The difference between globe valve and gate valve

The difference between globe valve and gate valve, The difference between gate valve and globe valve

From the structure:

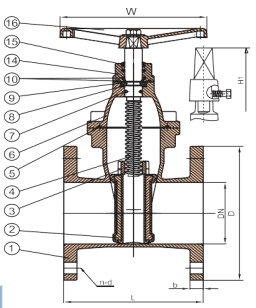

The length of the gate valve is shorter than that of the stop valve, and the height is higher than that of the stop valve. The installation of the rising stem gate valve should pay attention to the height. This should be paid attention to when the installation space is limited. The gate valve can be tightly closed with the sealing surface depending on the medium pressure, so as to achieve the effect of no leakage. When opening and closing, the valve core and the valve seat sealing surface are always in contact and rub against each other, so the sealing surface is easy to wear. When the gate valve is close to closing, the pressure difference between the front and rear of the pipeline is large, which makes the sealing surface wear more serious.

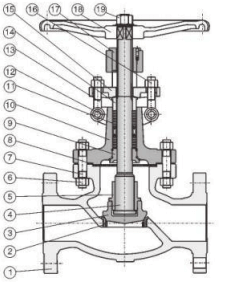

globe valve structure diagram

gate valve structure diagram

In principle:

The difference between the globe valve and the gate valve in principle is that the globe valve is a rising stem type, and the hand wheel rotates and rises together with the stem. In the gate valve, the hand wheel rotates and the valve stem moves upward. The flow rate is different, the gate valve is required to be fully open or fully closed, but the stop valve is not required. The shut-off valve has specified inlet and outlet directions; the gate valve has no inlet and outlet direction requirements.

Schematic diagram of gate valve Schematic diagram of globe valve

Explanation: The flow part of the gate valve is also the same as the straight pipe, but a gate is set in the pipe. If the gate is lifted up, the door will be fully opened, and the fluid of the stop valve will turn inside the valve. A 180-degree bend, usually the fluid enters from one side of the valve and after entering the valve, the fluid flows upward at a 90-degree angle, and then flows through the upper part of the valve body and then turns a 90-degree flow out, just as the fluid flows inside the valve. A cover is added to the upper outlet, the cover is closed and the door is closed, and the valve is opened when the cover is opened.

From the flow up:

The shut-off valve is low in and high out. From the outside, it is obvious that the pipeline is not on the horizontal line of one phase. The gate valve flow path is on a horizontal line. The stroke of the gate valve is larger than that of the stop valve.

globe cut-off valve working diagram-3D GIF animated presentation-flow direction

Explanation: From the perspective of flow resistance, the flow resistance of the gate valve is small when it is fully opened, and the flow resistance of the load stop valve is large. The flow resistance coefficient of ordinary gate valve is about 0.08~0.12, the opening and closing force is small, and the medium can flow in two directions. The flow resistance of ordinary globe valves is 3-5 times that of gate valves. When opening and closing, it needs to be forced to close to achieve the seal. The valve core of the stop valve does not contact the sealing surface when it is completely closed, so the wear of the sealing surface is very small. The stop valve that needs to add an actuator due to the main flow force should pay attention to the torque control mechanism Adjustment.

gate valve working diagram-3D GIF animated presentation-flow direction

From the installation:

1. The flow direction of the gate valve is the same when entering from both sides.

2. There are two ways to install the shut-off valve. One is that the medium can enter from below the valve core. The advantage is that the packing is not stressed when the valve is closed, which can prolong the service life of the packing and can be piped in front of the valve. Under pressure, the packing should be replaced; the disadvantage is that the driving torque of the valve is relatively large, which is about 1 times that of the upper flow, and the axial force on the valve stem is large, and the valve stem is easy to bend. Therefore, this method is generally only suitable for small-diameter stop valves (below DN50). For stop valves above DN200, the medium flows in from above. (The electric shut-off valve generally adopts the way that the medium enters from above.) The shortcoming of the medium entering method from above is just the opposite of that of the downward entering method.

From the sealing surface:

The sealing surface of the globe valve is a small trapezoidal side of the valve core (see the shape of the valve core for details). Once the valve core falls off, it is equivalent to closing the valve (if the pressure difference is large, of course the closing is not tight, but the anti-reverse effect is not bad). The gate valve is sealed by the side of the valve core gate plate, the sealing effect is not as good as the stop valve, and the valve core will not be closed like the stop valve when the valve core falls off.

You can check the detailed data sheet /specification /structure diagram /sizes /materials of

globe valve on:https://www.tanghaivalve.com/wp-content/uploads/2021/05/500-api-jis-globe-valve-cast-steel-forged-steel.pdf gate valve: https://www.tanghaivalve.com/wp-content/uploads/2021/05/301-data-sheet-gate-valve-th-valve.pdf

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

related news /knowledge:

The working principle and characteristics of the globe valve;

Classification of the globe valves-(1);

Pneumatic ball valve principle, structure and working principle;

The difference between globe valve and check valve;

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.