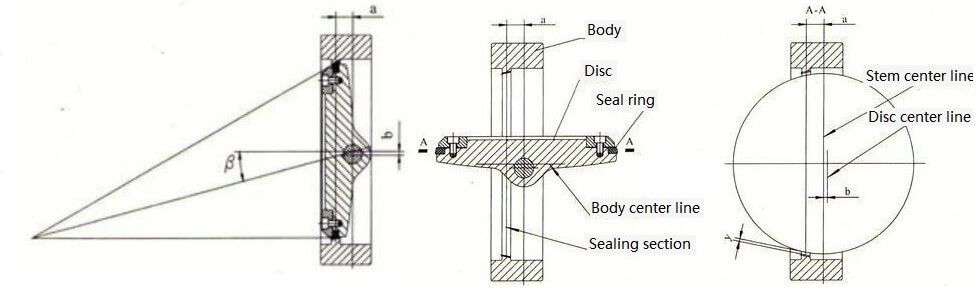

Structure diagram of triple eccentric butterfly valve

With the advancement of science and technology and the improvement of production technology, the industrial requirements for butterfly valves are no longer simple cut-off and adjustment of normal temperature and low pressure media, but also require butterfly valves to play a role in high temperature and high pressure environments. For this reason, the triple eccentric butterfly valve was born, and has replaced the application of some gate valves, globe valves, ball valves and other valves in the industry. What is the structure of the triple eccentric butterfly valve? What are the structural characteristics of the triple eccentric butterfly valve?

Triple eccentric butterfly valve structure

triple eccentric butterfly valve structure diagram

The triple eccentric butterfly valve is a hard-sealed butterfly valve. This kind of butterfly valve adopts the triple eccentric sealing structure and has the characteristics of compact structure, fast opening and closing speed, labor-saving and light operation, and reliable sealing performance. It is suitable for pipelines under various working conditions. media flow. Three eccentric butterfly valves are currently widely used in electric power, metallurgy, petroleum, chemical industry, urban heating and other industries.

D673H-16C-stainless steel pneumatic triple eccentric butterfly valve

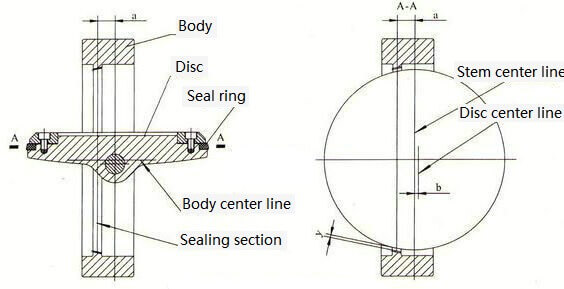

1. The shape of the sealing surface of the valve body and the butterfly plate is an elliptical cone, and the center line of the sealing cone surface of the valve body and the butterfly plate has an eccentric angle c° with the center line of the valve body channel.

2. There is an axial eccentricity a between the center line of the valve body and the disc sealing surface and the valve stem shaft.

3. There is a radial eccentricity b between the center line of the valve stem and the center line of the valve body.

Triple eccentric butterfly valve sealing principle

On the basis of the double eccentric sealing butterfly valve, the center line of the valve seat and the center line of the valve body form a β angle offset. When the triple eccentric sealing butterfly valve is in a fully open state, the sealing surface of the valve plate will be completely separated from the sealing surface of the valve seat. , and the same gap y as the double eccentric sealing butterfly valve is formed between the sealing surface of the valve plate and the sealing surface of the valve seat. When the valve plate of this type of butterfly valve is opened from 0° to 90°, the sealing surface of the valve plate will be separated from the sealing surface of the valve seat at the moment of opening. When it is closed at 90° to 0°, only at the moment of closing, the sealing surface of the valve plate will contact and press the sealing surface of the valve seat.

This is the three eccentricities of the triple eccentric butterfly valve. So what are the characteristics of the triple eccentric butterfly valve structure?

1. The unique triple eccentric design, the friction coefficient between the valve body and the sealing surface of the disc is extremely small, which reduces the wear of the sealing surface and prolongs the service life of the valve.

2. The eccentric design reduces the opening and closing torque of the valve, and the opening and closing is more rapid.

3. The valve body and the disc are directly conical, as shown in the figure above, when the disc is closed, the medium exerts pressure on the disc. The conical design makes the valve more tightly closed, realizing automatic sealing and greatly improving Improve the sealing performance and truly achieve zero leakage.

4. It can be equipped with different driving methods according to customer needs or working conditions, such as installing pneumatic and electric actuators to realize automatic operation of triple eccentric butterfly valves.

5. The sealing ring on the butterfly plate is made of stainless steel sheet and flexible graphite. It has the rigidity of metal and the elasticity of non-metal, and also makes the triple eccentric butterfly valve have the advantages of metal hard sealing and elastic sealing at the same time. Good sealing performance can be achieved in low temperature environment or high temperature working condition.

If you want to know more about triple eccentric metal hard sealing butterfly valve, please pay more attention to the official website of “Tanghai Valve”. If you have the needs of this valve, you are also welcome to inquire.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of triple eccentric butterfly valve:

Related news/knowledge:

Properties of triple eccentric butterfly valve

What is a triple eccentric metal seated butterfly valve

Application of double eccentric butterfly valve and triple eccentric butterfly valve

What is the principle of triple eccentric butterfly valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.