The difference between a float valve and a ball valve

The difference between a float valve and a ball valve, the principle of the float valve | diagram

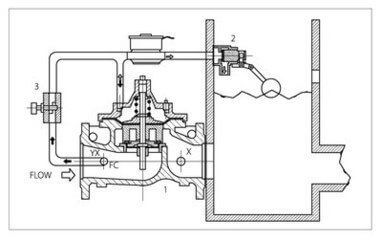

Float valve is a product of liquid level measurement and control. It is constructed by several main components such as valve body, piston, connecting rod and floating ball, and uses the principle of leverage to make the valve open or block. In the simplest way, it is like a flush toilet at home, and the water supply device used on it has this structure.

The difference between float valve and ball valve:

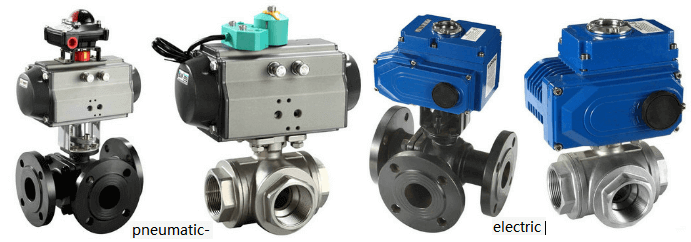

electric ball valve

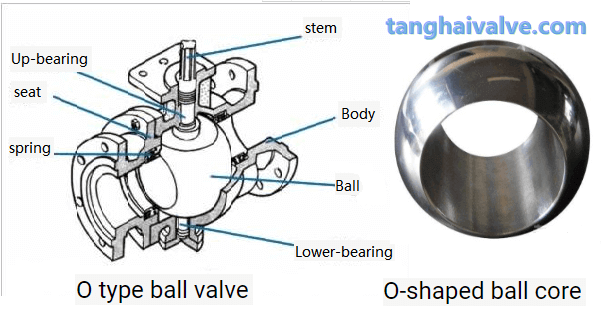

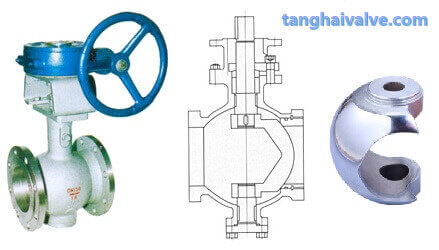

The ball valve is a kind of valve, which refers to the valve core (sealing part) of the valve with a spherical structure, which is used in the pipeline to block air or water flow; the float valve is because one end of the switch lever is a hollow sealing ball, Automatically control the opening and closing of the valve through the buoyancy of the liquid. One word difference is very different.

The working principle of the float valve|Illustration:

The float valve floats must always float on the water. When the water surface rises, the float also rises. When the

principle of the float valve diagram

water level of the water tank is low, the floating ball decreases with the water level, and the piston in the valve body is pulled out through the connecting rod of the fixed floating ball, so that the valve body and the piston are hollowed out, so that the tap water can enter the water tank; when the water level of the water tank is set When the height position is high, the force generated by the floating ball as the water level rises pushes the piston in the valve body into the valve body through the connecting rod. Because the top of the piston is equipped with a sealing rubber gasket, the water outlet in the valve body is processed relatively flat and smooth. When the buoyancy of the floating ball exceeds the pressure of the tap water, the piston with the sealing rubber gasket and the water outlet in the valve body are tightly sealed, and the tap water is closed by the floating ball valve.

Floating ball valve function: control the water level of the pool or water tank not to exceed a certain set value, and the valve can only be opened within a set time period. Floating ball valve is applicable: used in the reservoir system of the tap water supply pipe network to avoid opening the reservoir inlet valve during peak water consumption and reduce the pressure of the water supply pipe network. The valve can only open when the water is low.

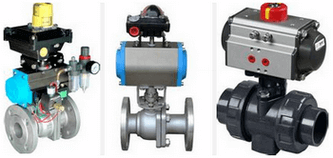

Click to view: Principle of Ball Valve Principle of Electric Ball Valve Principle of Pneumatic Ball Valve

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news /Products:

The role and use of the ball valve;

Types and classifications of ball valves;

The difference between fixed ball valve and floating ball valve;

Working Principle of Pneumatic Gate Valve;

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.