Standards for Use of Marine Valves

Specifies dimensions for metal valves used in marine applications.

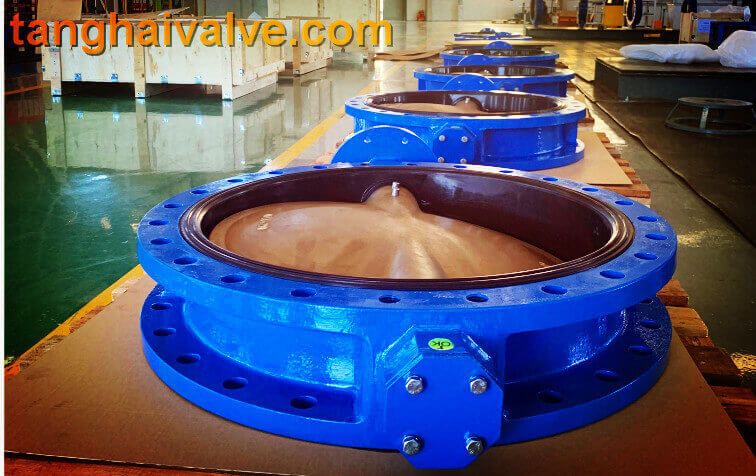

butterfuly valve manufacturer

Classification Societies

Classification societies provide additional guidelines and standards specific to marine applications. Some of the major classification societies include:

American Bureau of Shipping (ABS):

ABS Rules for Building and Classing Marine Vessels: Includes requirements for the design, construction, and testing of valves used in marine vessels.

Lloyd’s Register (LR):

Rules and Regulations for the Classification of Ships: Contains specific sections on the requirements for marine valves, including materials, design, and testing.

Bureau Veritas (BV):

Rules for the Classification of Steel Ships: Provides guidelines on the use of valves in marine applications, including specifications for materials and testing.

Det Norske Veritas (DNV):

DNV Rules for Classification of Ships: Outlines the requirements for valves used in marine systems, covering aspects such as design, materials, and performance testing.

National Standards

Different countries may have their own standards and regulations for marine valves. Some notable examples include:

ASTM (American Society for Testing and Materials):

ASTM F1199: Standard Specification for Ferrous Valves for Shipboard Use – Covers the requirements for ferrous valves used on ships.

BS (British Standards):

BS 6364: Valves for cryogenic service – Specifies the requirements for valves used in cryogenic applications, which can be relevant for certain marine applications.

Key Considerations for Marine Valves

Corrosion Resistance: Materials used for marine valves must be highly resistant to corrosion due to exposure to seawater and harsh marine environments.

Pressure and Temperature Ratings: Valves must be able to withstand the specific pressure and temperature conditions encountered in marine systems.

Safety and Reliability: Ensuring that valves operate reliably under the dynamic conditions of marine environments is crucial for safety.

Maintenance and Inspection: Valves should be designed for ease of maintenance and inspection, considering the limited access and challenging conditions on marine vessels.

Compliance and Certification: Marine valves should comply with relevant standards and regulations, and obtaining certification from recognized classification societies is often required.

By adhering to these standards and guidelines, marine valves can provide safe, reliable, and efficient performance in various marine applications, ensuring the safety and operational integrity of marine vessels and structures.

Tianjin Tanghai Valve Co., Ltd. is a professional marine valve manufacturer, including butterfly valve, check valve, gate /Knife gate valve. We have certificates: CE, ISO, BV, DNV foundry and products approval. Now we have our own independent R & D, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services. Below is our wafer butterfly valve of marine valves,if you need to check more information, please click here: https://www.tanghaivalve.com/wafer-type-butterfly-valve-th-btv-aw/

Please contact us if you need more support, please contact us freely: info@tanghaivalve.com.We are committed to “Build a top valve enterprise; Be a reliable partner!”Friends from all over the world are welcome to visit us for evaluation, guidance, and orders!

Selection Considerations:

Selection Considerations: Usage:

Usage:

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.