Precautions for installation of pinless wafer butterfly valve

The pinless wafer butterfly valve contains two connection methods, one is pinless and the other is wafer. A pinless butterfly valve is a pinless butterfly valve that does not use a pin to penetrate the connection between the valve plate and the valve stem. For comparison of pin butterfly valves and pinless butterfly valves, please refer to valve knowledge. The wafer butterfly valve is connected between two pipe flanges with stud bolts, without flanges.

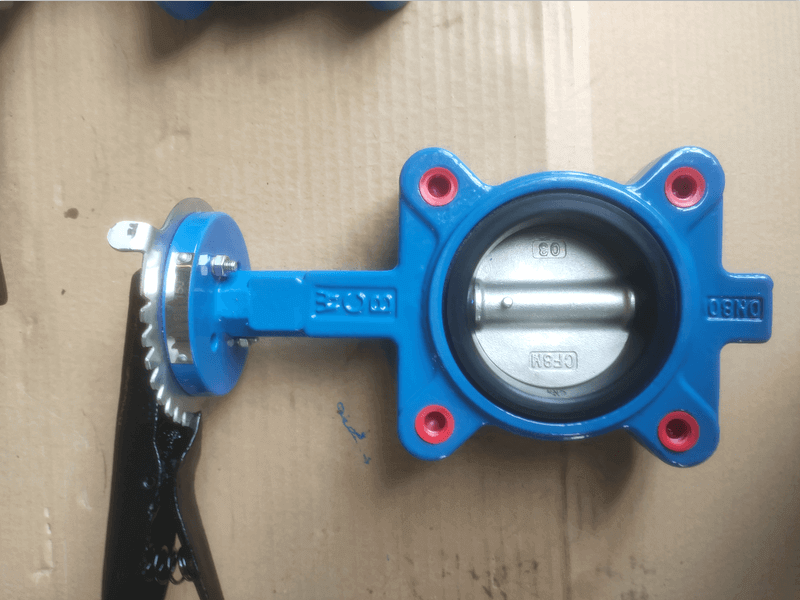

JIS 10K-wafer butterfly valve-backup seat (4)

Commonly used pinless butterfly valves include wafer type butterfly valves and flange type butterfly valves, so flange type butterfly valves are often compared with wafer type butterfly valves. The biggest difference between the two is the connection method during installation. Now let’s take a look at what to pay attention to when installing the pinless wafer butterfly valve.

1. During installation, the valve disc should be stopped in the closed position.

2. The opening position should be determined according to the rotation angle of the butterfly plate.

3. For the butterfly valve with bypass valve, the bypass valve should be opened before opening.

4. The installation should be carried out according to the installation instructions of the manufacturer, and the heavy-weight butterfly valve should be installed with a firm foundation.

5. The butterfly plate of the pinless wafer butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical passage of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, and the rotation angle is between 0-90°. When the rotation reaches 90°, the valve is fully open.

6. If the butterfly valve is required to be used as a flow control, the main thing is to select the size and type of the valve correctly. The structure principle of the butterfly valve is especially suitable for making large-diameter valves. Butterfly valves are not only widely used in general industries such as petroleum, gas, chemical, and water treatment, but also used in cooling water systems of thermal power stations.

The price of the pinless wafer butterfly valve is roughly 2/3 of that of the pinless flange butterfly valve, which is relatively cheap, but the sealing performance is not as good as that of the flange butterfly valve. When choosing imported valves, use wafer butterfly valves as much as possible because they are cheap and light in weight. One of its limitations is that there are no flanges at both ends of the valve body, and there are only a few guide bolt holes. The valve is connected to the end flange with a set of bolts/nuts. Compared with the flanged butterfly valve, it is much more convenient to disassemble, and the valve cost is lower, but the disadvantage is that one sealing surface has a problem, and both sealing surfaces have to be disassembled. The paired flanges of the clip-on type are butt welded and cannot be installed by socket welding.

The pinless wafer butterfly valve also has its own advantages, that is, it saves space, and try to use wafer butterfly valves when the piping position is tight. The biggest difference between the pinless wafer butterfly valve and the flangeless butterfly valve is that the wafer butterfly valve saves a pair of flanges, so the cost is relatively cheap, but it is not conducive to the disassembly and assembly of maintenance, etc., where permitted, priority Choose a wafer butterfly valve. Wafer butterfly valves are generally used in industrial pipelines with relatively low pressure and relatively safe transport media.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of center-lined butterfly valve:

Related news/knowledge:

Comparison of pin butterfly valve and pinless butterfly valve

What is a wafer type butterfly valve

electric wafer butterfly valve vs electric flange butterfly valve

Wafer type double disc swing check valve introduction

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.