What is the principle of triple eccentric butterfly valve

Triple eccentric butterfly valve is a kind of butterfly valve with outstanding performance in industrial pipelines. According to the sealing form, triple eccentric butterfly valve belongs to the category of hard sealing butterfly valve. Therefore, the triple eccentric butterfly valve has the characteristics of a hard-sealed butterfly valve, which is

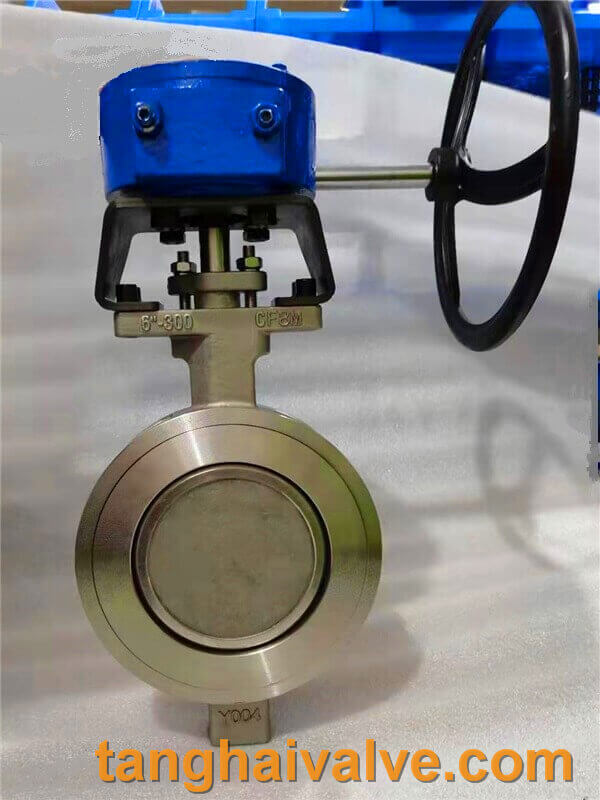

D943H-16C-metal seated stainless steel electric triple offset butterfly valve

resistant to high temperature, erosion, and has a long service life. And because the triple eccentric butterfly valve directly welds the high temperature corrosion resistant alloy material on the valve seat surface, the valve also has the same excellent sealing performance as the soft sealing butterfly valve. So what is the principle of triple eccentric butterfly valve? What are the three eccentricities of the triple eccentricity? Why use a triple eccentric structure?

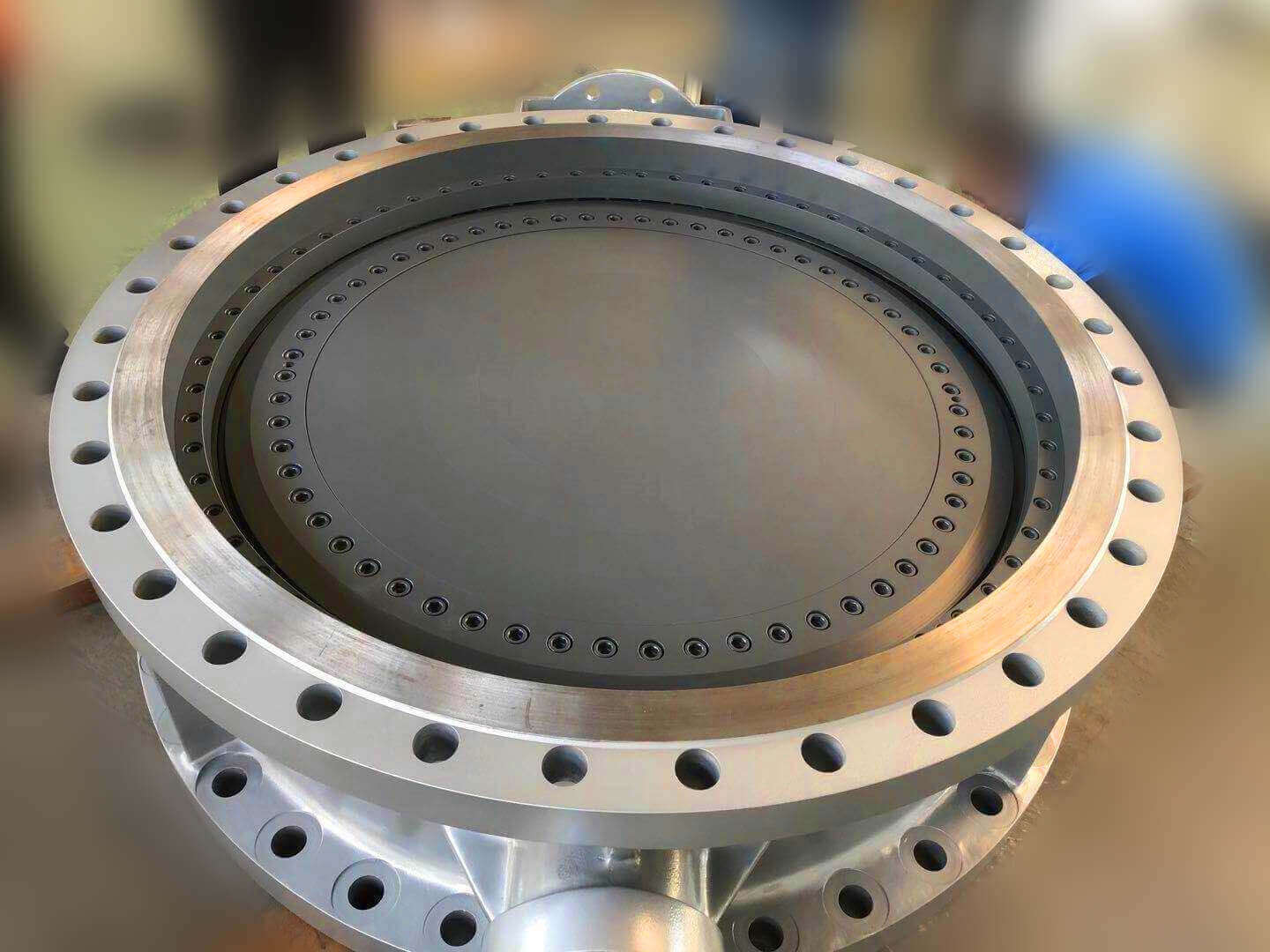

The sealing surface of the triple eccentric butterfly valve is an inclined conical surface. The valve seat of the valve body is in contact with the sealing ring of the butterfly plate. Its working principle is to drive the movement of the butterfly plate by operating the transmission device. During the movement of the butterfly plate, its sealing The ring is in full contact with the valve seat because of the elastic deformation to achieve the seal.

A prominent feature of the triple eccentric butterfly valve is that the sealing structure of the valve is changed. It is no longer a traditional position seal, but a torsion seal, that is to say, it does not rely on the elastic deformation of the valve seat to achieve sealing, but relies on the sealing surface of the butterfly plate. The contact surface pressure with the valve

triple eccentric butterfly valve-wafer-lug-double flange-welded (5)

seat is used to achieve the sealing effect, which also solves the problem of large leakage of the metal valve seat, and because the contact surface pressure is proportional to the medium pressure, the triple eccentric butterfly valve has a strong high pressure and high temperature resistance.

Three eccentric butterfly valve three eccentric

The first eccentricity: the deviation from the plane of the sealing surface to the centerline of the valve stem;

The second eccentricity: the distance from the centerline of the valve body to the centerline of the stem;

The third eccentricity: there is an included angle between the center line of the cone surface where the sealing surface of the valve body is located and the center line of the valve body channel.

Reasons for using triple eccentric structure

The use of triple eccentric structure can reduce the friction between the sealing surface of the disc and the sealing surface of the valve body when opening or closing, so that the disc can quickly disengage or release the valve seat when the triple eccentric butterfly valve is opened or closed, reducing the operation time. torque, the operation is more labor-saving and light, and the service life of the sealing surface of the butterfly valve is increased.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of triple eccentric butterfly valve:

Related news/knowledge:

Advantages and Disadvantages of Triple Eccentric Butterfly Valves

Properties of triple eccentric butterfly valve

What is a triple eccentric metal seated butterfly valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.