Common failures of butterfly valves and the characteristics of installation

Common errors of butterfly valves:

The rubber elastomer in the butterfly valve will tear, wear, aging, perforate or even fall off during continuous use. The traditional thermal vulcanization process is

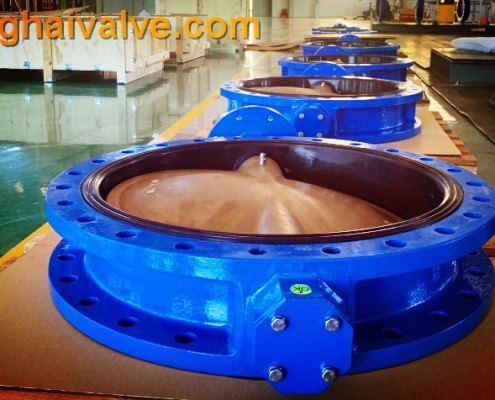

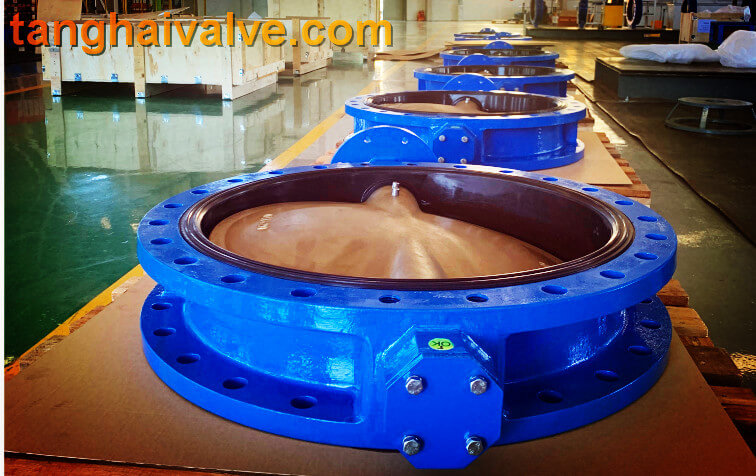

Double flange butterfly valve (16)

difficult to meet the needs of on-site repair. Special equipment is used for repair, which consumes a lot of heat and electricity, which takes time and effort. Today, we use new method gradually of adopting polymer composite materials to replace traditional methods. The superior adhesion and excellent wear and tear resistance of its products ensure that the repair cycle reaches or even exceeds the life cycle of new parts, greatly reducing downtime.

Installation and maintenance of butterfly valves:

1. During installation, the valve disc should stop at the closed position.

2. The opening position should be determined according to the rotation angle of the butterfly valve disc.

3. Butterfly valves with bypass valves should be opened before opening.

4. The installation should be carried out according to the manufacturer’s installation instructions. The heavy butterfly valve should be installed with a solid foundation.

Construction and installation points

1. The installation position, height, and direction of entrance and exit must meet the design requirements, and the connection should be firm and tight. The handles of all kinds of manual valves installed on thermal insulation pipes must not be downward.

2. The valve must be visually inspected before installation, and the nameplate of the valve should comply with the customer’s national standards. For valves with a working pressure greater than 1.0 MPa and acting as a shut-off on the main pipe, strength and tightness performance tests should be carried out before installation, and qualified before use. During the strength test, the test pressure is 1.5 times the nominal pressure, the duration is not less than 5min, and the valve housing and packing should be leak-free. During the tightness test, the test pressure is 1.1 times the nominal pressure; the test pressure lasts no less than 120 seconds during the test, and the valve flap sealing surface is qualified as no leakage.

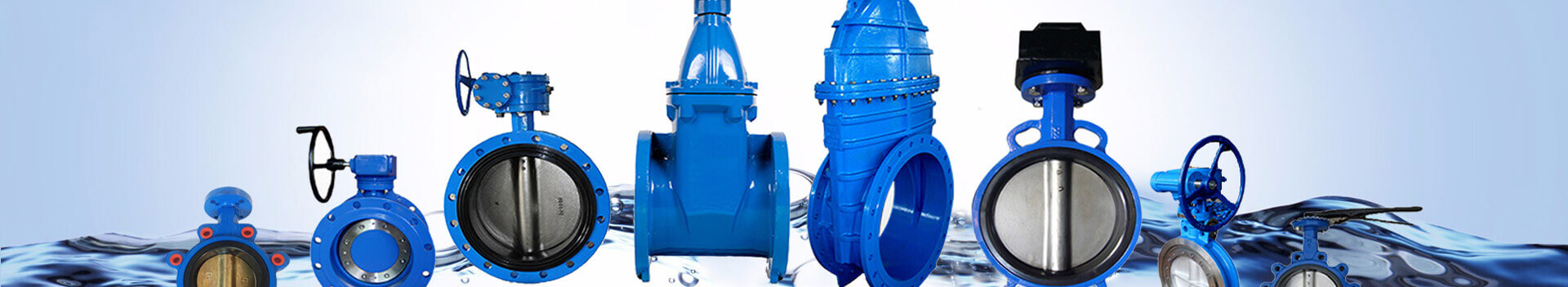

Tianjin Tanghaidongyang valve Co., Ltd. is one of the largest butterfly valve manufacturers in China, main products are butterfly valves, check valves. Products range: butterfly valve, lug type butterfly valve, wafer type butterfly valve, U-type butterfly valve, double flange butterfly valve, gate valves, check valves, globe valves, valve parts (Valve body, Valve disc, Valve shaft, Valve seat…)

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

related news /knowledge:

What is butt welding? (6)- Flash butt welding of common metals;

Hard seal installation method of ball valve;

What is assembly error and how to control it?;

What is machining accuracy, machining error, tolerance?;

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.