Valve seal (ring) material usage range comparison table

The selection of valve sealing material is determined according to the operating conditions of the valve, such as: pipeline medium, temperature range (high and low temperature), pressure and internal structure of the valve. For

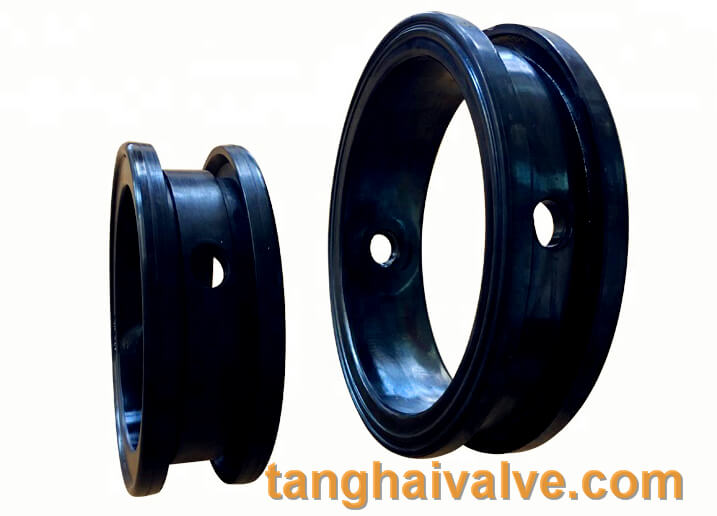

soft sealing marine valve, rubber sealing, valve seat parts

different occasions, the selected seals are also different. Valve seals can generally be divided into two categories: soft seals and hard seals. Users should have a detailed understanding of their codes, operating temperature, pressure, medium and other parameters.

Comparison table of valve sealing material usage range:

Valve sealing material and valve sealing material use range:

Rubber (X) Nominal pressure PN ≤ 1 MPa, operating temperature t ≤ 150℃, applicable valves: globe valves, diaphragm valves, butterfly valves, check valves, etc.

Nylon (N) Nominal pressure PN ≤ 32 MPa, operating temperature t ≤ 90°C, applicable valves: globe valves, ball valves, etc.

PTFE (F) Nominal pressure PN ≤ 6.4 MPa, operating temperature t ≤ 180°C, applicable valves: globe valves, ball valves, gate valves, diaphragm valves, butterfly valves, check valves, etc.

Bus alloy (B) Nominal pressure PN ≤ 2.5 MPa, operating temperature t ≤ 150°C, applicable valves: stop valves for ammonia, etc.

Ceramic (G) Nominal pressure PN ≤ 1.6 MPa, operating temperature t ≤ 150°C, applicable valves: ball valves, plug valves, etc.

Enamel (C) Nominal pressure PN ≤ 1.0 MPa, operating temperature t ≤ 80°C, applicable valves: globe valve, diaphragm valve, check valve, discharge valve, etc.

Copper alloy (T) Nominal pressure PN ≤ 1.6 MPa, operating temperature t ≤ 200℃, applicable valves: gate valve, globe valve, check valve, plug valve, etc.

Stainless steel (H) Nominal pressure PN ≤ 32 MPa, operating temperature t ≤ 450°C, applicable valves: globe valves, ball valves (medium and high pressure valves), etc.

Nitrided steel (D) Nominal pressure PN ≤ 10 MPa, operating temperature t ≤ 540℃, applicable valves: power station gate valves, only for general use

Cemented carbide (Y) Nominal pressure (PN) and operating temperature (t) are determined according to the material of the valve body. Applicable valves: high pressure, ultra high pressure valves, high temperature and low temperature valves

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news/knowledge:

Valve seal (ring) material usage range comparison table;

Comparison of bellows globe valve and ordinary globe valve;

Applicable occasions and operation method of ball valve;

How to choose a valve in the chemical industry

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.