Y type ball check valves’ work theory, construction feature, advantage

1. Overview of ball check valve:

Ball type check valve is widely used in petroleum, chemical and electric heating boilers and other devices. It is

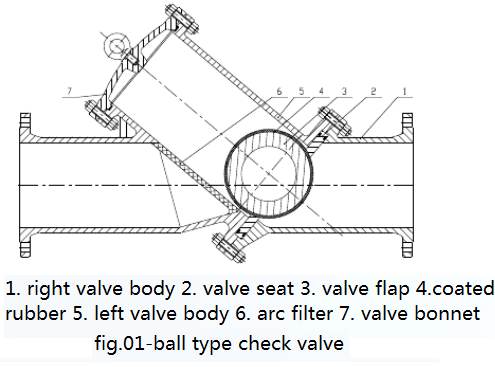

fig.01-ball check valve drawing

mainly used to prevent the reverse flow of the medium in the pipeline and protect the safe operation of the equipment. It is an ideal non-return device for pipelines. However, the current common check valve structures include swing type and lift type. Because these common check valves have problems such as easy sticking, poor sealing, difficult to repair, and may cause serious shutdown when they close by themselves. The valve water hammer phenomenon, and the water hammer pressure far exceeds the system working pressure, so the system safety may be endangered. Therefore, in addition to meeting the basic requirements of flow, the design of the check valve is the most important thing is the size of the flow resistance, whether there is leakage or vortex, which is related to energy consumption, and at the same time affects the level of production cost and product competitiveness. This new ball check valve is designed based on the theory of reducing flow resistance and eliminating water hammer.

2. Working principle of ball check valve:

The ball check valve shown in Figure 1 includes a valve body, a valve seat 2, a valve cover 7, and a valve disc. The valve body is composed of a left valve body 5 and a right valve body 1. The right valve body is the medium inlet end, and the left valve body The body is the outlet end of the medium. The valve seat 2 is installed between the left valve body 5 and the right valve body 1. The valve disc is a ball 3, and the sealing surface of the valve seat 2 is a spherical surface that cooperates with the surface of the ball 3. The left valve body is composed of a fluid channel and a ball track. The centerline of the sphere track forms an acute angle with the centerline of the fluid channel, and the angle design of the acute angle is determined according to the flexible rise and fall of the valve flap 3 in the sphere track. An arc-shaped filter screen 6 is arranged at the intersecting line of the fluid channel and the sphere orbit. The arc-shaped filter screen 6 has the same curvature as the inner circular wall of the sphere orbit, so that the inner arc of the arc-shaped filter screen 6 and the inner circular wall of the sphere orbit are formed The integral inner cylindrical surface constitutes a smooth rolling passage for the valve flap 3, which does not affect the flow of the medium, and enables the valve flap 3 to roll flexibly. This valve uses media thrust and disc gravity to automatically control the rolling position of the ball in the ball track. When the medium flows in the forward direction, the media thrust pushes the disc to the upper end of the ball track. When the positive thrust of the medium disappears, the disc moves from the ball track. The upper end rolls off and fits the valve seat sealingly, which has the advantages of simple structure, the ball is not easy to be stuck in the ball track, the sealing reliability is good, and the water hammer is small.

3. Structural features of ball check valve:

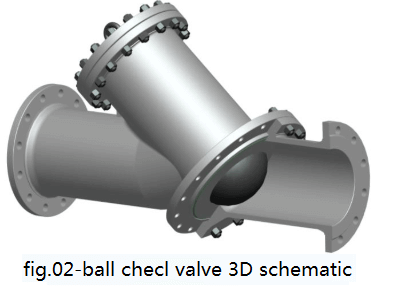

fig.2-ball check valve 3D schematic

The ball check valve has no transmission parts in structure and has a free opening and closing structure, so there is no wear of the shaft and sleeve. The valve flap automatically rotates in the ball orbit, and the sealing surface is always updated, and there is no fixed wear point. The ball surface wears evenly during the working process, and always maintains a high shape accuracy. The use performance will not decrease with the passage of time, which improves the service life of the seal. The surface of the valve disc is lined with rubber, and the dimensional accuracy and surface roughness of the ball can be controlled by the rubber lined mold. The processing accuracy of the ball is reduced, and it can be reused, which reduces the cost of the disc. The surface rubber of the steel ball will elastically deform, can absorb and dampen vibration, and play a certain buffering effect. The low density of rubber makes the inertia of the disc movement small and the movement is sensitive. The sphere adopts a hollow structure and is light in weight, which reduces the impact force of the valve disc on the valve seat when it is closed. The inner diameter of the sphere track is designed to be larger than the pipe diameter of the corresponding flange, which increases the flow cross section, reduces the medium resistance and reduces the pressure. When the sealing structure is designed according to the corresponding flange, the working pressure is from vacuum to medium pressure. Under the premise of not being restricted by installation conditions, the ball check valve can be installed horizontally or vertically. Moreover, the valve is easy to maintain in the pipeline, and only needs to replace the lower disc.

4. Conclusion of ball check valve:

In accordance with DIN EN 12266 “Pressure Test of Valves” and corporate standards, the series of ball check valves have been inspected and tested. As a result of the test, the technical performance parameters fully meet the design requirements. The application of this valve improves the safety factor of other equipment on the pipeline, with low flow resistance, flexible opening and closing, and good sealing performance, which is welcomed by users. This valve is also equipped with a curved filter screen to purify the medium. One valve has multiple functions, meeting customers’ multi-functional requirements, and greatly reducing customer costs.

Related news /knowledge:

Classification and characteristics of ball valve;

Types and classifications of ball valves;

What is a ball valve?;

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.