Fluorine-lined valve instructions | Installation instructions

Fluorine-lined valve instructions | Installation instructions

1 The fluorine-lined valve flange cover cannot be opened at will. Unless it is ready to be connected to the pipeline, the PTFE flange surface may be bumped, scratched or deformed due to temperature differences and foreign objects, which may affect the sealing. If the cover is moved due to inspection needs, It is also necessary to quickly reset the cover plate after inspection to protect the PTFE flange surface.

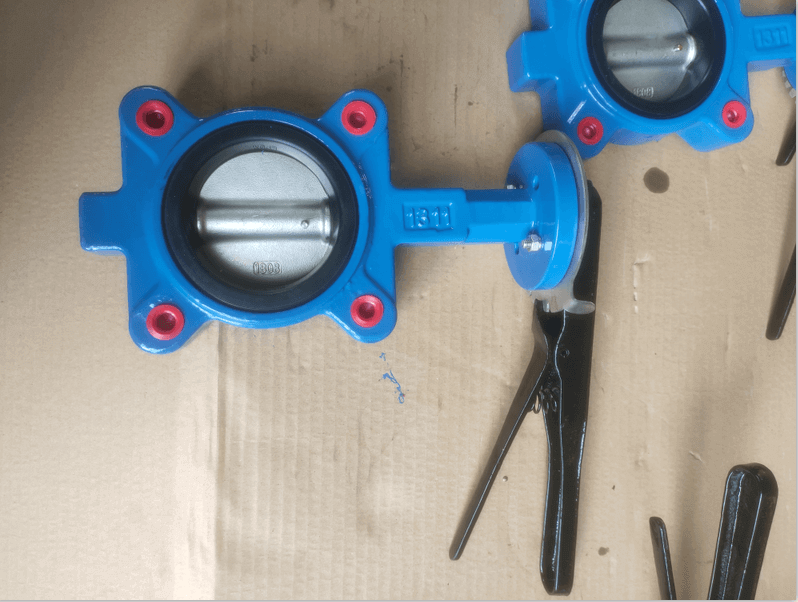

Fluorine lined butterfly valve-PTFE-WAFER (9)

2 When the fluorine-lined valve is connected to the pipeline, the gasket is generally no longer used alone, but when it is connected with the flange surface of dissimilar materials (metal surface, etc.), appropriate gaskets should be used to protect the PTFE flange surface.

3 During the use of the fluorine-lined valve, if a leak occurs at a higher temperature, the system temperature should be lowered to room temperature first, and then the cause should be investigated and repaired.

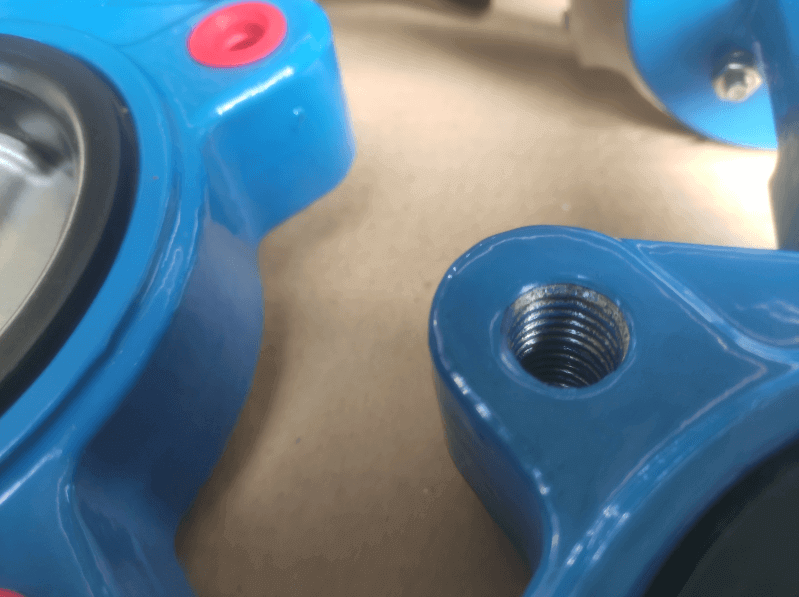

4 During installation, the flange nuts should be evenly tightened in the diagonal direction (symmetrically), and matched with appropriate torque: a If the flange sealing surface leaks and the leak location nut is locked, the leak location nut should be loosened at this time Half a circle, and then apply the same torque to the opposite side to lock it again; b If the above method still does not stop the leakage, check whether the PTFE flange surface has unevenness, indentation, scratches, and then it can be leveled with fine gauze paper or cloth. reconnect.

5 It is not allowed to do any high temperature welding work on the fluorine-lined valve to avoid permanent damage to the lining layer.

6 Fluorine-lined valves should be stored in a dry and ventilated room. Stacking is strictly prohibited.

7 Fluorine-lined valves after maintenance must be tested and qualified according to relevant standards before they can be installed.

8 When manually operating the fluorine-lined valve, it is not allowed to force the valve to be opened or closed with the help of other levers.

9 When installing fluorine-lined valves with directional requirements, pay attention to the flow of the medium in the direction indicated by the arrow on the valve body, and ensure convenient operation and maintenance.

10 The sealing pair of fluorine-lined valves stored for a long time should be in a slightly separated state to avoid permanent deformation of the sealing surface under long-term pressure, which will affect the sealing performance and service life.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.