What Is C95400 Bronze Butterfly Valve Disc?

C95400 bronze is a commonly used aluminum bronze material for butterfly valve discs in marine and shipbuilding applications. It is well known for its excellent strength, corrosion resistance, and reliability in seawater environments.

Overview of C95400 Aluminum Bronze

C95400 is an aluminum bronze alloy primarily composed of copper, aluminum, and iron. This material offers a unique combination of high mechanical strength and outstanding resistance to corrosion, making it suitable for demanding marine conditions.

Compared with standard bronze materials, C95400 provides:

Higher tensile strength/Better wear resistance/Improved performance in seawater service

Why C95400 Is Used for Butterfly Valve Discs

The valve disc is the most critical component of a butterfly valve, as it is directly exposed to the fluid medium. In marine systems, seawater corrosion is one of the main challenges.

C95400 bronze butterfly valve discs are widely selected because:

They resist seawater corrosion and erosion

They maintain dimensional stability under pressure

They reduce the risk of pitting and surface degradation

These characteristics ensure smooth operation and reliable sealing performance throughout the valve’s service life.

Typical Marine Applications

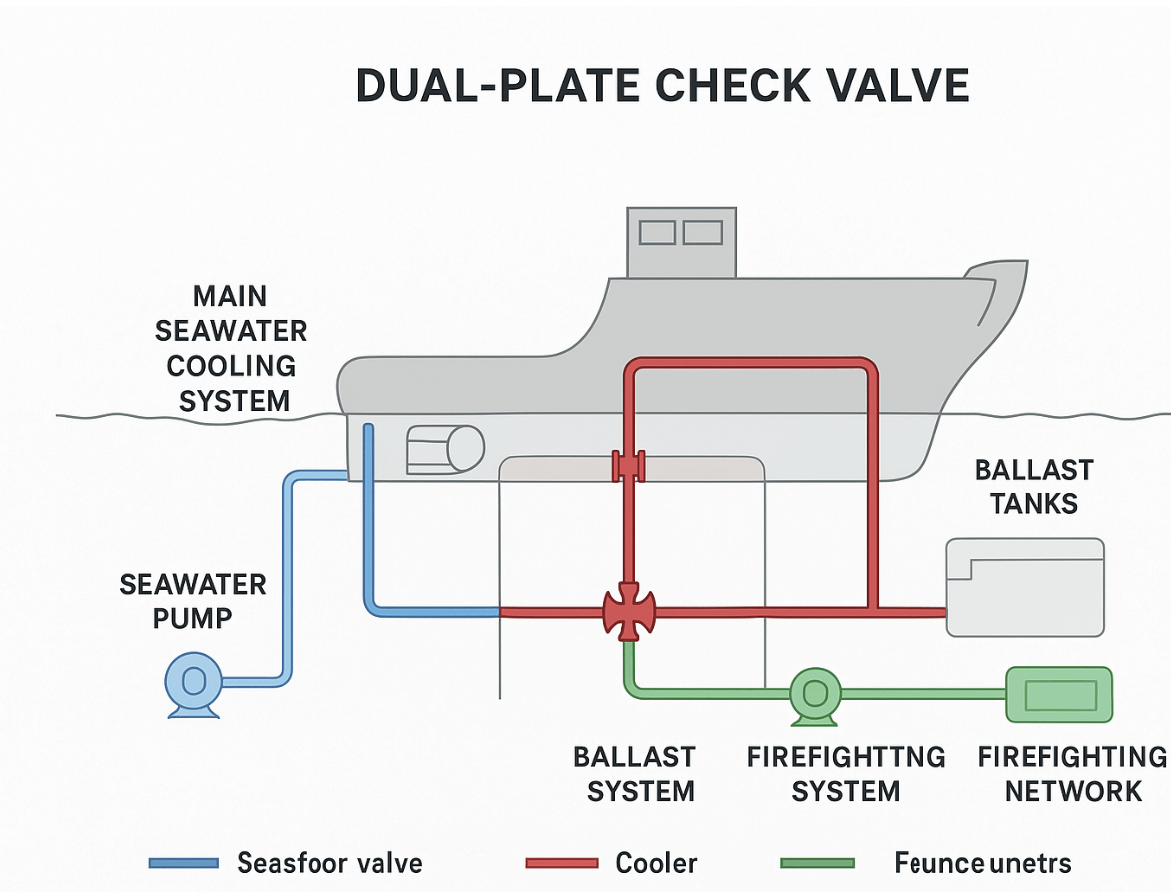

C95400 bronze butterfly valve discs are commonly used in:

Seawater cooling systems/Ballast water systems/Fire main systems/General marine piping systems

They are especially suitable for vessels operating in harsh offshore or long-term seawater environments.

Compliance with Marine Standards

Butterfly valves equipped with C95400 bronze discs can be manufactured to meet the technical requirements of major marine classification societies, including ABS, DNV, CCS, and LR, ensuring acceptance by shipowners and shipyards worldwide.

Conclusion

Due to its excellent corrosion resistance, mechanical strength, and proven performance in seawater applications, C95400 aluminum bronze remains one of the preferred materials for butterfly valve discs in marine systems.

Tianjin Tanghai Dongyang Valve Co., Ltd. manufactures marine butterfly valves with C95400 bronze discs, offering reliable solutions for ABS, DNV, CCS, and LR certified marine projects.

Tianjin Tanghai Valve Co., Ltd. is a professional marine valve manufacturer, including butterfly valve, check valve, gate /Knife gate valve. We have certificates: CE, ISO, BV, DNV foundry and products approval. Now we have our own independent R & D, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services. Below is our wafer butterfly valve of marine valves,if you need to check more information, please click here:https://www.tanghaivalve.com/double-flange-butterfly-valve-th-btv-df/

Please contact us if you need more support, please contact us freely: info@tanghaivalve.com.We are committed to “Build a top valve enterprise; Be a reliable partner!”Friends from all over the world are welcome to visit us for evaluation, guidance, and orders!

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.