Introduction and Description of Pneumatic Butterfly Valves

This article gives an introduction and description of the pneumatic butterfly valve. Pneumatic butterfly valve is a control terminal installed on industrial pipelines. Like electric butterfly valve, it belongs to automatic control valve. Pneumatic butterfly valves are now widely used in petroleum, chemical, electric power, metallurgy and other industries. They are usually used in pipelines in these industries and are not suitable for manual operation.

D673H-16C-stainless steel pneumatic triple eccentric butterfly valve

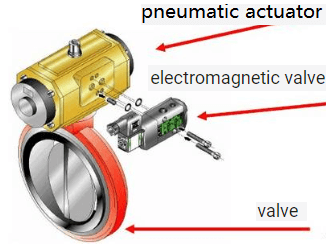

The working principle of pneumatic butterfly valve

The pneumatic butterfly valve absorbs dry and lubricated gases through positioners, solenoid valves or other equipment, controls them, and transmits these gases to the cylinder of the pneumatic actuator. This is the air source for the pneumatic actuator to work. When the cylinder is When the internal air source is introduced into the air chamber of the pneumatic actuator, the air pressure acts on the piston, and the generated thrust drives the output shaft to rotate, and at the same time drives the valve stem and the butterfly plate to rotate, thereby completing an opening and closing action of the butterfly valve. Adding a valve positioner to the pneumatic butterfly valve can also realize the precise opening adjustment of the butterfly valve. In addition, an intelligent positioner can also be used to connect with the field bus, so as to achieve the purpose of detecting the working state of the pneumatic butterfly valve and provide diagnosis.

Under the action of the pneumatic actuator, the pneumatic butterfly valve can open and close flexibly and quickly, which ensures the safety of the pipeline. It is a control valve that is used more in industrial pipelines. The parameters of the pneumatic butterfly valve can be divided into two parts, one is the basic parameters of the butterfly valve itself, and the other is the basic parameters of the pneumatic actuator.

Valve basic parameters

| Valve Name | Pneumatic Butterfly Valve |

| Working medium | liquid, gas, oil, etc. |

| Working temperature | -29—400℃ |

| Body Material | Cast Iron, Carbon Steel, Stainless Steel, Alloy Steel |

| Connection form | Flange, wafer, welding |

| Stroke | 60°90° |

| Fault position | Fault on, fault off, hold position |

| Flow characteristics | Equal percentage (EQ-%) |

Basic parameters of pneumatic device

| Air source pressure | 0.4-0.7mpa |

| Ambient temperature | -20-90℃ |

| Location of accessories | Air filter pressure reducing valve, valve positioner, electric/pneumatic converter, solenoid valve, air control reversing valve, pneumatic amplifier, quick exhaust valve, manual operating mechanism, etc. |

Installation and debugging of pneumatic butterfly valve

1. Before installing and using the pneumatic butterfly valve, thoroughly clean the valve body and pneumatic device of the butterfly valve.

2. Before installation, check whether the coating of the pneumatic butterfly valve is damaged. If any damage is found, please find a professional to repair it.

3. Like the electric butterfly valve, the installation area of the pneumatic butterfly valve is generally in a working condition with a certain risk factor. In this working condition, if the valve is to be moved, an accident may occur. At this time, the site must be covered with a suitable cover. Protect it.

4. The installation position of the solenoid valve should be as close as possible to the execution cylinder, and it must be as close as possible to the execution cylinder. The size of the air pipe is related to the air capacity. Before installing the pneumatic butterfly valve, the air intake hole and the solenoid valve must be kept clean. Cylinder actuators need to be lubricated.

5. The switch of the pneumatic butterfly valve must be too fast to avoid the pressure hitting the inside of the valve body and causing danger.

The above has made a simple price and description for the working principle, parameter information and installation and debugging of the pneumatic butterfly valve. If you have purchase requirements for the pneumatic butterfly valve, you are welcome to call the Tanghai Valve Hotline for consultation.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of center-lined butterfly valve:

Related news/knowledge:

Commonly used valve body material code description

Pneumatic butterfly valve installation instructions

Pneumatic butterfly valve working principle diagram

Working Principle of Pneumatic Gate Valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.