Classification of valve

There are many types of valves, and they can be classified in various ways.

- Classification by automation and actuation

Automatic Valves: These valves operate automatically relying on the medium (liquid, gas, steam, etc.) itself. Examples include safety valves, check valves, pressure reducing valves, and automatic exhaust valves.

Actuated Valves: These valves are operated manually, electrically, hydraulically, or pneumatically. Examples include butterfly valves, gate valves, and ball valves.

II.Classification by purpose and function

Shut-off Valves: Primarily used to stop or start the flow of the medium. This includes gate valves, globe valves, plug valves, ball valves, butterfly valves, etc.

Regulating Valves: Primarily used to regulate the flow, pressure, etc., of the medium. This includes control valves, throttle valves, pressure reducing valves, etc.

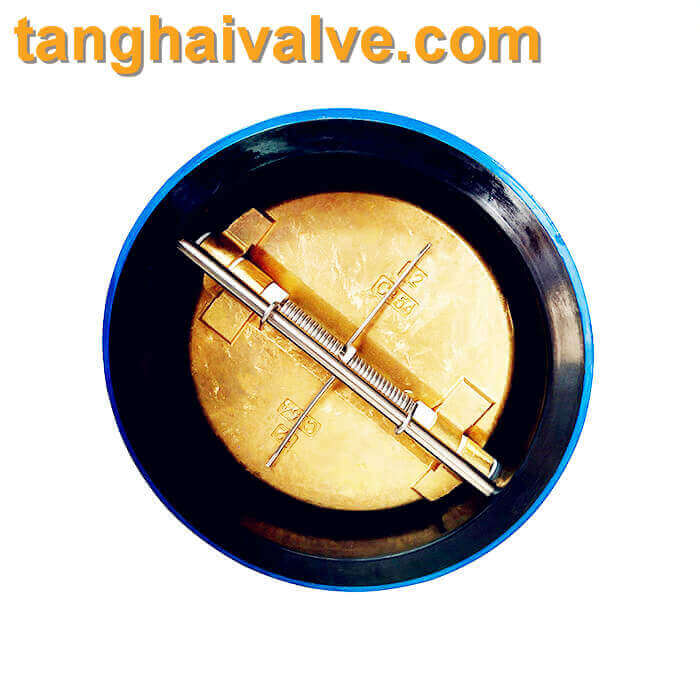

Check Valves: Used to prevent the backflow of the medium. This includes various types of check valves.

Diverting Valves: Used to distribute, separate, or mix the medium. This includes various types of distribution valves, three-way valves, and steam traps.

Safety Valves: Used for overpressure safety protection, releasing excess medium to prevent pressure from exceeding the specified value. Examples include safety valves.

Multi-function Valves: Used to replace two, three, or more types of valves, such as globe check valves, check ball valves, etc.

Other Special Valves: Examples include drain valves, pigging valves, etc.

III. Classification by main parameters

1, Classification by nominal diameter The nominal diameter is a rounded integer value used as a convenient reference to indicate the valve size. It is an approximate value rather than an exact measurement. The nominal diameter is marked with the letters “DN” (nominal diameter) followed by a value in millimeters. For example, a valve with a nominal diameter of 50 millimeters is marked as DN50.

- Small diameter valves: Valves with DN≤40mm

- Medium diameter valves: Valves with DN50-DN300mm

- Large diameter valves: Valves with DN350-DN1200mm (4) Extra-large diameter valves: Valves with DN≥1400mm

2, Classification by pressure Nominal pressure refers to the design-specified pressure related to the mechanical strength of the pipeline components. The pressure is marked with “PN” followed by a pressure value (MPa). For example, PN1.0 indicates a valve with a nominal pressure of 1.0 MPa. (1) Vacuum valves: Valves with a working pressure lower than standard atmospheric pressure. (2) Low-pressure valves: Valves with a nominal pressure of PN<1.6 MPa. (3) Medium-pressure valves: Valves with a nominal pressure of PN 2.5–6.4 MPa. (4) High-pressure valves: Valves with a nominal pressure of PN 10.0–80.0 MPa. (5) Ultra-high-pressure valves: Valves with a nominal pressure of PN≥100 MPa.

3, Classification by working temperature of the medium (1) High-temperature valves: Valves with t > 450℃ (2) Medium-temperature valves: Valves with 120℃ ≤ t < 450℃ (3) Normal-temperature valves: Valves with -40℃ ≤ t < 120℃ (4) Low-temperature valves: Valves with -100℃ ≤ t < -40℃ (5) Ultra-low-temperature valves: Valves with t < -100℃

4, Classification by valve body material (1) Non-metallic material valves: Such as ceramic valves, fiberglass valves, plastic valves (2) Metallic material valves: Such as copper alloy valves, Monel alloy valves, cast iron valves, carbon steel valves, alloy steel valves (3) Metal body lined valves: Such as lead-lined valves, plastic-lined valves, enamel-lined valves.

5, Classification by connection method to the pipeline (1) Flange connection valves: Valves with flanges on the body, connected to the pipeline using flanges. (2) Threaded connection valves: Valves with threads on the body, connected to the pipeline using threads. (3) Welded connection valves: Valves with weld ends on the body, connected to the pipeline using welding. (4) Clamp connection valves: Valves with clamps on the body, connected to the pipeline using clamps. (5) Ferrule connection valves: Valves connected to the pipeline using ferrules.

III. Common Classification This classification method is based on principle, function, and structure and is the most commonly used classification method domestically and internationally. It generally includes gate valves, globe valves, plug valves, ball valves, butterfly valves, diaphragm valves, check valves, throttle valves, safety valves, pressure reducing valves, steam traps, and control valves.

Tianjin Tanghai Valve Co., Ltd. is a professional marine valve manufacturer, including butterfly valve, check valve, gate /Knife gate valve. We have certificates: CE, ISO, BV, DNV foundry and products approval. Now we have our own independent R & D, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services. Below is our wafer butterfly valve of marine valves,if you need to check more information, please click here: https://www.tanghaivalve.com/wafer-type-butterfly-valve-th-btv-aw/

Please contact us if you need more support, please contact us freely: info@tanghaivalve.com.We are committed to “Build a top valve enterprise; Be a reliable partner!”Friends from all over the world are welcome to visit us for evaluation, guidance, and orders!

Key Features of Double Plate Check Valves

Key Features of Double Plate Check Valves Advantages in Marine Applications

Advantages in Marine Applications

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.