Comparison of pin butterfly valve and pinless butterfly valve

We often hear such statements as pinless butterfly valves and pinless butterfly valves in the purchase of butterfly valves. Because of technological reasons, pinless butterfly valves are usually more expensive than pinned butterfly valves. This makes many customers think whether pinless butterfly valves are more expensive than pinless butterfly valves. Is it better to have a pin butterfly valve? How does a pin butterfly valve compare with a pinless butterfly

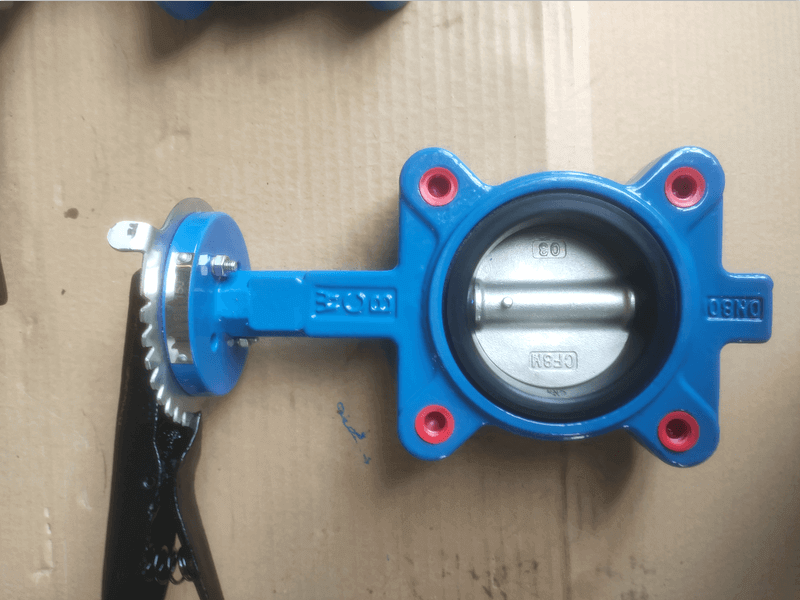

Wafer butterfly valve-PN20-WCB-ANSI-150 (3)

valve? This article introduces Tanghai Valve for you.

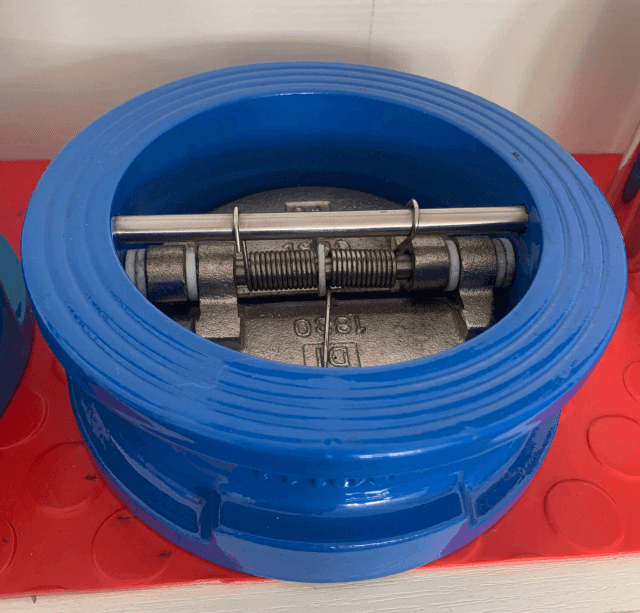

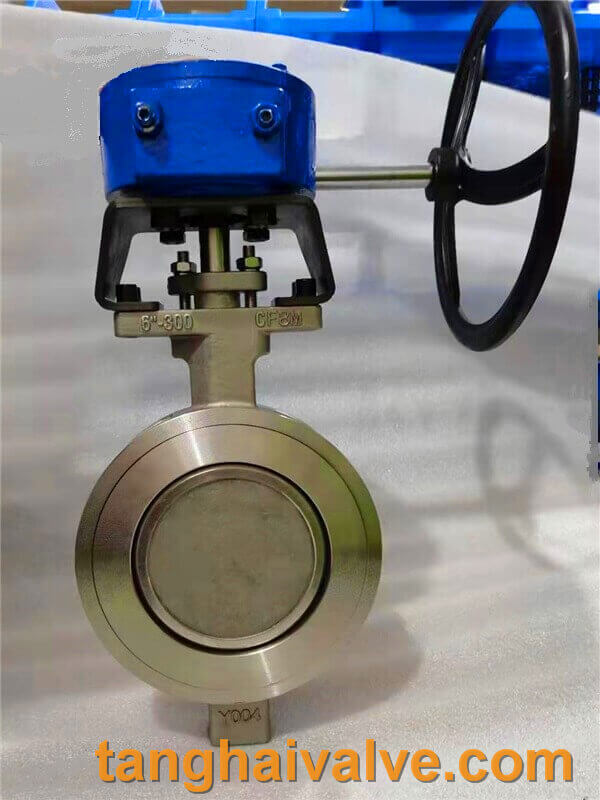

From the appearance point of view of the pin butterfly valve and the pinless butterfly valve, the most essential difference is whether there is a tapered pin positioning on the valve plate. The connection method that uses a pin to penetrate the valve plate and the valve stem is a pin butterfly valve, and vice versa is a pinless butterfly valve. For pin butterfly valves and pinless butterfly valves, they have their own advantages and disadvantages. The specific situation is as follows:

Appearance comparison-the pinned butterfly valve has obvious pin head protrusions, which is not as smooth and beautiful as a pinless butterfly valve, but in fact it does not have a huge impact on the overall appearance.

Process comparison-the structural processing technology of the pin butterfly valve will be relatively simple, but if it needs to be repaired after long-term use, it will be more troublesome to disassemble the shaft and valve plate. Because the pin usually hit is that the pile pin is hard pressed up with a press, it is not easy to take out the valve stem. The pinless butterfly valve is relatively complicated in structure and technology because of the different ways of

wafer-type-butterfly-valve-with-handle-13

transmitting torque, but the later maintenance and disassembly are more convenient and convenient for repair.

Stability comparison——Because the pin butterfly valve is fixed with pins, the stability is definitely better than the pinless structure. The pinless structure affects the accuracy of the action due to the wear of the mating surface of the axle and the gate after long-term action. Therefore, the quality of pinless butterfly valves produced by manufacturers without mature processing technology and equipment is more worrying. This is also to remind customers and friends that if there is a demand for non-sold butterfly valves, you must choose a manufacturer with sound qualifications and mature production experience like Tanghai Valve. After all, Tanghai Valve has been in the valve manufacturing industry for 24 years, and it will be more professional in terms of quality, craftsmanship and management.

Sealing comparison-Finally, let’s take a look at the comparison of sealing effects. There is a saying that in actual use, the pin butterfly valve may see the medium from the pinned place to between the valve plate and the valve stem. The hidden danger brought by this is that the pin will be corroded and broken after a long time, causing the valve to fail to work, or the ejector rod leakage or the internal leakage of the pipeline. However, many manufacturers have begun to notice this problem. For example, Tanghai will choose to weld a layer of pins on the valve plate and shaft to prevent leakage from the pins.

In summary, compared with pin butterfly valves and pinless butterfly valves, objectively speaking, each design has its own characteristics and advantages, and one cannot simply say which one is better. As long as we choose the product that is most suitable for our cost budget and most suitable for our working conditions, it is a good product that suits us.

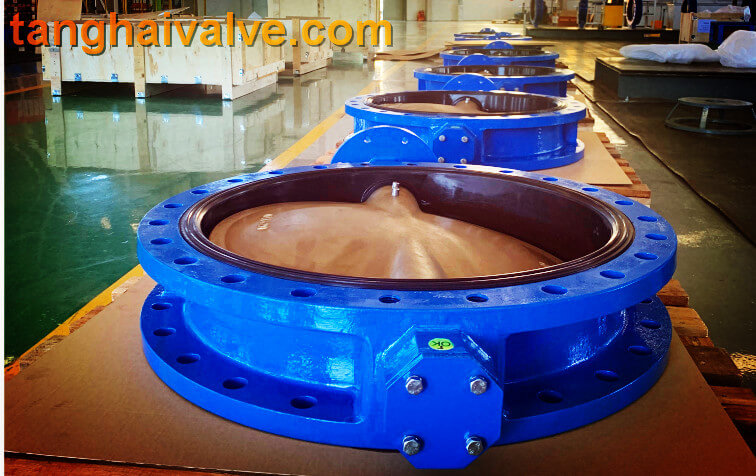

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Structural characteristics & features of flanged butterfly valves

Comparison of bellows globe valve and ordinary globe valve

What is the material of the main parts of the butterfly valve?-(2)

Comparison of pneumatic actuator, electric actuator and hydraulic actuator

maintained under the working conditions of dirty media. The valve seal can be replaced without removing the valve, making the valve maintenance easier.

maintained under the working conditions of dirty media. The valve seal can be replaced without removing the valve, making the valve maintenance easier.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.