Flange telescopic butterfly valve application | advantages and disadvantages | installation instructions

Flange telescopic butterfly valve application|advantages and disadvantages|installation instructions

Flange telescopic butterfly valve application:

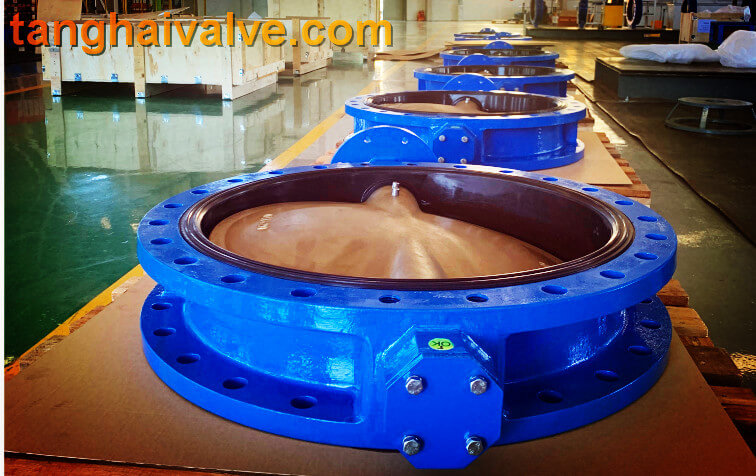

The butterfly plate of the flange telescopic butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical passage of the telescopic butterfly valve body, the disc-shaped butterfly plate rotates around the axis, and the rotation angle is between 0° and 90°. When the rotation reaches 90°, the valve is fully opened. Applicable temperature≤80℃, used in petroleum, chemical, food, medicine, textile, papermaking, electric power, water supply and drainage, gas pipelines, as the function of regulating flow and intercepting medium, and has the function of compensating for thermal expansion and contraction of pipelines.

Double flange butterfly valve (16)

Advantages and disadvantages of flange telescopic butterfly valve:

Flange retractable butterfly valve (the structural length can be extended within a certain range), which not only brings convenience for valve disassembly, but also relieves pipeline stress and protects the valve. At the same time, it also condenses the installation method of butterfly valve plus retractor, and space More compact. Normally, this type of valve does not require special maintenance, and only needs to be regularly observed for leakage and pull-off in the telescopic part. The initial cost of flange expansion butterfly valve is lower than the installation method of flange butterfly valve plus expansion, but considering the maintenance cost in the future, the gain is not worth the loss.

If the sealing part of the butterfly valve is damaged and the sealing ring cannot be replaced and the butterfly valve needs to be scrapped, then the telescopic part will be scrapped together, resulting in greater loss. For example, when the sealing part of the butterfly valve needs maintenance, only the compression and expansion part cannot realize the valve-free online maintenance. However, the installation method of the butterfly valve and the expansion device has a great advantage. Only the expansion device needs to be removed, that is, manual Large maintenance space to realize valve free maintenance (butterfly valve is heavy, retractor is light, and labor intensity is low).

Precautions for installation of flange telescopic butterfly valve:

1. It is strictly forbidden to disassemble the butterfly valve of the disintegrated telescopic flange at the pipeline construction site; it is strictly forbidden to lengthen and shorten the telescopic butterfly valve repeatedly at the site.

2. The pipes at both ends of the telescopic valve must be concentric, and the two flange surfaces on the pipe must be parallel;

3. Flange fixing bolts should be tightened symmetrically, please do not forcibly tighten flange fixing bolts unilaterally;

4. The telescopic tube is installed behind the valve;

5. The expansion part of the expansion valve shall not be installed at the corner of the pipeline or at the end of the pipeline.

6. The telescopic flange butterfly valve must be placed flat before installation, and do not bump it at will;

7. The structural length of the telescopic flange butterfly valve is the minimum length when it leaves the factory, and when installed, it is pulled to the installation length (ie the design length);

8. When the length between the pipelines exceeds the installation length of the telescopic butterfly valve, please adjust the pipeline interval and do not force the telescopic valve to avoid damage to the telescopic valve;

9. The butterfly valve of the telescopic flange butterfly valve can be installed at any position. When used for temperature compensation, after the installation of the pipeline, brackets should be added along the two ends of the pipeline axis to prevent the telescopic valve telescopic tube from being pulled out. The support force of the bracket is calculated according to the following formula , It is strictly forbidden to remove the bracket during operation;

10. The telescopic flange butterfly valve does not do temperature compensation. At the same time, it is only used for installation, replacement, and maintenance. When the valve is convenient for use, it can be limited by bolts, and the telescopic flange butterfly valve can be clamped symmetrically to prevent the telescopic tube from being pulled out and damaging the telescopic butterfly valve and piping devices or buildings. Things. The bolt diameter can be calculated according to the flange bolt diameter, its bolt strength and test pressure and pipeline tension, according to the above formula. The limit bolts are strictly prohibited to be removed during operation (bolts are provided separately).

TH Valve is a professional manufacturer of butterfly valve, gate valve, check valve, globe valve, knife gate valve, ball valve with API, JIS, DIN standard, used in Oil, Gas, Marine industry, Water supply and drainage, fire fighting, shipbuilding, water treatment and other systems, with Nominal Diameter of DN50 to DN1200, NBR/EPDM/VITON, Certificates & Approvals: DNV-GL, Lloyds, DNV, BV, API, ABS, CCS. Standards: EN 593, API609, API6D

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.