Valve Parameters

- Nominal Diameter

The nominal diameter (DN) is a numerical designation used to define the size of all piping system components, distinguishing it from those parts that are designated by thread or outside diameter.

Another method for specifying valve sizes is the American system, which uses inches as the unit of measurement. For example, a DN50 valve corresponds to a 2-inch valve.

2.Rounded Numbers

All piping system components with the same nominal pressure (PN) value and the same nominal diameter (DN) have the same connection dimensions that correspond to the type of end connection. In China, when referring to nominal pressure, the unit of measurement is usually specified for clarity and is expressed as “MPa.” In countries like the UK and the US, although the concept of nominal pressure has been included in relevant standards, the imperial unit of pounds per square inch (psi) is still used in practice.

Because the reference temperature for nominal pressure and the pound system differs, there is no strict correlation between them. A general correspondence between them can be found in the table below. The Japanese standard includes a “K” system, such as 10K, 20K, 40K, etc. This pressure rating concept is similar to the pound system in imperial units, but the unit of measurement is metric. The relationship between the “K” rating and the pound system can be found in the table below.

Pressure markings are indicated by “PN” followed by a pressure value (in MPa). For example, PN1.0 indicates a valve with a nominal pressure of 1.0 MPa. However, in everyday use, it is common to refer to a PN10 valve as a 1.0 MPa valve, which is also referred to as a 10 bar/10 kg valve.

- 3. Common Unit Conversion Relationships

1 inch = 25.4 mm

1 MPa = 10 kgf/cm² (kilogram-force) = 10 bar

1 psi = 0.0069 MPa

1 ksi = 6.9 MPa

Psi: pounds per square inch

kgf/cm²: kilogram-force per square centimeter

Bar: bar

Fahrenheit to Celsius Conversion:

°C = (℉ – 32) * 5/9

Celsius to Fahrenheit Conversion:

℉ = ℃ * 9/5 + 32

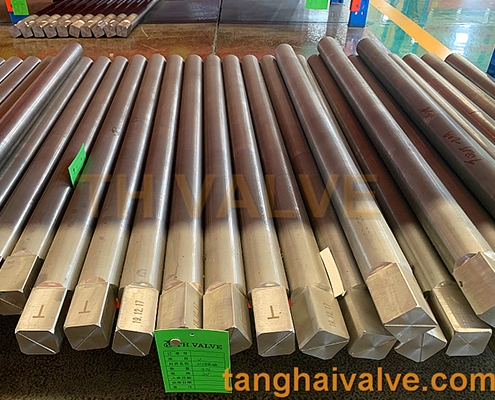

Tianjin Tanghai Valve Co., Ltd. is a professional marine valve manufacturer, including butterfly valve, check valve, gate /Knife gate valve. We have certificates: CE, ISO, BV, DNV foundry and products approval. Now we have our own independent R & D, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services. Below is our wafer butterfly valve of marine valves,if you need to check more information, please click here: https://www.tanghaivalve.com/wafer-type-butterfly-valve-th-btv-aw/

Please contact us if you need more support, please contact us freely: info@tanghaivalve.com.We are committed to “Build a top valve enterprise; Be a reliable partner!”Friends from all over the world are welcome to visit us for evaluation, guidance, and orders!

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.