Valve material and valve standards-(3)-sealing material

Section 2: Sealing surface material

The sealing surface is the most critical working surface of the valve. The quality of the sealing surface is related to the service life of the valve. Generally, the sealing surface material considers factors such as corrosion resistance, scratch resistance, erosion resistance, and oxidation resistance. Generally, sealing surface materials are divided into two categories:

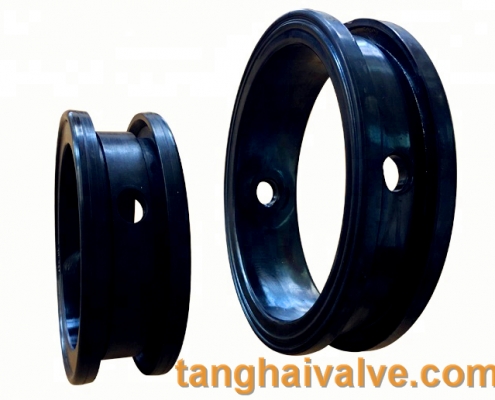

1. Soft materials

soft sealing marine valve, rubber sealing, valve seat parts

1. Rubber (including nitrile rubber, ethylene propylene rubber, fluorine rubber, etc.)

2. Plastics (polytetrafluoroethylene, nylon, etc.)

2. Hard sealing material

1. Copper alloy (for low pressure valve)

2. Chrome stainless steel (used for ordinary high and medium pressure valves)

3. Stellite alloy (used for high temperature and high pressure valves and strong corrosion valves)

4. Nickel-based alloy (used for corrosive media)

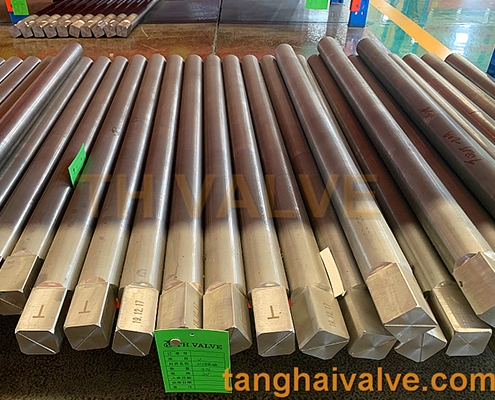

Section 3: Valve Stem Material

During the opening and closing of the valve, the valve stem bears tensile, compressive and torsional forces, and is in direct contact with the medium. At the same time, there is relative frictional movement with the packing. Therefore, the valve stem material must ensure sufficient strength at the specified temperature And impact toughness, a certain degree of corrosion resistance and abrasion resistance, and good manufacturability. Commonly used valve stem materials are as follows:

1. Carbon steel: For water with low temperature and medium temperature not exceeding 300°C, when steam

18 buttefly-valve-stem-shaft-parts-1

medium, A5 ordinary carbon steel is generally selected (now Q275, A3 is Q235)

2. Alloy steel: For medium pressure and high pressure, when the medium temperature does not exceed 450°C, 40Cr (chromium steel) is generally used when the medium temperature does not exceed 450°C. Water, the medium temperature does not exceed 540°C For steam and other media, 38CrMoAlA nitriding steel can be selected; for high-pressure steam media with a medium temperature not exceeding 570°C, 25Cr2MoVA chromium molybdenum vanadium steel is generally selected.

3. Stainless and acid-resistant steel: used for medium and high pressure, non-corrosive and weakly corrosive media with a medium temperature not exceeding 450°C. 1Cr13, 2Cr13, 3Cr13 chromium stainless steel can be selected; when used in corrosive media, it can be used Use Cr17Ni2, 1Cr18Ni9Ti, Cr18Ni12Mo2Ti, Cr18Ni12Mo3Ti and other stainless acid-resistant steels and PH15-7Mo precipitation hardening steels.

4. Heat-resistant steel: 4Cr10Si2Mo martensitic heat-resistant steel and 4Cr14Ni14W2Mo austenitic heat-resistant steel can be used for high-temperature valves whose medium temperature does not exceed 600°C.

Section 4: Valve Stem Nut Material

The stem nut directly bears the axial force of the stem during the opening and closing of the valve, so it must have a certain strength. At the same time, it and the valve stem are threaded transmission, which requires a small coefficient of friction, no rust and avoid seizure. The main materials are as follows:

1. Copper alloy: Copper alloy has a small friction coefficient and does not rust. It is one of the commonly used materials. For low pressure valves with Pg<1.6Mpa, ZHMn58-2-2 cast brass can be used.

2. Steel: When the working conditions do not allow the use of copper alloys, high-quality carbon steels such as 35, 40, 2Cr13, 1Cr18Ni9, Cr17Ni2 and other stainless and acid-resistant steels can be selected. The working conditions do not allow the following:

For electric valves, stem nuts with gua-shaped clutches require heat treatment to obtain high hardness or surface hardness.

When the working medium or the surrounding environment is not suitable for copper alloys, such as ammonia medium that is corrosive to copper.

When selecting steel stem nuts, pay special attention to thread seizure.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Valve material and valve standards-(4)-fastener material;

What is the material of the butterfly valve stem?

What is the material of Bolts and nuts of Valve Stem?

What is the material of the main parts of the butterfly valve?-(2)

tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.