Selection criteria for check valve:

The selection criteria for check valves are as follows:

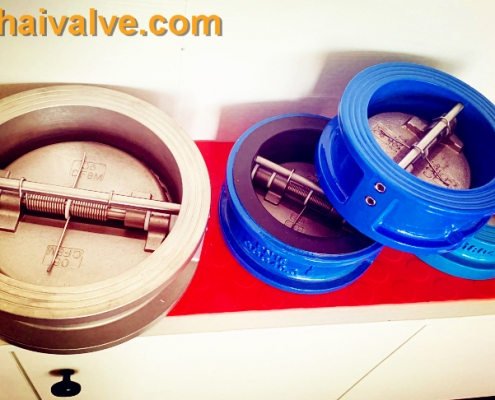

double-wing-check-valve-3

1. In order to prevent the medium from flowing back, check valves should be installed on equipment, devices and pipelines;

2. Check valves are generally suitable for clean media, not for media containing solid particles and high viscosity;

3. Generally, horizontal lift check valves should be used on horizontal pipes with a nominal diameter of 50mm;

4. The straight-through lift check valve can only be installed in horizontal pipelines;

5. For the inlet pipeline of the water pump, a bottom valve should be used. The bottom valve is generally only installed on the vertical pipeline at the pump inlet, and the medium flows from bottom to top;

6. Compared with the swing type, the lifting type has better sealing performance and greater fluid resistance. The horizontal type should be installed on the horizontal pipeline, and the vertical type on the vertical pipeline;

7. The installation position of the swing check valve is not restricted. It can be installed on a horizontal, vertical or inclined pipeline. If installed on a vertical pipeline, the medium flow direction should be from bottom to top;

8. The swing check valve should not be made into a small-diameter valve, it can be made into a high working pressure, the nominal pressure can reach 42MPa, and the nominal diameter can also be large, the maximum can reach more than 2000mm. It can be applied to any working medium and any working temperature range according to the different materials of the shell and the seal. The medium is water, steam, gas, corrosive medium, oil, medicine, etc. The working temperature range of the medium is between -196–800℃;

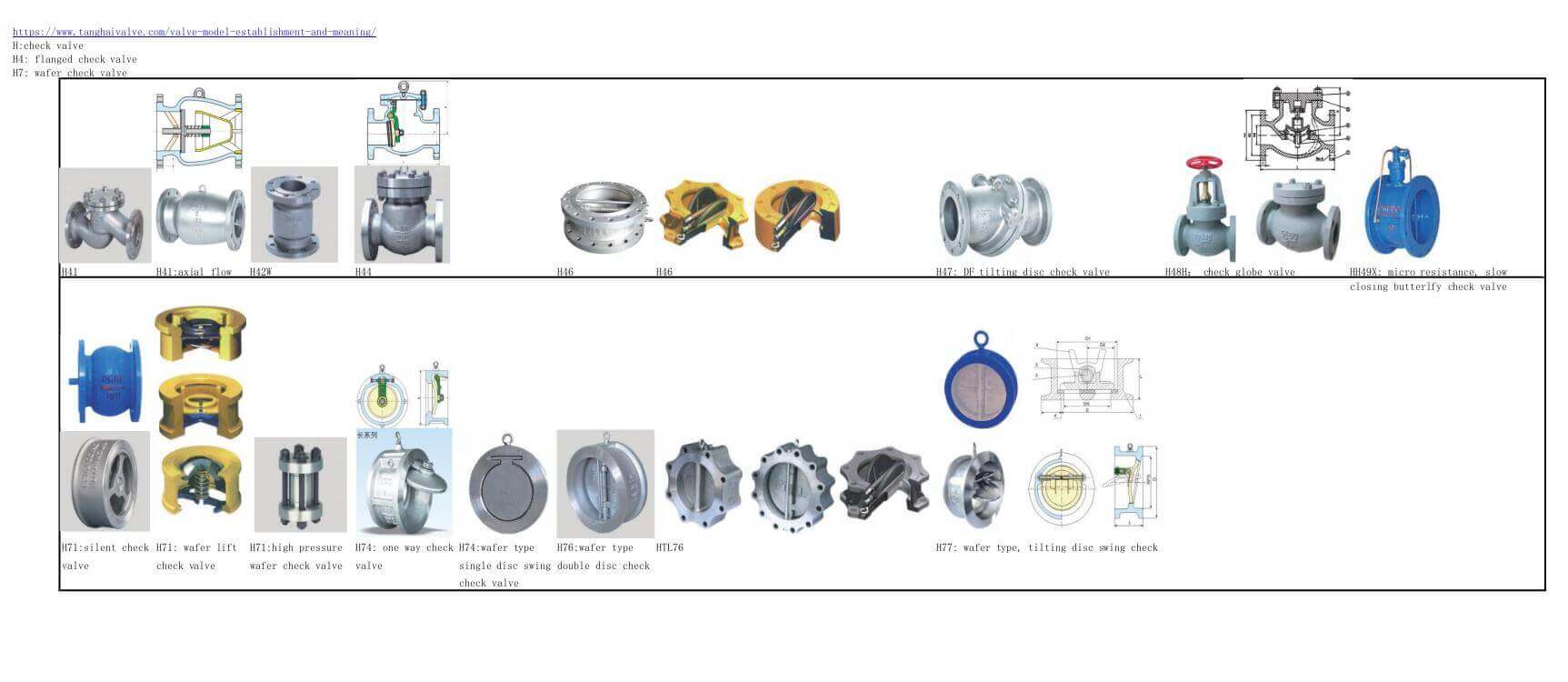

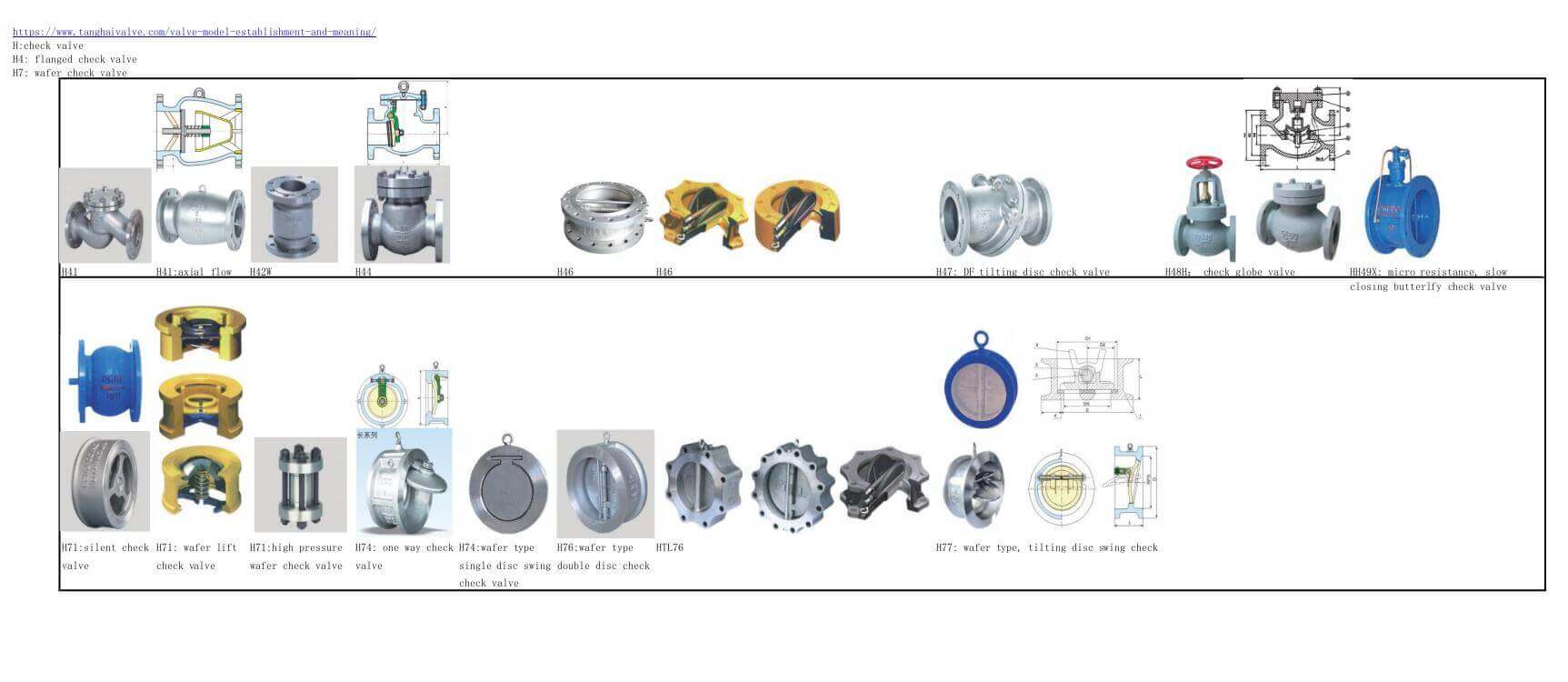

all types of check valve and structures -code names-photos

9. The applicable occasion for swing check valve is low pressure and large diameter, and the installation occasion is restricted;

10. The installation position of the butterfly check valve is not restricted. It can be installed on a horizontal pipeline or on a vertical or inclined pipeline;

11. Diaphragm check valve is suitable for pipelines that are prone to water hammer. The diaphragm can well eliminate the water hammer caused by the backflow of the medium. It is generally used on low-pressure and normal temperature pipelines, and is especially suitable for tap water pipelines. Normal media work The temperature is between -12-120℃, and the working pressure is less than 1.6MPa, but the diaphragm check valve can achieve a larger diameter, and the maximum DN can reach more than 2000mm;

12. The spherical check valve is suitable for medium and low pressure pipelines and can be made into a large diameter;

13. The shell material of the spherical check valve can be made of stainless steel, and the hollow sphere of the seal can be wrapped with polytetrafluoroethylene engineering plastics, so it can also be applied to the pipeline of general corrosive media, and the working temperature is -101–150 ℃, its nominal pressure is ≤4.0MPa, and the nominal passage range is between DN200-DN1200;

14. When selecting a check valve for incompressible fluids, the required closing speed must be evaluated first, and the second step is to select the type of check valve that may meet the required closing speed;

15. The check valve for compressible fluid can be selected according to the similar method of check valve for incompressible fluid. If the medium flow range is large, the check valve for compressible fluid can be used A deceleration device, if the medium flow is stopped and started quickly and continuously, such as the outlet of the compressor, a lift check valve is used;

16. The corresponding size of the check valve should be determined, and the valve supplier must provide the data of the selected size, so that the valve size when the valve is fully opened at a given flow rate can be found;

17. For high and medium pressure check valves below DN50mm, vertical lift check valves and straight-through lift check valves should be used;

18. For low-pressure check valves below DN50mm, butterfly check valves, vertical lift check valves and diaphragm check valves should be used;

19. For high and medium pressure check valves with DN greater than 50mm and less than 600mm, swing check valves should be used;

20. For medium and low pressure check valves with DN greater than 200mm and less than 1200mm, wear-free spherical check valves should be used;

21. For low-pressure check valves with a DN greater than 50mm and less than 2000mm, butterfly check valves and diaphragm check valves should be used;

22. For pipelines that require relatively small water hammer impact or no water hammer when closed, slow-close swing check valves and slow-close butterfly check valves should be selected.

Related news /knowledge:

All types of check valve and its structures;

What is vertical check valve;

Use performance and working principle of vertical check valve;

Installation method and precautions of check valve;

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.