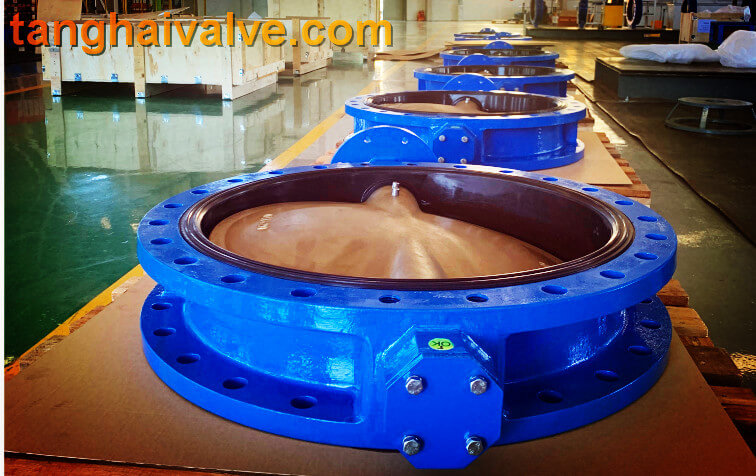

The gate plate of the soft-seal gate valve is made of pollution-free rubber material, and the inside and outside of the valve are sprayed with non-toxic epoxy resin electrostatically. This spraying process is advanced and environmentally friendly. It not only makes the appearance of the product smoother and more beautiful, but also does not produce rust water, which can meet the requirements of direct drinking water. Tanghai Valve has invested a huge amount of money to introduce an electrostatic spraying automatic assembly line, which has faster work efficiency. The soft sealing gate valve of Tanghai Valve is also widely used in fluid pipelines such as tap water, sewage, construction, fire fighting, HVAC, metallurgy, energy systems, etc., as a shut-off device. Under the country’s strong environmental protection call, some small factories with unsound qualifications but not enough to shut down have been forced to close under pressure. However, Tanghai Valve has steadily increased its sales due to the green and environmental characteristics of its products.

The soft sealing gate valve produced by Tanghai has extremely low resistance and light switch. At the same time, the “O” type sealing ring is adopted, which is reliable in sealing. The unique design structure enables the “O” type ring to be replaced under pressure, without pressing the packing, and free of maintenance. If you need gate valve products with high environmental performance, you will come to Tanghai Valve. After-sales quality is guaranteed, environmental protection quality is passed.

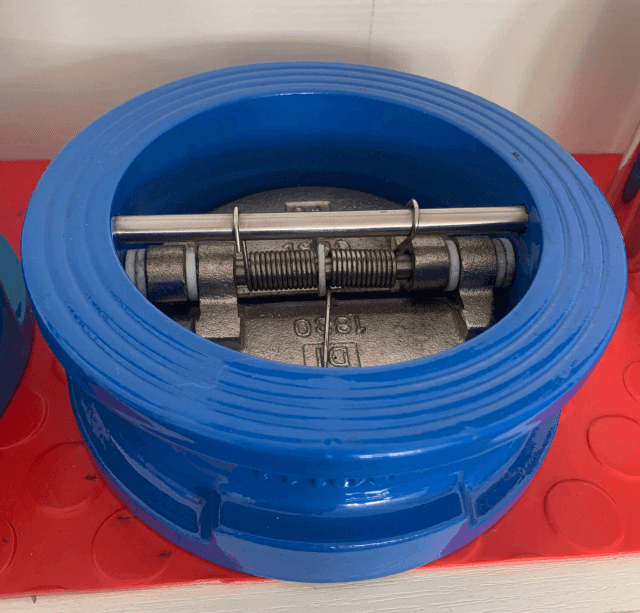

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

The difference and selection of electric valve and pneumatic valve

Difference between Soft seal gate valve and hard seal gate valve

Difference between soft seal butterfly valve and hard seal butterfly valve

Lining material and its application scope of fluorine lined valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.