Concentric Type Butterfly valve with resilient seated

A concentric type butterfly valve with a resilient seat is a type of valve commonly used in various industries for flow control. Let’s break down its components:

Concentric Design: In this design, the centerline of the stem (the shaft that controls the opening and closing of the valve) is also the centerline of the disc (the “butterfly” part of the valve). This design allows for smooth flow regulation and minimal turbulence.

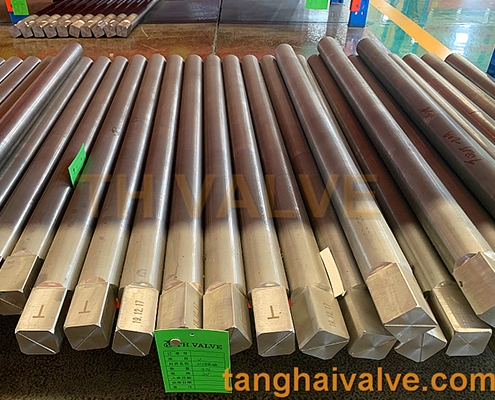

Butterfly Valve: This valve uses a disc as the flow control element. The disc is mounted on a shaft in the center of the valve’s body. When the valve is open, the disc is parallel to the flow, allowing fluid to pass through. When the valve is closed, the disc is perpendicular to the flow, blocking it.

Resilient Seat: The seat of the valve is the part where the disc makes contact when the valve is closed. Resilient seats are made from materials like EPDM (ethylene propylene diene monomer) or NBR (nitrile butadiene rubber). These materials are resilient, meaning they can deform slightly to ensure a tight seal when the valve is closed. Resilient seats also provide good resistance to wear and tear and are suitable for a wide range of operating temperatures.

In practical terms, a concentric type butterfly valve with a resilient seat is often used in applications where a tight shut-off is required, such as in water treatment plants, HVAC systems, and various industrial processes. The resilient seat ensures a reliable seal, and the concentric design allows for smooth operation and minimal pressure drop across the valve.

Tianjin Tanghai Valve Co., Ltd. is a professional marine valve manufacturer, including butterfly valve, check valve, gate /Knife gate valve. We have certificates:

CE, ISO, BV, DNV foundry and products approval. Now we have our own independent R & D, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services.

Please contact us if you need more support, please contact us freely: info@tanghaivalve.com.

We are committed to “Build a top valve enterprise; Be a reliable partner!”

Friends from all over the world are welcome to visit us for evaluation, guidance, and orders!

Selection Considerations:

Selection Considerations: Usage:

Usage:

tanghaivalve.com

tanghaivalve.com tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.