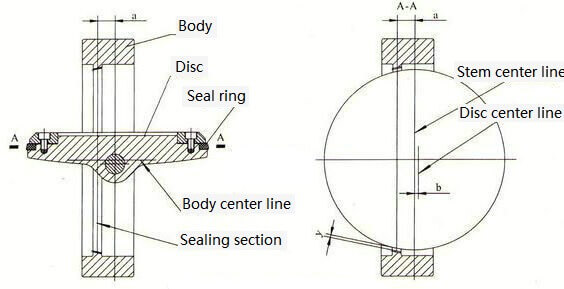

Structure diagram of double eccentric butterfly valve

Double eccentric butterfly valves are often referred to as high performance butterfly valves. On the basis of the single eccentric butterfly valve, the most widely used double eccentric butterfly valve is further improved and formed.

Structural features of double eccentric butterfly valve: The center of rotation of the valve plate (ie the center of the valve shaft) forms a dimension α offset with the valve plate sealing section, and a dimension b offset with the centerline of the valve body.

double eccentric butterfly valve structure diagram

Sealing principle of double eccentric butterfly valve: On the basis of the single eccentric sealing butterfly valve, the center of rotation of the valve plate (ie the center of the valve shaft) is offset by a dimension b with the center line of the valve body. When the double eccentric sealing butterfly valve is in a fully open state, The valve plate sealing surface will be completely separated from the valve seat sealing surface, and a gap y larger than the X gap in the single eccentric sealing butterfly valve is formed between the valve plate sealing surface and the valve seat sealing surface, thereby reducing the opening and closing of the valve plate. Mechanical wear and abrasion between the two sealing surfaces of the butterfly valve seal pair.

high performance-double eccentric-butterlfy valve-wafer-lug-flanged (6)

In the usual design, when the valve plate is rotated from 0° to 8° to 12°, the sealing surface of the valve plate can be completely separated from the sealing surface of the valve seat, so that during the opening and closing process of the butterfly valve, the sealing surface between the valve plate and the valve seat is separated. Compared with mechanical wear, the extrusion angle stroke is shorter, so that the mechanical wear and extrusion deformation are further reduced, and the sealing performance of the butterfly valve is further improved.

The main reasons for the failure of the sealing performance of the double eccentric butterfly valve sealing pair

① During the opening and closing process of the butterfly valve, when the valve plate rotates and squeezes the elastic soft valve seat, the valve plate and the valve seat are mechanically worn and scratched;

②After the valve plate squeezes the elastic valve seat, the elastic valve seat or the elastic layer of the valve plate will produce permanent plastic deformation, cold flow, elastic failure, etc.;

③The material of the elastic valve seat or the elastic layer of the valve plate is aging and failing, etc.;

④ Medium cavitation and erosion of the sealing surface.

Features of double eccentric butterfly valve

①The structure is more complicated than the single eccentric sealing butterfly valve, and the cost is slightly higher;

②The sealing performance is better than that of the single eccentric sealing butterfly valve;

③The service life is longer than that of the single eccentric sealing butterfly valve, and the operating pressure is also higher.

Difference: Double eccentric butterfly valve can use metal seat, which improves the application of butterfly valve in high temperature field. However, because its sealing principle is a positional sealing structure, that is, the sealing surface of the disc and the valve seat is in line contact, and the elastic deformation caused by the disc extrusion of the valve seat produces a sealing effect, so it has high requirements for the closing position (especially metal Valve seat), low pressure bearing capacity, which is why traditionally people think that butterfly valves are not resistant to high pressure and have large leakage.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of double eccentric butterfly valve:

Related news/knowledge:

Electric ball valve-metal seated vs soft-seated type

The sealing characteristics and principle of eccentric butterfly valve

Classification and features of Eccentric butterfly valves

Application of double eccentric butterfly valve and triple eccentric butterfly valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.