High platform ball valve and ordinary ball valve

The difference and selection of high platform ball valve and ordinary ball valve

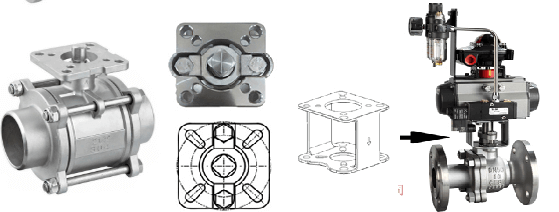

High platform ball valve, the so-called high platform means that the ball valve adopts the ISO5211 manufacturing standard. A square or round flange and the ball valve are cast into one piece, and the end of the platform is higher than the outer edges of the flanges at both ends, which is not only conducive to easy installation Pneumatic actuators, electric actuators and other actuators can greatly improve the stability between the valve and the actuator, and the appearance is more beautiful and refined. The high platform usually called york or bracket.

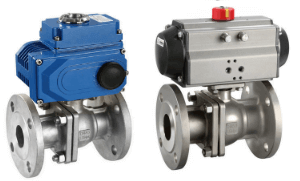

Pneumatic electric high platform ball valve

Electric high platform ball valve Pneumatic high platform ball valve

The high platform ball valve is an evolution of the conventional ordinary bracket ball valve. The difference between it and the ordinary ball valve is that it can be directly connected to the drive actuator without installing a connecting bracket, while the ordinary ball valve requires the bracket to be installed before the actuator can be installed. . In addition to avoiding additional bracket installation, because it is installed directly on the platform, this greatly improves the stability between the actuator and the ball valve.

The advantage of the high platform ball valve is that it can directly install pneumatic or electric actuators on its own platform, while ordinary ball valves require additional valve connections. This may occur due to loose brackets or excessive coupling gaps. As a result, the valve is affected in use, but the high platform ball valve will not have this problem. Its performance is very stable during operation.

Schematic diagram of high platform ball valve

In the selection of high-platform ball valves and ordinary ball valves, the internal structure of the high-platform ball valve is still the principle of opening and closing, which is consistent with the ordinary ball valve. In addition to the advantages described above, when the medium temperature is relatively high, it needs to be adopted The connection bracket is to protect the normal use of the actuator and prevent the heat transfer of the medium from causing the actuator to be unusable.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Pneumatic ball valve-with high platform vs with bracket;

Ball valve model preparation method/code name establishment;

Comparison of bellows globe valve and ordinary globe valve;

bellows globe valve vs ordinary globe valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.