Difference between soft seal butterfly valve and hard seal butterfly valve

The difference between soft seal butterfly valve and hard seal butterfly valve:

A butterfly valve hard seal refers to a “hard seal” in which both sides of the seal pair are made of metal materials or other harder materials. This kind of seal has poor

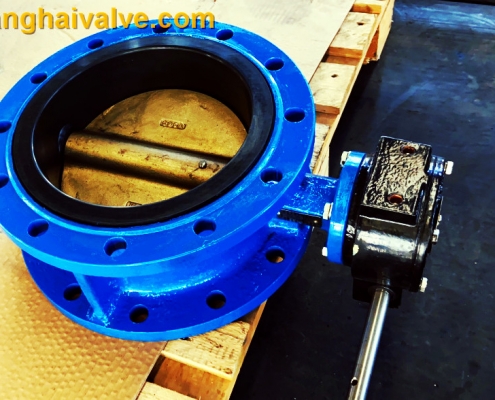

ductile iron, DI, butterfly valve, manufacturer, center line, TH valve

sealing performance, but high temperature resistance, wear resistance, and good mechanical properties. For example, : Steel + Steel; Steel + Copper; Steel + Graphite; Steel + Alloy Steel; (The steel here may also be cast iron, cast steel, alloy steel or surfacing, sprayed alloy).

The soft seal seal pair is made of metal materials on one side and elastic non-metallic materials on the other side. It is called “soft seal”. This kind of seal has better sealing performance, but it is not resistant to high temperatures, easy to wear, and mechanical Poor performance. Such as: steel + rubber; steel + tetrafluoropolyethylene; etc. The soft sealing seat is made of non-metallic materials with certain strength, hardness and temperature resistance, with good sealing performance, zero leakage, but life And the adaptability to temperature is relatively poor. The hard seal is made of metal, and the sealing performance is relatively poor, although some manufacturers claim that it can achieve zero leakage. The soft seal cannot meet the process requirements for some corrosive materials, and the hard seal can solve it! These two types of seals can complement each other. In terms of tightness, the soft seal is relatively good, but now the tightness of the hard seal can also meet the corresponding requirements! The advantage of the soft seal is good sealing performance, but the disadvantage is that it is easy to age, wear, and has a short service life. The hard seal has a long service life, but the tightness is relatively worse than that of the soft seal.

The main differences in its structure are as follows

1. The difference in structure

Soft seal butterfly valves are mostly centerline type, and hard seals are mostly single eccentric, double eccentric, and triple eccentric butterfly valves.

2. Temperature resistance

The soft seal is used in normal temperature environment. Hard seal can be used in low temperature, normal temperature, high temperature and other environments

3. Pressure

Soft seal low pressure-normal pressure, hard seal can also be used in medium and high pressure conditions

4. Sealing performance: The soft sealing and triple eccentric hard sealing butterfly valves have better sealing performance. The triple eccentric butterfly valve can maintain good sealing under high pressure and high temperature environment.

In view of the above characteristics, the soft sealing butterfly valve is suitable for the two-way opening and closing and adjustment of ventilation and dust removal pipelines, water treatment, light industry, petroleum, chemical and other industries. Hard-sealed butterfly valves are mostly used in heating, gas, gas, oil, acid and alkali environments.

With the widespread use of butterfly valves, its features of convenient installation, convenient maintenance and simple structure become more and more obvious. Electric soft-sealed butterfly valves, pneumatic soft-sealed butterfly valves, hard-sealed butterfly valves, etc. have begun to replace electric gate valves and globe valves in more and more occasions.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Difference between Soft seal gate valve and hard seal gate valve

Installation instructions for ball valves

The chemical composition, characteristics and applications of rubbers

Detailed introduction of soft sealing butterfly valve-(3)

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.