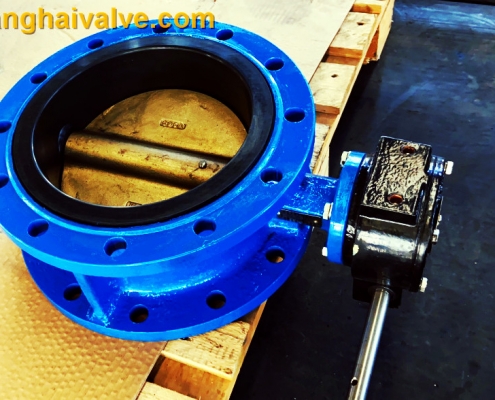

Installation instructions of double eccentric butterfly valve

Installation instructions of double eccentric butterfly valve:

1. Before installation, you must carefully check whether the valve’s mark and certificate of conformity meet the requirements for use, and clean it after verification.

Double eccentric-wafer butterfly valve-D72F-150lbP-stainless steel (3)

Uninstalled valves should be stored in a dry room. Valves stored for a long time should be cleaned regularly, dried and coated with anti-rust oil. Blind plates shall be used to protect the flange sealing surface at both ends of the valve.

2. Install according to the flow direction of the medium; horizontal installation is preferred.

3. The connecting bolts of the butterfly valve and the pipeline should be tightened several times in the diagonal direction during installation, and no single piece should be tightened at a time to prevent the flange connection from leaking due to uneven force.

4. When installing the butterfly valve, the butterfly plate should be in the closed position to prevent debris from entering the valve cavity and scratching the sealing surface. When the user wants to test the pressure, be sure to install the flange pair on both ends and test the pressure.

5. When connecting the valve to the pipeline, it is required to use butt-welded steel flanges or special butterfly valve flanges on the pipeline. If flat-welded steel flanges are used, the inner hole of the flange must be the same size as the inner hole of the gasket to ensure the effective sealing surface of the gasket.

6. When the electric butterfly valve leaves the factory, the opening and closing stroke of the control mechanism has been adjusted. In order to prevent the direction from being wrong when the power is turned on, the user must manually move to 1/3 of the closed position before turning on the power for the first time. And check whether the direction of the indicator plate is consistent with the opening direction of the valve.

7. When the valve is in use, if any malfunction is found, stop using it immediately

Tanghai Valve is the best manufacturer of double eccentric butterfly valve in China. We produce the best quality products with competitive low prices. Main products: butterfly valve, lug type butterfly valve, wafer type butterfly valve, U-type butterfly valve, double flange butterfly valve, gate valves, check valves, globe valves, valve parts (Valve body, Valve disc, Valve shaft, Valve seat…)

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Description of valve pressure& installation direction requirements;

The sealing characteristics and principle of eccentric butterfly valve;

What is double plate swing check valve;

Selection and application of eccentric butterfly valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.