Advantages and Disadvantages of Centerline Butterfly Valves

Advantages of Centerline Butterfly Valves

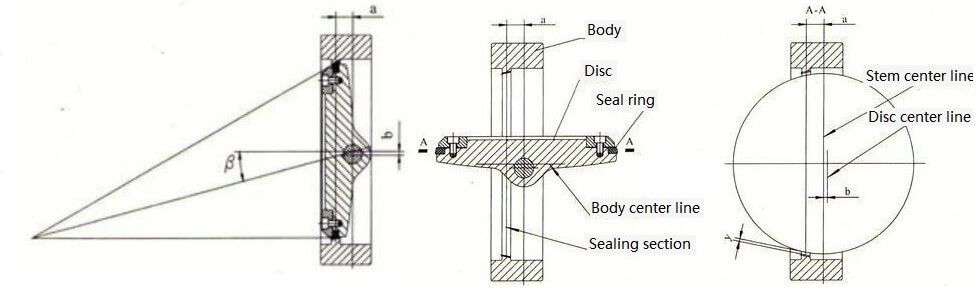

The centerline butterfly valve adopts the centerline sealing structure, and the centerline of the disc sealing of the butterfly valve is consistent with the centerline of the valve body and the rotation centerline of the valve stem. The upper and lower ends of the butterfly plate near the

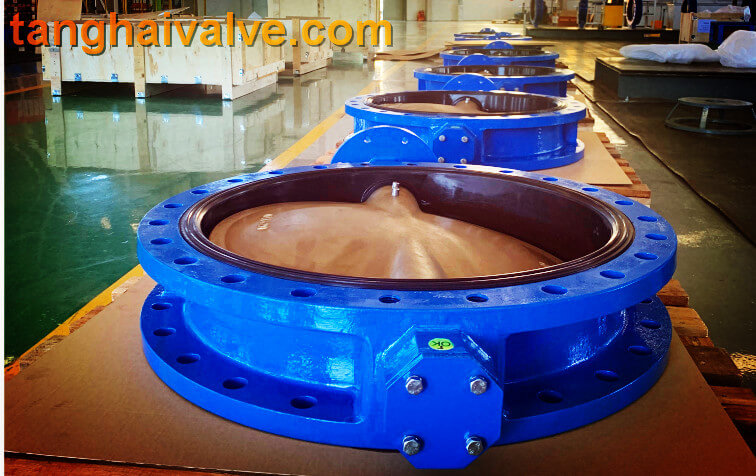

Double flange butterfly valve (16)

valve stem are designed as two smooth planes, and are in close contact with the valve seat gasket made of rubber to ensure that the medium does not leak from both ends; the outer edge of the butterfly plate is designed as a spherical outer edge, It should be ensured that the arc surface has a suitable surface roughness during processing, and the seat gasket should ensure that the sealing surface has a suitable surface roughness during molding. When the valve is closed, the butterfly plate rotates 0-900 degrees, and gradually compresses the valve seat gasket made of rubber, so that the elastic force formed by the elastic deformation of the valve seat gasket is used as the necessary sealing pressure to ensure the sealing of the valve.

The centerline butterfly valve is designed to reduce flow resistance:

1) The channel is designed as a full-diameter structure, which ensures the flow area of the valve and reduces the flow resistance when the fluid passes through the valve.

2) The butterfly plate adopts the disc-shaped streamline design, which can not only ensure the stress intensity in the center of the butterfly plate, but also ensure that the valve can obtain a larger flow coefficient and a smaller fluid resistance coefficient.

3) The valve seat sealing ring is designed as a soft sealing structure of rubber and resin skeleton (fixed sleeve), which is embedded in the valve body after being manufactured. The part of the inner ring higher than the inner cavity of the valve body adopts a streamline design to achieve the purpose of reducing the flow resistance.

Disadvantages of Centerline Butterfly Valves

Because of its own structure, the centerline butterfly valve can only be made into a soft-sealed butterfly valve, so the centerline butterfly valve can only be used in the working environment of low pressure and normal temperature, and is not suitable for high temperature and high pressure conditions.

The above is the introduction of the advantages and disadvantages of the centerline butterfly valve

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news /knowledge:

electric hard seal butterfly valve vs electric soft seal butterfly valve

Installation and operation method of manual butterfly valve

Characteristics of the centerline wafer butterfly valve

Vulcanized vs soft seated/back-up butterfly valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.