Sealing Surface Structure of Handle Wafer Type Butterfly Valve

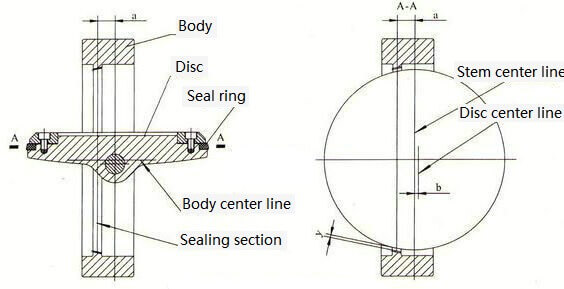

The sealing surface structure of the handle wafer butterfly valve is the key to ensure the reliable sealing of the valve and an important basis for judging the performance of the valve. The sealing performance is related to whether the butterfly valve can perform normal adjustment and cut off the medium work. In general, the sealing surface is

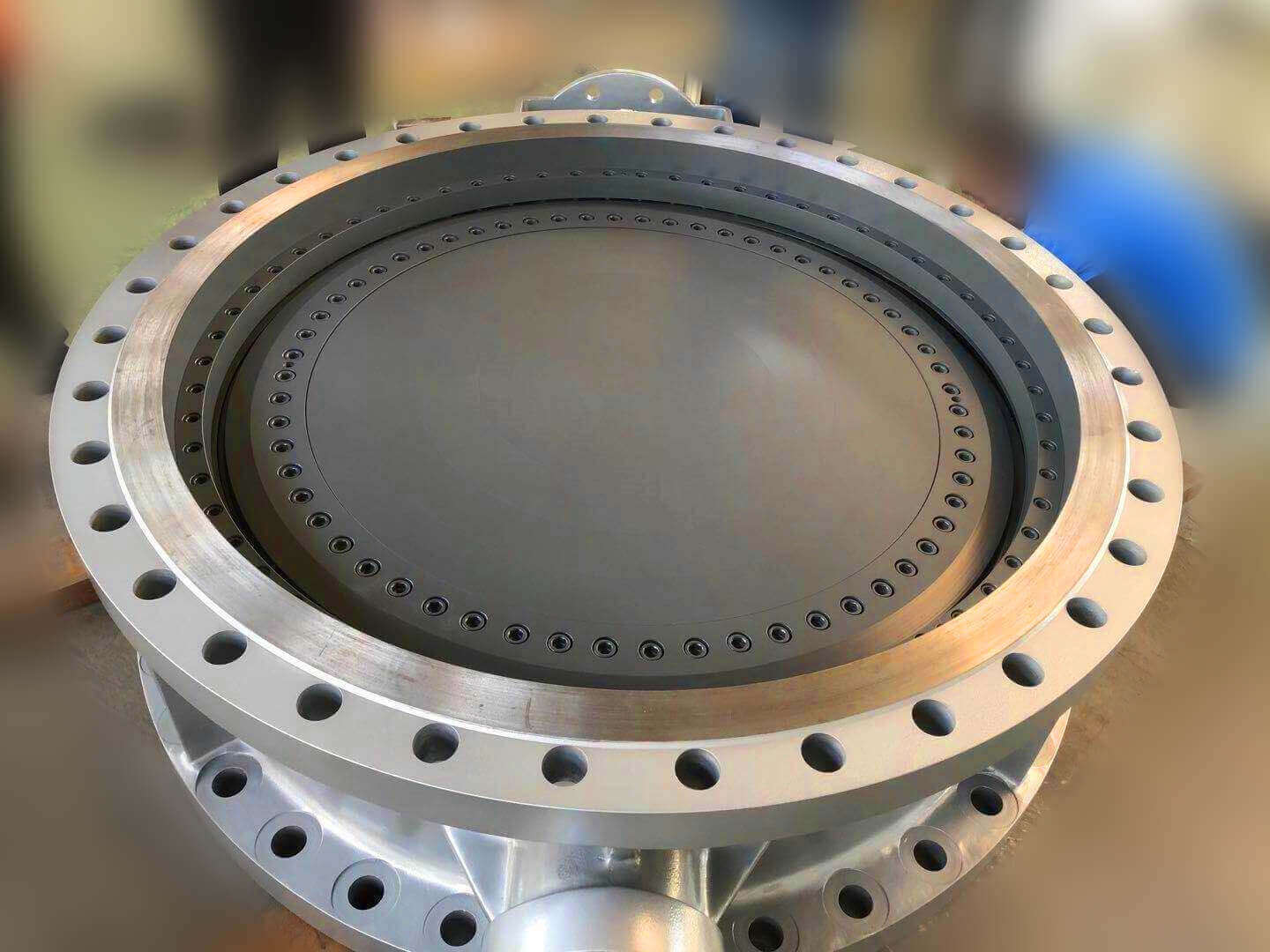

JIS 10K-wafer butterfly valve-backup seat (1)

composed of the valve seat and the disc of the wafer butterfly valve. It depends on the close contact between the valve seat and two or more precision-machined and ground sealing surfaces on the disc, or the sealing surface is produced by pressure. The sealing is achieved by plastic deformation.

The sealing surface of the handle wafer butterfly valve:

1. Resistant to medium corrosion;

2. Wear resistance and friction;

3. Ensure reliable sealing under the current working conditions;

4. Good processing technology;

5. Easy to assemble and maintain.

The sealing surface form of the handle wafer butterfly valve:

The sealing surface of the valve has several forms, including flat seal, cone seal, spherical seal, and knife seal. The handle wafer butterfly valve is mainly flat seal and spherical seal. The concept of flat seal is that the two contact surfaces of the seal are flat. Compared with several other sealing forms, the flat seal has its own unique advantages, the most important being the convenience of processing and repair. If it is used on the globe valve, it can also make the valve open and close without friction at the moment. Spherical seal means that one of the two contact surfaces of the seal is spherical. Butterfly valves with good sealing performance, ball valves and some small-diameter globe valves are used more. The advantage of the spherical seal is that the seal is larger and the sealing performance is good, but the disadvantage is that the maintenance is more difficult.

There are many fastening forms for the sealing surface of the handle wafer butterfly valve, which are mainly determined according to the conditions of the medium used, such as the pressure, temperature, corrosiveness of the medium, and the properties of the material of the sealing ring and the material of the housing. The basic requirements for the tightening of the valve sealing ring are that the joint surface has good sealing, easy processing, convenient maintenance, reliable connection and durability.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of center-lined butterfly valve:

Related news/knowledge:

Purchasing precautions for handle butterfly valves

Introduction to the Features of Lever Wafer Butterfly Valve

The correct operation method of manual valve

Working principle and characteristics of triple eccentric butterfly valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.