Advantages and disadvantages of butterfly valve and structure diagram

Advantages and disadvantages of butterfly valve and structure diagram

The butterfly valve opening and closing part is a disc-shaped butterfly plate, which rotates around its own axis in the valve body to achieve opening and closing or adjustment. The butterfly valve is usually less than 900 from fully open to fully closed. The butterfly valve and the butterfly rod themselves are not self-locking. For the positioning of the butterfly plate, a worm gear reducer must be installed on the valve rod. The use of worm gear reducer can not only make the disc plate have self-locking ability, make the disc plate stop at any position, but also improve the operation performance of the valve.

ductile iron, DI, butterfly valve, manufacturer, center line, TH valve

The industrial butterfly valve is characterized by high temperature resistance, high applicable pressure range, large nominal diameter of the valve, the valve body is made of carbon steel, and the sealing ring of the valve plate uses a metal ring instead of a rubber ring. The large high temperature butterfly valve is made of steel plate welding, and is mainly used for flue ducts and gas pipes of high temperature media.

(1) Advantages of butterfly valve:

1. It is convenient and quick to open and close, labor-saving, low fluid resistance, and can be operated frequently.

Wafer and Lug type butterfly valve structures & parts

2. Simple structure, small size and light weight.

3. Mud can be transported, and the accumulation of liquid at the pipe mouth is the least.

4. Under low pressure, good sealing can be achieved.

5. Good adjustment performance.

(2) Disadvantages of butterfly valves:

1. The working pressure and working temperature range are small.

2. Poor airtightness.

(3) Installation and maintenance of butterfly valve:

1. During installation, the valve disc should be stopped in the closed position.

2. The opening position should be determined according to the rotation angle of the butterfly plate.

3. For the butterfly valve with bypass valve, the bypass valve should be opened before opening.

4. The installation should be carried out according to the installation instructions of the manufacturer, and the heavy-weight butterfly valve should be installed with a firm foundation.

Related knowledge: the principle of butterfly valve structure

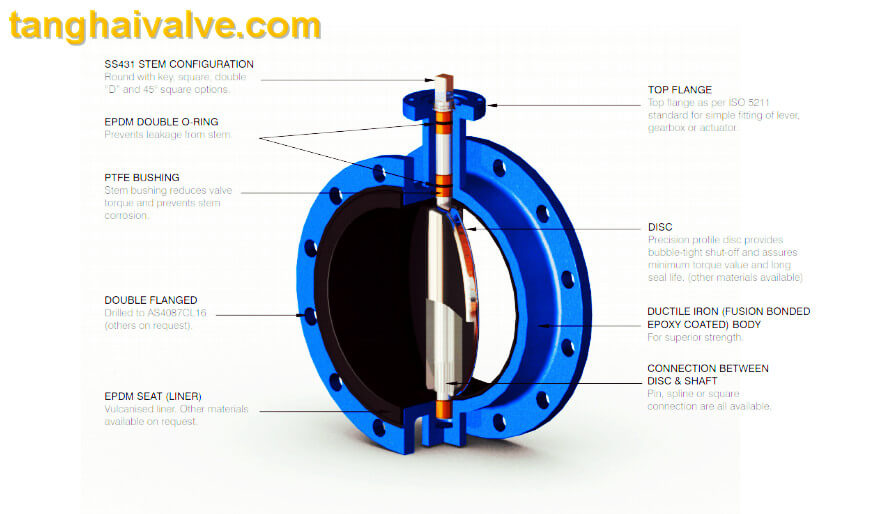

Double flange butterfly valve structure

Related products: Electric butterfly valve Pneumatic butterfly valve

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Related news /products:

Classification and advantages of gate valve;

Working principle diagram of electric butterfly valve;

The advantages and disadvantages of butterfly valves;

tanghaivalve.com

tanghaivalve.com

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.