What is the material of Bolts and nuts of Valve Stem?

Bolts and nuts material of valve stem:

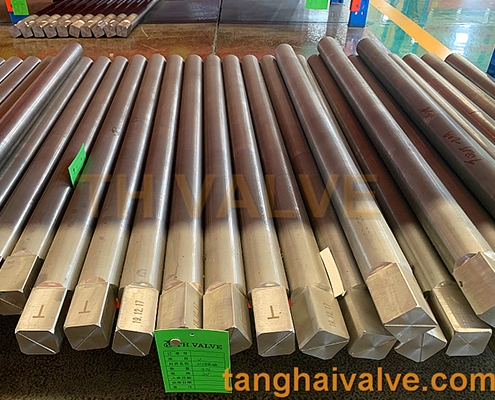

bolts and nuts for butterfly valve

The stem nut directly bears the axial force of the stem during the opening and closing of the valve, so it must have a certain strength. At the same time, it and the valve stem are threaded transmission, which requires a small friction coefficient, no rust and avoid seizure.

1. Copper alloy Copper alloy has a small friction coefficient and does not rust. It is one of the commonly used materials. For low pressure valves with Pg<1.6Mpa, ZHMn58-2-2 cast brass can be used. ZQAL9-4 Wuxi bronze can be used for Pg16-6.4Mpa medium pressure valve. For high-pressure valves, ZHAL66-6-3-2 cast brass can be used.

2. Steel When the working conditions do not allow the use of copper alloys, high-quality carbon steels such as 35 and 40 can be selected, and stainless acid-resistant steels such as 2Cr13, 1Cr18Ni9, and Cr17Ni2 can be used. Working conditions are not allowed to refer to the following situations.

1. For electric valves, stem nuts with melon clutches need heat treatment to obtain high hardness or surface hardness.

2. When the working medium or the surrounding environment is not suitable for copper alloy, such as ammonia medium that corrodes copper. When selecting steel stem nuts, pay special attention to thread seizure.

Tianjin Tanghai Valve Manufacturing Co., Ltd. is one of the largest valve bolts and nuts manufacturers in China, main products are butterfly valves, check valves, gate valve and globe valves. Key words: butterfly valve, lug type butterfly valve, wafer type butterfly valve, U-type butterfly valve, double flange butterfly valve, gate valves, check valves, globe valves, valve parts (Valve body, Valve disc, Valve shaft, Valve seat…)

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.