The structure and connection of the American standard valve

American standard valves mainly have API and ASME standards. ASTM and ASTM are material standards; valves designed, manufactured, produced and tested according to American standards are called American standard valves.

The American standard valve is a control component in the fluid conveying system. It has the functions of cut-off, regulation, diversion, prevention of reverse flow, voltage stabilization, diversion or overflow and pressure relief; the valve used in the fluid control system is cut off from the simplest American standard. There are many types and specifications of American standard valves used in extremely complex automatic control systems. Valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media. Valve types: gate valve, knife gate valve, check valve, butterfly valve and others.

The structure types:

| code | structure type | explaination | standard | face to face |

| C | BB-BG-OS&Y | bolted bonnet, bolted gland, outside screw & yoke | API602/API602M | ASME B16.10 |

| D | BB-BG-OS&Y | bolted bonnet, bolted gland, outside screw & yoke | API603/API603M | ASME B16.10 |

| E | BB-BG-OS&Y-N | bolted bonnet, bolted gland, outside screw & yoke-needle type | API602M | ASME B16.10 |

| G | BC-PISTON-LIFT | (BOLTED BONNE,PISTON-LIFT) | API602M | ASME B16.10 |

| H | BC-PISTON-LIFT | (BOLTED BONNE,PISTON-LIFT) outside screw & yoke | API603M | ASME B16.10 |

| B | BB-BG-OS&Y-W | BOLTED BONNET,BOLTED GLAND,OS&Y ,BELLOWS SEAL TYPE) | API600M | ASME B16.10 |

| L | BB-BG-OS&Y-L | BOLTED BONNET,BOLTEDGLAND ,OS&Y ,CRYOGENIC SERVICE SRRUCTURE | ASME B16.34 | ASME B16.10 |

| 1 | BC-SWING | (BOLTED BONNET,SWING) | API600M | ASME B16.10 |

| 2 | PS-PISTON-LIFT | (PRESSURE SEAL BONNET,PISTON-LIFT) | API600M | ASME B16.10 |

| 3 | WAFER TYPE | (WAFER CHECK VALVE) | API594 | API594 |

| 4 | TILTING-DISC | (TILTING-DISC TYPE CHECK VALVE) | API600M | ASME B16.10 |

| 5 | BB-BG-OS&Y-F | (BOLTED BONNET,BOLTED GLAND,OS&Y,WITH SPECCIAL PACKING) | API600/API600M | ASME B16.10 |

| 6 | BB-BG-OS&Y | (BOLTED BONNET,BOLTED GLAND,OS&Y) | API600/API600M | ASME B16.10 |

| 7 | BB-BG-OS&Y-H | (BOLTED BONNET,BOLTED GLAND,OS&Y,WITH BLOMING HOLE) | API600/API600M | ASME B16.10 |

| 8 | PS-BG-OS&Y | (PRESSURE SEAL BONNET,BOLTED GLAND,OS&Y) | API600/API600M | ASME B16.10 |

| 9 | PS-COVER SWING | (PRESSURE SEAL BONNET, SWING) | API600/API600M | ASME B16.10 |

| M | BB-BG-M-SEAL | PRESSURE SEAL BONNET,BOLTED GLAND,moving sealing | API600M | ASME 16.10 |

connection types:

| code | connection type | explaination |

| S | SW | SOCKET WELDED |

| T | NPT | 60° Taper pipe thread/NATIONAL TAPER PIPE THREAD |

| G | Rc | 55° TAPER PIPE THREAD |

| R | RF | RAISED FACE |

| J | RJ | RING JOINT |

| W | BW | BUTT-WELDED |

| P | PIPE | EACH ENDWITH A 150mm SHORT PIPE |

| F | MF(F) | MALE-FEMALE FACE(FEMALE) |

| A | RF-NPT | one side RF, one side NPT |

Tianjin Tanghai Valve Manufacturing Co., Ltd. is one of the largest butterfly valve manufacturers in China. It was founded in 2006. Its predecessor was Tanghai Valve Manufacturing Factory. Now we have our own independent R & D, manufacturing, assembly and warehousing workshops; we have professional pre-sale and after-sale technical support and perfect services.

Our products use advanced manufacturing technology, and strictly conform to API, DIN, BS, EN, ISO, GB and other international standards. The main products are butterfly valves, gate valves, check valves, globe valves, valve parts (Valve body, Valve disc, Valve shaft, Valve seat…), etc. Our products are widely used in various fields such as marine industry, shipbuilding, petrochemical, metallurgy, water treatment, fire fighting, water supply and drainage, etc. The company has won unanimous recognition and praise from customers with high quality and good reputation.

Tianjin Tanghai Valve Manufacturing Co., Ltd. is one of the largest butterfly valve manufacturers in China, main products are butterfly valves, check valves, gate valve and globe valves. Key words: butterfly valve, lug type butterfly valve, wafer type butterfly valve, U-type butterfly valve, double flange butterfly valve, gate valves, check valves, globe valves, valve parts (Valve body, Valve disc, Valve shaft, Valve seat…)

URL: http://www.tanghaivalve.com

Name: Harry Li

Email: harry@tanghaivalve.com

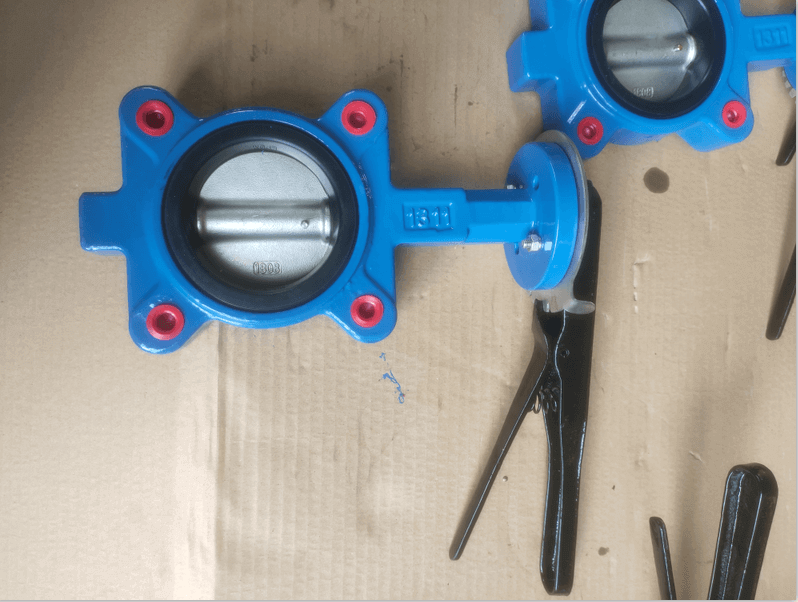

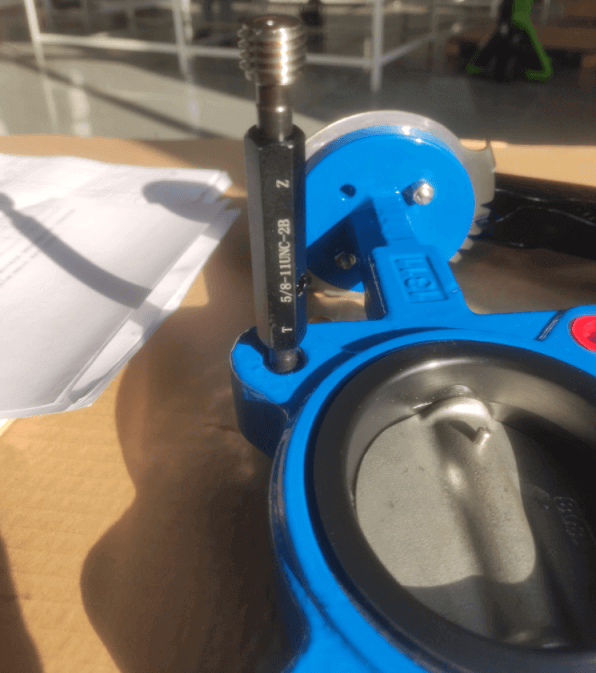

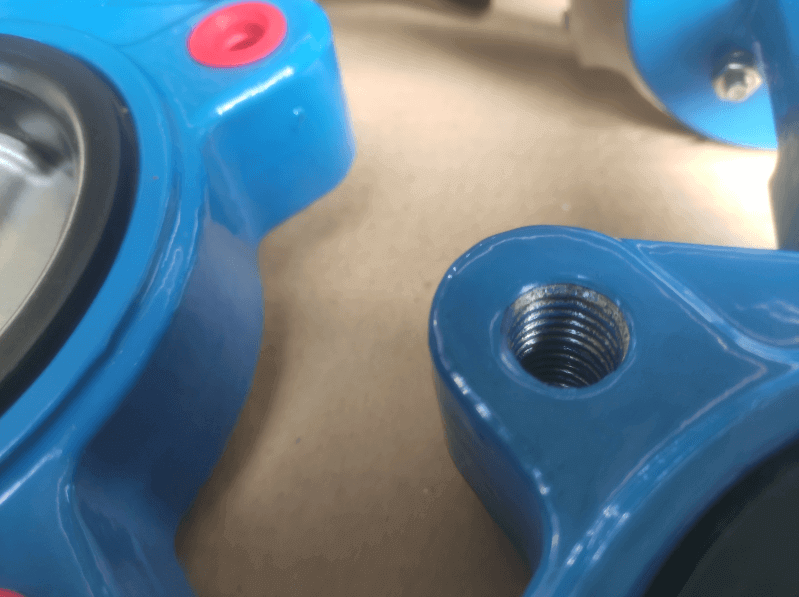

Wafer butterfly valve-PN20-WCB-ANSI-150 (4)

Wafer butterfly valve-PN20-WCB-ANSI-150 (2)

Wafer butterfly valve-PN20-WCB-ANSI-150 (6)

Wafer butterfly valve-PN20-WCB-ANSI-150 (1)

rising stem gate valve-OS&Y

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.