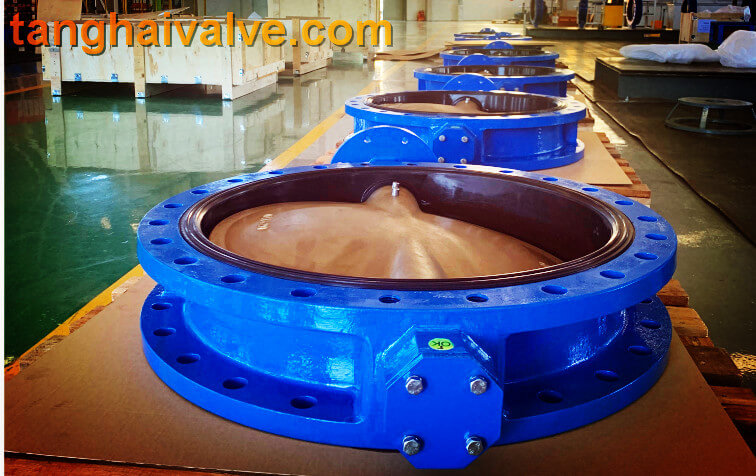

Two-way triple eccentric butterfly valve

The two-way hard-sealed butterfly valve is a valve product that has been developed rapidly in recent years. From the earliest centerline butterfly valve to the later triple eccentric sealing butterfly valve to the current triple eccentric two-way sealing structure, the hard sealing butterfly valve has greatly reformed and improved its own sealing performance. In the course of this evolution and development, leading valve manufacturers have paid tremendous hard work and efforts.

cryogenic triple offset butterfly valve 1

Let’s first take a look at the sealing characteristics of the two-way hard-sealed butterfly valve. Its sealing material is forged with metal or materials with strong hardness. It has strong durability and longer service life than ordinary valve products. However, because of the material characteristics of the sealing surface, the sealing performance is worse than that of ordinary butterfly valves. Make it completely sealed. But now, with the improvement of technology, there have been the emergence of multi-layer hard sealing butterfly valves, which can achieve zero leakage and have the dual advantages of soft and hard sealing.

The seat sealing surface of the two-way hard sealing butterfly valve adopts alloy material butt welding form, high temperature resistance, easy to operate, and the opening and closing torque is transmitted to the valve stem without friction, which greatly improves the sealing performance of the sealed butterfly valve and prolongs its service life. Its main technical feature is the advantages of sealing two-way. This structure effectively compensates for the pressure of the medium, and can achieve zero-leakage sealing performance regardless of whether it is at low temperature or high temperature.

Science and technology are developing, and society is also progressing. In the past ten years of development, the two-way hard seal butterfly valve has made great progress in product development, performance, quality, reliability, and service. The market prospects are optimistic. In the future, valve manufacturers will also make greater efforts to continuously innovate and formulate development paths in terms of electricity, water, and materials. Speed up the elimination of low-efficiency and high-energy-consuming butterfly valve products, adjust the industrial structure, and promote the development and promotion of new technologies and products. At present, some long-established manufacturers already have their own multi-system butterfly valve products. If you want to purchase two-way hard-sealed butterfly valves, Tanghai Valve is your first choice.

Compared with ordinary butterfly valves, the two-way hard-to-hard seal butterfly valve has the biggest difference in that it does not require the installation direction, that is, the direction of its input and output is uncertain. Ordinary butterfly valves are one-way and have restrictions on the installation direction. In addition to this, there is another point to pay attention to when installing the two-way hard-to-hard seal butterfly valve, that is, it cannot be installed and used in places with too much pressure.

Why can’t the two-way hard-to-hard sealing butterfly valve be used in places with too much pressure? Now let’s take a look at the reasons:

1. Because the valve plate is in a normally open state, the sealing ring fixed on the valve plate is multi-layered, that is, multi-layer soft and hard stacked sealing ring. In the normally open state, the medium will flush its sealing surface positively. If the pressure is too high, the soft sealing tape in the metal sheet sandwich will be easily washed away and cause leakage.

2. At the same time, because the overall structure of the valve plate of the two-way hard-to-hard seal butterfly valve is generally thicker, the flow resistance is also relatively large. If it is installed in a place with high pressure, the flow resistance and friction can be imagined, and the damage to the sealing surface will be great.

3. Because this product is a two-way seal, the product seal is mainly to press the valve plate against the valve seat through the torque of the transmission device. The greater the pressure, the tighter the seal, but it should be in a positive flow state at this time. But if the medium in the flow channel flows backwards, if it is installed in a pipeline position with too much pressure, it is easy to cause the positive pressure of the seal between the valve plate and the valve seat to be less than the medium pressure, and leakage will occur.

The two-way hard-to-hard sealing butterfly valve has many advantages, including: it is not hindered by forward pressure and reverse pressure, and can be reliably shut off; the two sealing surface materials of the sealing pair can choose different functional materials according to different hardness; there is automatic The centering function can automatically overtravel to compensate for wear. In addition, a series of advantages such as small size, light weight, convenient transportation, installation, maintenance and repair, and reliable operation make the two-way hard-to-hard seal butterfly valve more and more popular in the market. If you have relevant needs, please consult Tanghai Valve and choose your suitable valve product.

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

Video of triple eccentric butterfly valve: https://youtu.be/AkRwg2X1Wh0

Related news/knowledge:

Problems Existing in the Use of Triple Eccentric Butterfly Valves

Structural characteristics & features of flanged butterfly valves

Comparison of bellows globe valve and ordinary globe valve

The difference between knife gate valve and ordinary gate valve

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.