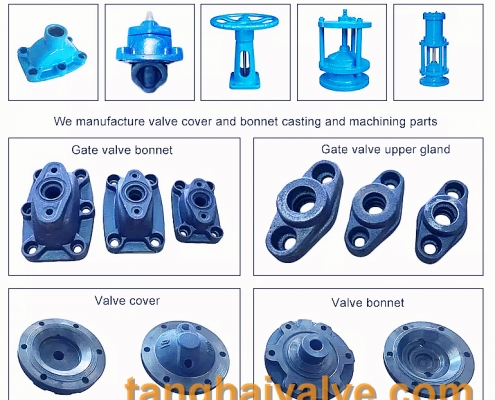

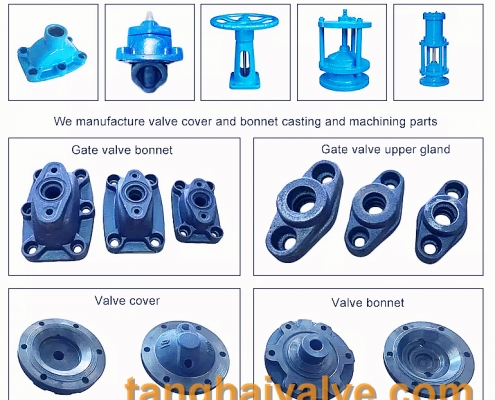

There are many other valves parts and 1. Fastener material of valves:

valve bonnets

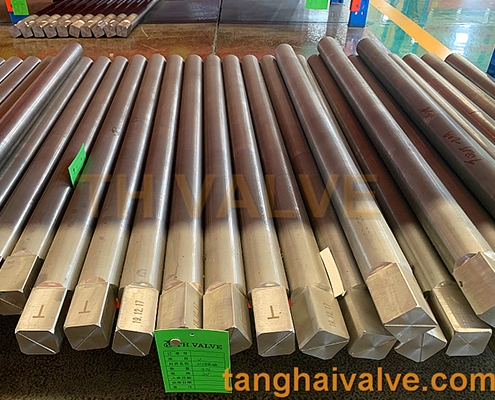

Fasteners mainly include bolts, studs and nuts. The fastener directly bears the pressure on the valve, which plays an important role in preventing the outflow of the medium. Therefore, the selected material must ensure sufficient strength and impact toughness at the operating temperature. When selecting fastener materials according to medium pressure and temperature, you can choose according to Table 5-1. Name Nominal Pressure Pg (Mpa) Medium Temperature (℃) 300 350 400 425 450 530 Bolt Stud Bolt 1.6-2.5 A3 35 30CrMoA _4.0-10.0 35 35CrMoA 25Cr2MoVA16.0-20.0 30CrMoA 35CrMoA 25Cr2MoVA Nut 1.6-2.5 A3 30 35 _4.0-10.0 30 35 35CrMoA16.0-20.2 35 35CrMoA Table 5-1 must undergo heat treatment when selecting alloy steel materials. When there are special corrosion resistance requirements for tight-return parts, stainless and acid-resistant steels such as Cr17Ni2, 2Cr13, 1Cr18Ni9 can be selected.

2. Filler material of valves:

On the valve, the packing is used to fill the space of the valve cover packing chamber to prevent the medium from leaking through the valve stem and the valve cover packing chamber space.

1. Requirements for packing 1) Good corrosion resistance, the packing must be able to withstand the corrosion of the medium in contact with the medium. 2) The sealing is good, and the packing will not leak under the action of the medium and working temperature. 3) The friction coefficient is small to reduce the friction torque between the valve stem and the packing.

2. Types of fillers Fillers can be divided into two types: soft fillers and hard fillers: 1) Soft fillers: are made of plant materials, namely hemp, flax, cotton, jute, etc., or are made of minerals, that is, asbestos fibers, or Wire ropes braided by asbestos fibers with metal wires inside and graphite powder coated on the outside, as well as pressed shaped fillers, and flexible graphite filler materials newly developed in recent years. Plant-based packing is cheaper, and is often used for low-pressure valves below 100°C; mineral packing can be used for valves with 450-500°C. In recent years, the structure of using rubber O-rings as packing has been gradually promoted, but the temperature of the medium is generally limited to below 60℃. The packing on the high temperature and high pressure valve is also compacted with pure asbestos and flake graphite powder. 2) Hard filler: that is, filler made of metal or metal mixed with asbestos and graphite and filler formed by pressing and sintering of polytetrafluoroethylene. Metal filler is used less.

3. The choice of packing The packing should be selected according to the medium, temperature and pressure. Commonly used materials are as follows: 1) Oil-impregnated asbestos rope, which can be selected according to Table 5-2. 2) Rubber asbestos rope: can be selected according to Table 5-3. 3) Graphite asbestos rope: The asbestos rope is coated with graphite powder. The usable temperature is above 450℃ and the pressure can reach 16Mpa. It is generally suitable for high-pressure steam. Lately, it gradually adopts the compression-shaped packing, which is placed in a single circle and has good sealing performance. 4) Polytetrafluoroethylene: This is a filler that is currently widely used. Especially suitable for corrosive media, but the temperature should not exceed 200℃. It is generally made by pressing or bar stock, and its shape is shown in Figure 5-1. Name, brand, shape and specification (diameter or square side length) Applicable ultimate pressure kgf/cm2 Applicable ultimate temperature (℃) Purpose Oil-impregnated asbestos rope YS450 F 3.4.5.6.8.10 13.16.19.22.25 60 450 For water vapor, air, petroleum Product Y 5.6.8.10.13 16.19.22.25N 3.5.6.8.10.13 16.19.22.25 YS350 F, Y, N 3.5.6.8.10.13 16.19.22.25. 45 350 YS250 F, Y, N 3.5.6.8.10.13. 16.19.22.25 45 250 Table 5-2 Note: The shape code F means square, through the core or one to multi-layer braid; Y means round, with a twisted core in the middle, and one to multi-layer braid on the outside; N means twisted. Name, grade and specification (straight formula or square side length) Applicable ultimate pressure kgf/cm2 Applicable ultimate temperature (℃) Purpose Rubber asbestos packing XS450 3.4.5.6.8 10.13.16.19 22.25.28 60 450 Used for steam and petroleum products XS350 45 350 XS250 45 250 Table 5-3

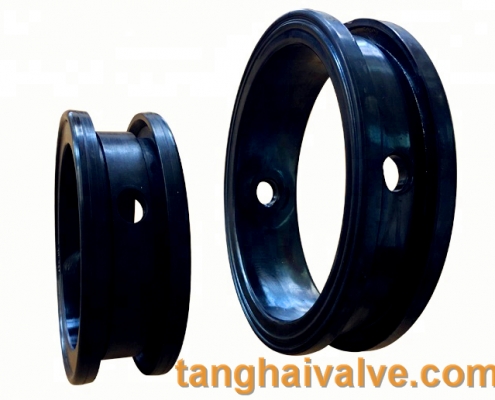

3. Gasket material:

The gasket is used to fill all the unevenness between the two joint surfaces (such as the sealing surface between the valve body and the valve cover) to prevent the medium from leaking between the joint surfaces. 1. Requirements for gaskets The gasket material has a certain degree of elasticity, plasticity and sufficient strength at working temperature to ensure sealing. At the same time, it must have good corrosion resistance. 2. Types and selection of gasket materials Gaskets can be divided into two types: soft and hard. The soft is generally non-metallic materials, such as cardboard, rubber, asbestos rubber sheet, and polytetrafluoroethylene. Hardness is generally metal material or metal-coated asbestos, metal and asbestos entangled, etc. There are many shapes of gaskets, including flat, round, oval, tooth-shaped, lens-shaped and other special shapes. Metal gaskets are generally made of 08, 10, 20 high-quality carbon steel and 1Cr13, 1Cr18Ni9 stainless steel, which require high machining accuracy and surface finish, and are suitable for high temperature and high pressure valves. Non-metallic gasket materials generally have good plasticity and can be sealed with less pressure. Suitable for low temperature and low pressure valves. The gasket material can be selected according to Table 5-4. Gasket material medium application range Pressure (Mpa) Temperature (℃) Thick cardboard water, oil ≤10 40 Oil-immersed cardboard water, oil ≤10 40 Rubber sheet water, air ≤6 50 Asbestos board steam, gas ≤6 450 poly Tetrafluoroethylene corrosive medium≤25 200 Rubber asbestos board XB-450 Water vapor, air, gas≤60 450XB-350 Water vapor, air, gas≤40 350XB-200 Water vapor, air, gas≤15 200 Oil-resistant rubber asbestos board oil Class 160 3008 steel and XB-450 filling steam 100 45008 steel and XB-350 filling steam 40 3501Cr13, 0Cr13 asbestos filling steam 100 60008 steel and oil-resistant rubber asbestos filling oil 100 350 copper water vapor, air 100 250 aluminum water vapor, air 64 35010 steel, 20 steel water steam, oil 200 4501Cr13 steam 200 5501Cr13Ni9 steam 200 600

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Valve material and valve standards-(4)-fastener material;

Valve material and valve standards-(5)-packing material;

Valve material and valve standards-(6)-gasket material;

The structure and characteristics of bellows gate valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.