Flange butterfly valve is more suitable for large and medium diameter pipelines

Commonly used butterfly valves include wafer butterfly valves, flanged butterfly valves and welded butterfly valves. Wafer type butterfly valve uses double-head bolts to connect the valve between two pipe flanges. Flange type

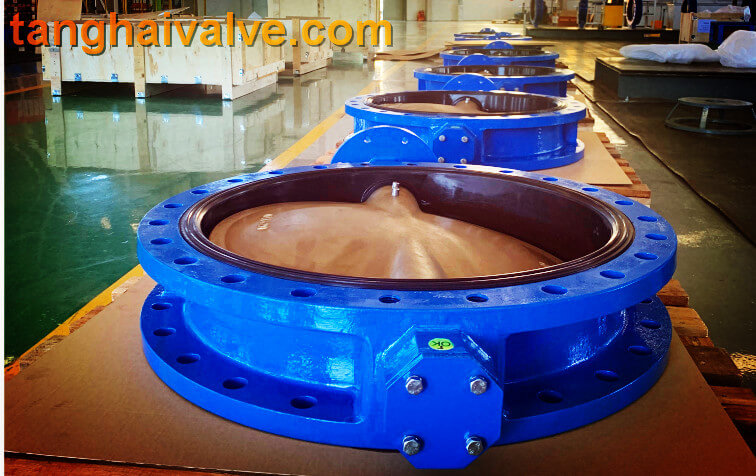

Double flange butterfly valve (16)

butterfly valve has flanges on the valve, and bolts are used to connect the flanges at both ends of the valve to the pipe flanges. The welding butterfly valve, as its name implies, is to weld the butterfly valve directly to the pipeline. The groove of the butt welding butterfly valve corresponds to the groove on the pipeline, and the welding rod is used to weld it. This type of connection is generally used in the case of high pressure media. Because welding is not easy to disassemble, the quality of the butterfly valve is required to be very high, and the price is naturally relatively high. Therefore, when DN50-300, flanged butterfly valve can be used, which is a cost-effective choice.

The flanged butterfly valve has its own flanges on both sides of the valve. Usually the flange and the valve body are cast together, so that the applicability to the pipeline is relatively strong, and it has the advantages of convenient installation and firmness. It is mainly used as a cut-off valve. Can have the function of a regulating valve. At present, flanged butterfly valves are used more and more on large and medium diameter, low pressure pipelines.

The butterfly plate of the flange butterfly valve is installed on the diameter side of the pipeline. The structural principle is very suitable for making large-diameter valves and has good fluid control characteristics. When the flange butterfly valve is in the fully open position, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body. The larger the diameter, the lower the pressure. Therefore, the pressure drop generated by the flange butterfly valve is very small, so the flange butterfly valve can Actively play a role in large-diameter pipelines.

Flange butterfly valves are not only widely used in general industries such as petroleum, gas, chemical, water treatment, etc., but also used in cooling water systems of thermal power stations. The future market development prospects are bright.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

What is butt welding? (1)

Classification and characteristics of welding

Electric flange ball valve installation instructions

Structural characteristics of butterfly valve

tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.