The evolution of butterfly valve sealing structure: single eccentric butterfly valve, double eccentric butterfly valve and triple eccentric butterfly valve

Butterfly valves have been widely used due to their low cost, small size, light weight and long life. With the development of my country’s industry, various industries have more and more stringent requirements for the performance of equipment, especially in some gas pipelines or other hazardous material pipelines, the butterfly valve must achieve zero leakage, so the sealing structure design of the butterfly valve has always been important Research topics.

With the rapid development of modern industrial technology, butterfly valves are widely used in pipeline control systems, especially large-diameter pipeline control systems where other control valves are difficult to apply. Generally, the valve seat of the butterfly valve is a fixed type, and its materials are polymer and metal. The polymer valve seat is mainly suitable for working conditions with lower temperature. Although the metal seat butterfly valve can meet the higher temperature and pressure However, the elasticity of the metal valve seat is lower than that of the polymer valve seat, and the sealing performance is poor. The improvement of various performances of butterfly valves is closely related to its continuous improvement. For example, the development of butterfly valve sealing structure technology has successively experienced the evolution process of ordinary butterfly valve, single eccentric butterfly valve, double eccentric butterfly valve and triple eccentric butterfly valve.

Since the rotation center of the butterfly plate (that is, the center of the valve shaft) and the sealing section of the butterfly plate are set eccentrically according to a, the butterfly plate sealing surface gradually separates from the valve seat sealing surface during the opening process of the butterfly valve, and the butterfly plate rotates to 20°~25° , The sealing surface of the butterfly plate is completely separated from the sealing surface of the valve seat. When the valve is fully opened, a gap x is formed between the two sealing surfaces, so that the relative mechanical wear and extrusion between the two sealing surfaces of the butterfly valve is greatly reduced during the opening and closing process. Ensure the sealing of the butterfly valve.

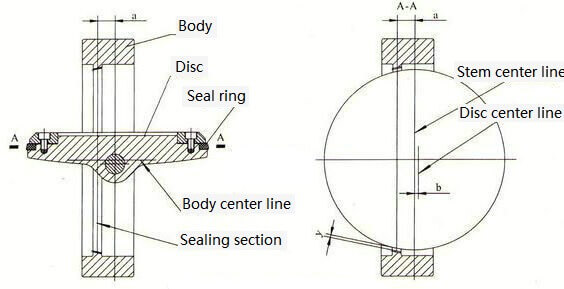

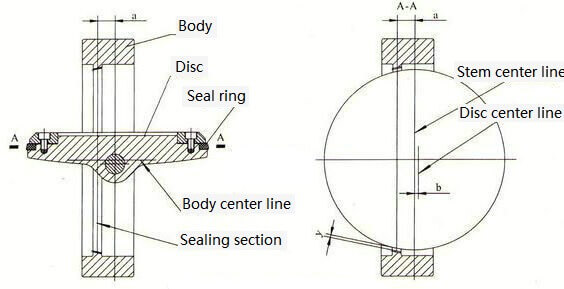

Since the rotation center of the butterfly plate (that is, the center of the valve shaft) and the center line of the valve body are offset by size b on the basis of the single eccentric butterfly valve, the sealing surface of the butterfly plate will be faster than the single eccentric sealing butterfly valve during the opening process of the butterfly valve. When the butterfly plate rotates to 8°~12°, the butterfly plate sealing surface is completely separated from the valve seat sealing. When it is fully opened, a larger gap y is formed between the two sealing surfaces. This type of butterfly valve is designed , Which greatly reduces the mechanical wear and extrusion deformation between the two sealing surfaces, and improves the sealing performance of the butterfly valve.

There are different types of eccentric sealing butterfly valves, and the fields of application and their respective characteristics are naturally different. But fundamentally speaking, the basic principles of eccentric sealing butterfly valves are similar.

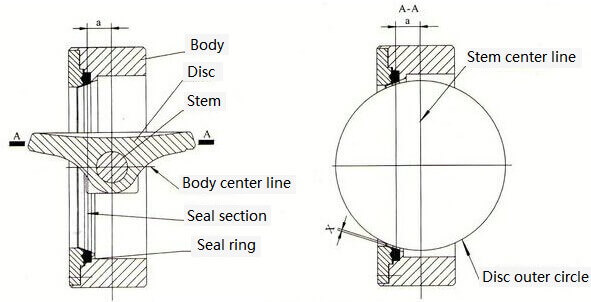

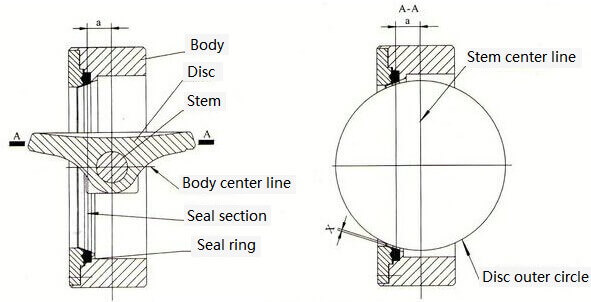

Structural characteristics of single eccentric butterfly valve:

single eccentric butterfly valve structure diagram

1. The center of rotation of the disc plate (that is, the center of the valve shaft) is located on the center line of the valve body, and an A-size offset is formed on the sealing section of the valve plate. The single eccentric butterfly valve is that the rotation center of the disc plate is on the center line of the valve body, and the valve plate deviates a distance from the sealing surface, which is suitable for soft sealing.

2. When the valve is closed, the valve seat and the sealing surface of the valve plate are in a relatively interference contact state. To achieve the seal, it is mainly by pressing the sealing ring to expand in the peripheral direction to produce the sealing specific pressure and the pipeline pressure against the valve plate. It can only be sealed in one direction because of the strong force.

3. When the valve is opened, the contact side of the valve plate and the valve seat is separated from the valve seat, and the other side is always two-point contact along the axial direction of the half circumference. Repeated opening and closing of the sealing ring is easy to be damaged, which affects the sealing performance. It is impossible to achieve a metal seal.

4. From a geometric point of view, it is obvious that X does not exist in the above figure, and in turn there is a certain amount of interference.

Structural features of double eccentric butterfly valve:

double eccentric butterfly valve structure diagram

The center of rotation of the valve plate (that is, the center of the valve shaft) forms an offset of dimension A on the sealing section of the valve plate, and forms an offset of dimension B with the center of the valve body.

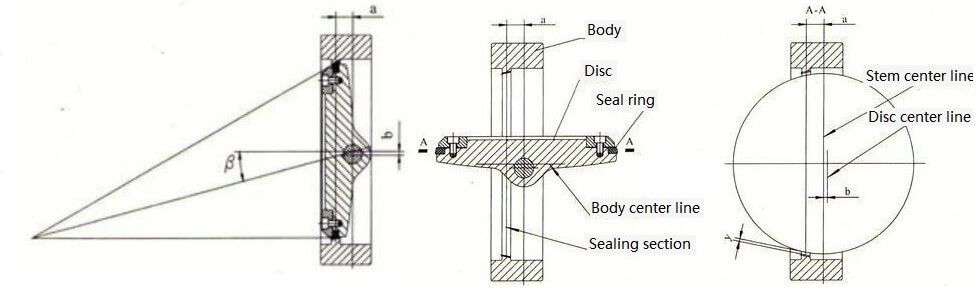

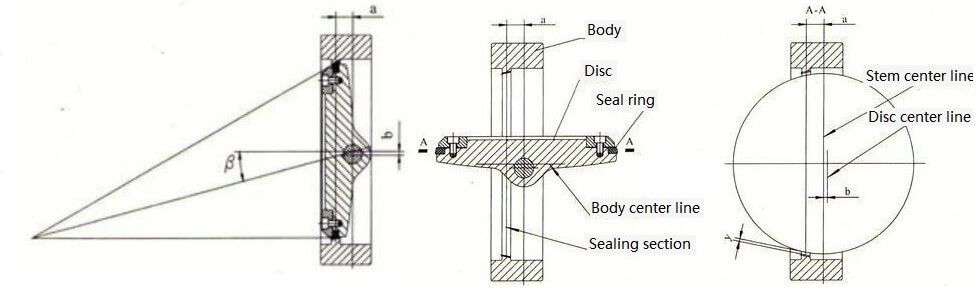

Since the center line of the valve seat and the center line of the valve body form a β angle offset on the basis of the double eccentric butterfly valve, the sealing surface of the butterfly plate immediately leaves the sealing surface of the valve seat at the moment of opening during the valve opening process of the butterfly valve. Only at the moment of closing does it contact and compress the seat sealing surface. When fully opened, a gap y is formed between the two sealing surfaces, which is the same as that of the double eccentric sealing butterfly valve. The design of this type of butterfly valve completely eliminates the mechanical wear and abrasion between the two sealing surfaces, making the butterfly valve more effective in its sealing performance and use. The life span has been greatly improved.

Structural features of triple eccentric butterfly valve:

triple eccentric butterfly valve structure diagram

The center of rotation of the valve plate (that is, the center of the valve shaft) forms an offset A on the sealing section of the valve plate, and an offset b from the center of the valve body; the centerline of the valve body sealing surface and the centerline of the valve seat (ie the centerline of the valve body) An angular offset of β is formed.

The uniqueness of the triple eccentric butterfly valve is that the stem shaft on which the butterfly plate is installed is a three-segment shaft structure. This three-segment shaft type valve stem has two shaft sections concentric, and the center line of the central shaft is deviated from the two ends of the axis by a center distance. , The butterfly plate is installed on the intermediate shaft section. Such an eccentric structure makes the butterfly plate a double eccentric shape when in the fully open position, and a single eccentric shape when the butterfly plate rotates to the closed position. Due to the effect of the eccentric shaft, when it is close to closing, the butterfly plate moves a distance into the sealing cone surface of the valve seat, and the butterfly plate matches the sealing surface of the valve seat to achieve reliable sealing performance.

Related Knowledge: Common Sense of Eccentric Butterfly Valve

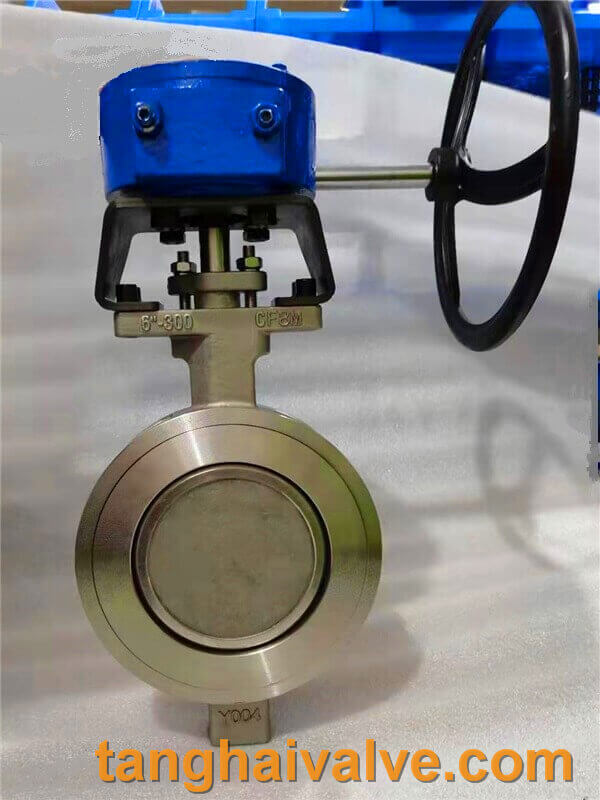

Related Products: Electric Triple Eccentric Butterfly Valve Pneumatic Triple Eccentric Butterfly Valve

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news /knowledge:

The sealing characteristics and principle of eccentric butterfly valve;

Classification and features of Eccentric butterfly valves;

Installation instructions of double eccentric butterfly valve;

Selection and application of eccentric butterfly valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.