Butterfly Valve of Marine Valves(tanghai valve)

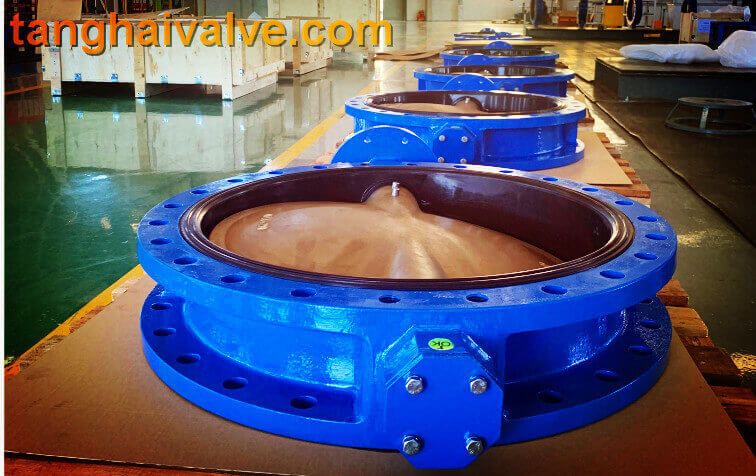

A butterfly valve used in marine applications, often referred to simply as a marine butterfly valve, is a critical component in ship systems for controlling the flow of fluids such as water, fuel, and various other liquids.

Here’s an overview Features:

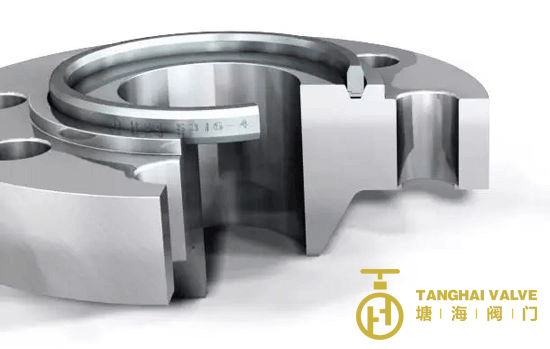

- corrosion Resistance: Marine environments expose valves to corrosive elements like saltwater. Hence, marine butterfly valves are typically made from materials such as bronze, stainless steel, or other corrosion-resistant alloys.

- Compact Design: Space is often limited aboard ships, so marine butterfly valves are designed to be compact and lightweight while still providing efficient flow control.

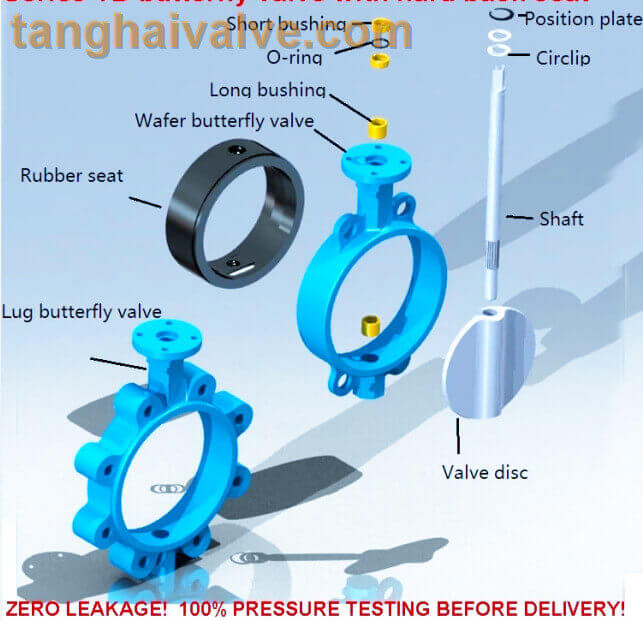

- Resilient Seating: Many marine butterfly valves feature resilient seating made of materials like EPDM or NBR, which offer excellent sealing properties and resistance to wear, corrosion, and chemicals.

- Bidirectional Sealing: Butterfly valves are inherently bidirectional, meaning they can effectively seal flow in both directions, allowing flexibility in installation and operation.

- Manual or Actuated Operation: Marine butterfly valves can be operated manually using a hand lever or wheel, or they can be equipped with pneumatic, electric, or hydraulic actuators for remote operation and automation.

Selection Considerations:

- Size and Pressure Rating: Choose a valve size and pressure rating suitable for the intended application and system requirements aboard the ship.

- Material Compatibility: Select materials compatible with the fluids being handled and resistant to corrosion in the marine environment.

- Sealing Material: Consider the type of sealing material based on temperature, pressure, and fluid properties to ensure reliable performance and longevity.

- Operation Type: Determine whether manual or actuated operation is preferable based on accessibility, control requirements, and automation needs.

- Compliance and Certification**: Ensure the selected valve meets relevant industry standards and certifications for marine applications, such as those from classification societies like DNV, ABS, or Lloyd’s Register.

Usage:

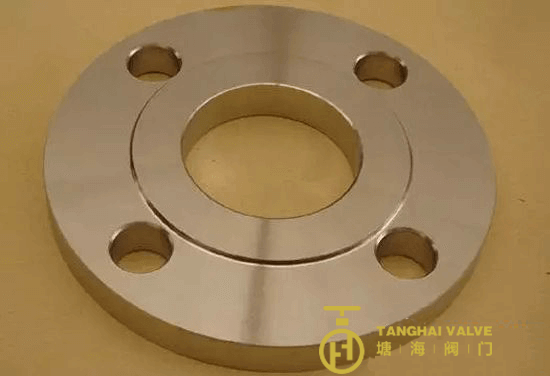

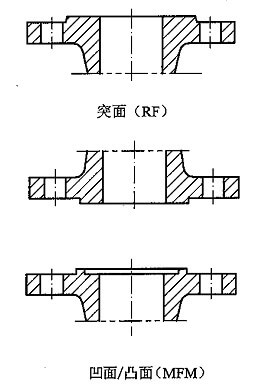

- Installation: Install the marine butterfly valve correctly according to manufacturer specifications, ensuring proper alignment, bolt torquing, and gasket sealing between flanges.

- Operation: Operate the valve using the designated controls, whether manual or actuated, following established procedures for opening, closing, and adjusting flow rates as needed.

- Maintenance: Implement a regular maintenance schedule to inspect, clean, lubricate, and replace components as necessary to ensure optimal performance and reliability.

- Monitoring: Periodically monitor the valve’s operation and condition for signs of leakage, wear, or malfunction, and take corrective action as required to prevent downtime or safety hazards.

- Emergency Response: Establish protocols for responding to valve failures, leaks, or other emergencies, including shutdown procedures, isolation measures, and contingency plans to mitigate risks and minimize disruptions. By considering these factors and adhering to best practices for selection, installation, operation, and maintenance, marine butterfly valves can effectively control flow and contribute to the safe and efficient operation of ship systems.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.