DNV Certification in Marine Butterfly Valves

DNV certification plays a vital role in marine butterfly valves, signifying that the product complies with the standards set by Det Norske Veritas (DNV, formerly DNV-GL). It is a key requirement for entering the international shipbuilding and offshore engineering markets.

1. What is DNV Certification?

DNV (Det Norske Veritas) is a world-leading classification society and risk management organization.

DNV certification is a third-party verification that a product meets DNV’s classification standards in terms of design, materials, manufacturing, testing, and quality control.

It is widely applied to ships, offshore structures, and energy equipment that demand high reliability and safety.

2. DNV Requirements for Marine Butterfly Valves

In the field of marine butterfly valves, DNV certification involves the following aspects:

1. Product Design and Drawing Approval

Valve designs must be submitted for review by DNV, including:

Structural drawings

Material specifications

Working pressure

Temperature range

Sealing structure and configuration

2. Material Certification

All pressure-bearing parts must use DNV-approved materials.

Material certificates conforming to EN 10204 3.1 or 3.2 are usually required.

3. Inspection of Castings or Forgings

DNV requires NDT (non-destructive testing) on valve bodies and discs, including:

Ultrasonic testing (UT)

Radiographic testing (RT)

Magnetic particle testing (MT) or dye penetrant testing (PT)

These inspections must be witnessed or reviewed by a DNV surveyor.

4. Performance Testing

Valves must undergo:

Shell pressure tests

Leakage/sealing tests

Typically carried out under the supervision of a DNV inspector.

For specific applications, additional tests may be required:

Low-temperature impact test

Fire safety test

Corrosion resistance tests (e.g., NACE standards)

5. Manufacturing Supervision and Final Acceptance

DNV monitors the manufacturing process.

A DNV-signed Product Certificate must be issued upon final acceptance.

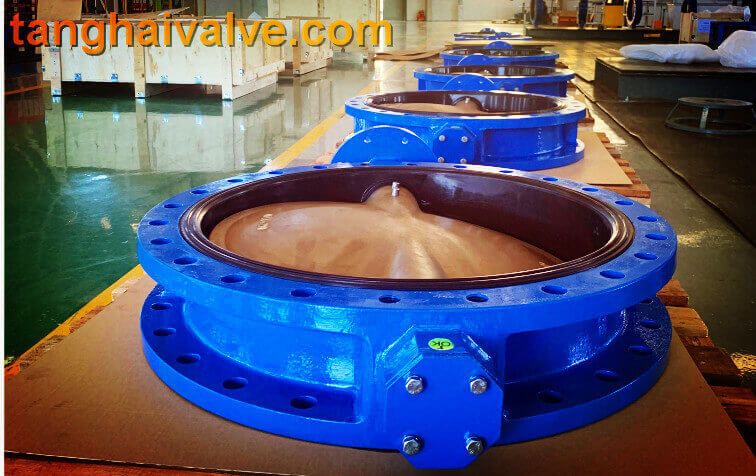

3. Common Applications of DNV-Certified Marine Butterfly Valves

Onboard Ship Systems:

Seawater cooling systems

Ballast water systems

Fire-fighting pipelines

Offshore Platforms:

Living quarters

Oil & gas transfer pipelines

LNG and Liquid Cargo Ships:

Cryogenic butterfly valves

Bi-directional sealing butterfly valves

4. Importance of DNV Certification for Export

DNV certification is a passport to major global markets such as:

Europe, Norway, Germany, the Netherlands, Singapore, Japan, etc.

Many renowned shipyards (e.g., Hyundai, Samsung Heavy Industries, Fincantieri) require valves to be certified by DNV or other major classification societies such as ABS, BV, or LR.

5. Recommended Information for Your Promotion

If you are involved in the casting of valve bodies, discs, or shafts, you can include the following statement in your promotional materials:

Our marine butterfly valve parts (valve body, disc, and shaft) are made from DNV-approved materials and produced under ISO 9001 quality control. We support our clients to pass DNV product certification through strict casting quality and mechanical property assurance.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.