Advantages of the handle butterfly valve of Tanghai valve manufacturer

What are the advantages of handle butterfly valve? To understand this, let’s first understand the handle butterfly valve. The handle butterfly valve is a kind of manual butterfly valve. The common materials for making the handle butterfly valve are gray cast iron, ductile iron, cast steel, stainless steel, etc. The handle butterfly valve is the most common pipeline accessory in the pipeline system. It is generally required to be installed horizontally, and the

marine valve; butterfly valve; check valve; gate valve; manufacturer in China

butterfly plate of the handle butterfly valve is installed in the diameter direction of the pipeline. The switch operation is also very simple and convenient. Rotate the handle, the handle drives the valve stem to rotate, and the circular butterfly plate rotates around the valve stem. Usually, it is turned on by turning counterclockwise, and turned off by turning clockwise. The rotation angle is 0°-90°. Between °, when the disc rotates to 90°, the valve is fully open.

The handle butterfly valve has a simple structure and small volume. It can be seen in the water treatment, urban water supply and drainage, petroleum, chemical industry, and even the cooling water system of the thermal power station.

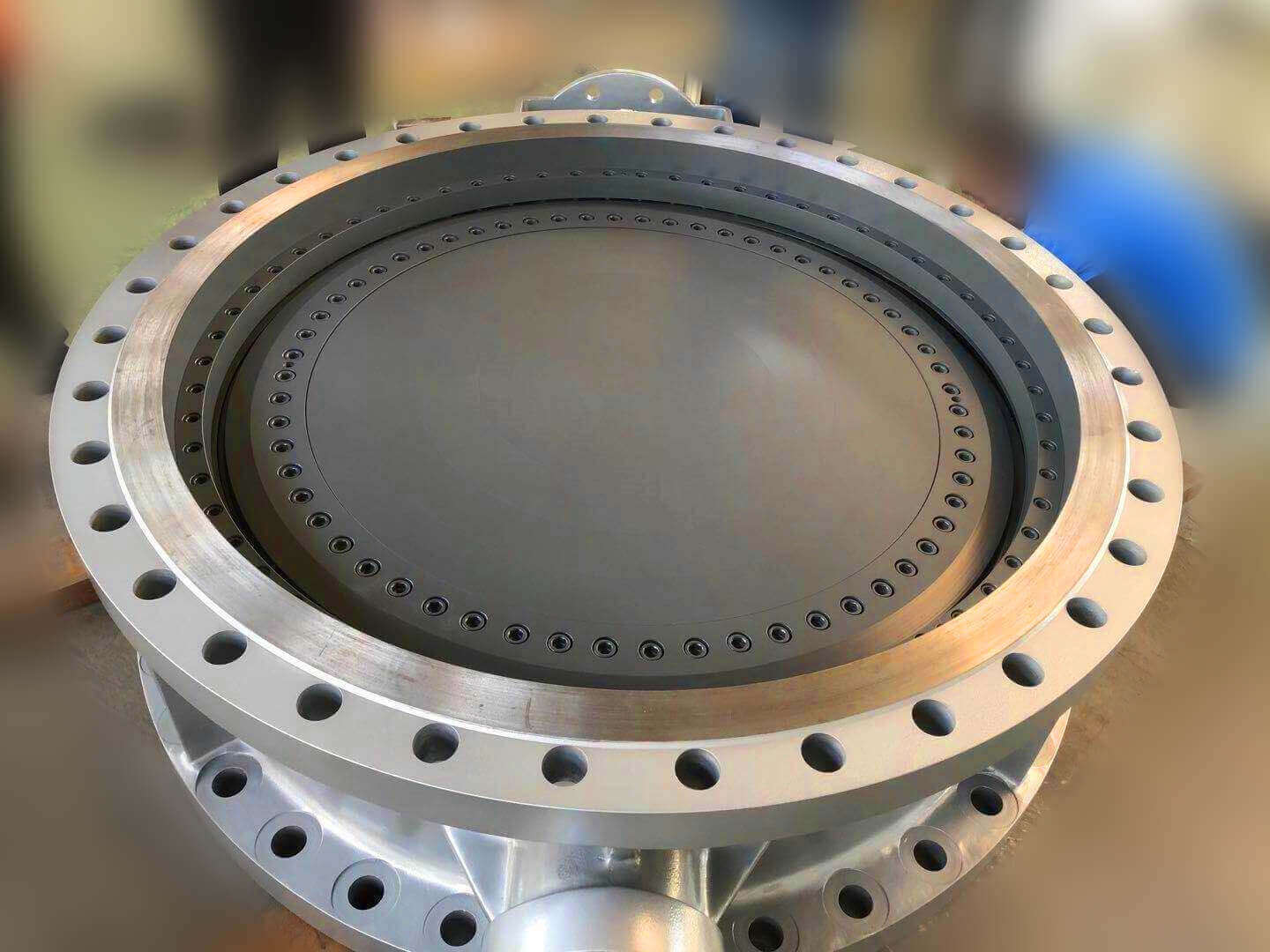

JIS 10K-wafer butterfly valve-backup seat (4)

Tanghai Valve is committed to providing high-quality valve products and services to the society. The handle butterfly valve has always been our flagship product and one of the most satisfied products for customers. So in the highly competitive valve market, what are the advantages of the handle butterfly valve of Tanghai valve manufacturers?

1. Different handle design

The handle end of the handle butterfly valve adopts a humanized arc structure, which will not let the operator hurt his hand during operation, and it is more labor-saving to open and close.

2. Stainless steel handle bolts and disc pins

The bolts used on the handle and the pins on the butterfly plate are all made of stainless steel, and the corrosion resistance is more than 10 times that of ordinary products, making it safer to use.

3. Reinforcement at both ends of the butterfly plate

In order to prevent the instantaneous impact of the flowing medium to break the butterfly plate after the butterfly valve is installed, four reinforcing ribs are specially added at both ends of the butterfly plate.

4. Valve seat for vulcanization process

In order to ensure the sealing performance of the valve, the valve seat adopts the vulcanization process, which makes the valve seat and the valve body fit better, and the sealing surface is wider, which is more reliable than the sealing performance of ordinary butterfly valves.

5. Valve body painted with epoxy paint

If the butterfly valve is installed outdoors, the valve body is exposed, and it is easy to rust, which affects the service life of the valve. For this reason, Tanghai Valve specially sprays the valve body with epoxy resin paint, which makes the valve body of the butterfly valve more resistant to oxidation and can be safely installed outdoors.

6. Pressure test higher than the national standard

Each butterfly valve of Tanghai Valve must pass a pressure test higher than the national standard before leaving the factory.

7. Universal universal valve body

Tanghai Valve’s wafer butterfly valve adopts universal universal body, which can meet the national standard, German standard, American standard, Japanese standard, Korean standard, British standard and other standards at the same time, so as to meet the needs of different customers.

8. The natural rubber content of the valve seat exceeds 40%

The natural rubber content of the valve seat of the soft sealing butterfly valve is more than 40%, which has a longer service life than ordinary rubber.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of center-lined butterfly valve:

Related news/knowledge:

Features of Stainless Steel Valves

Purchasing precautions for handle butterfly valves

Sealing Surface Structure of Handle Wafer Type Butterfly Valve

Structural Characteristics and application of Centerline Butterfly valves

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.